Wittmann 4.0

Wittmann 4.0

Smart Machine

Smart WorkCell

Smart Services

Smart Production

Smart Machine

The basic prerequisites for a stable injection molding process with varying environmental conditions and equipment are precise, absolutely repeatable and adaptive injection molding machines and auxiliaries.

Smart WorkCell

Access for the injection molding machine to parameters and status of auxiliary units to enable intelligent response to changes. In this way, the Smart WorkCell offers yet another improvement in quality standards for the molded parts as well as complete data recording and traceability. With the Wittmann 4.0 network and the digital mold data sheet, "Plug & Produce" in production has come within reach.

Smart Services

Fastest troubleshooting with the help of WITTMANN BATTENFELD's Smart Services.

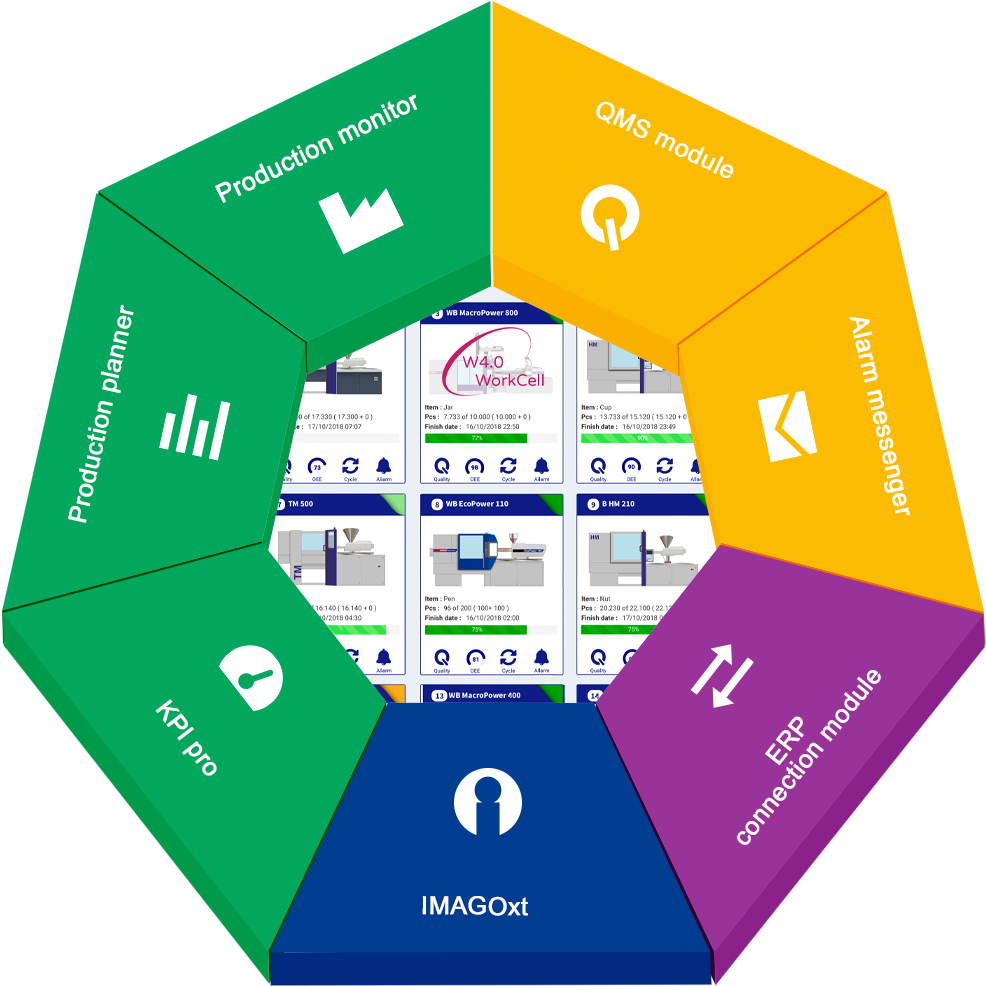

Smart Production

TEMI+ is the MES able to integrate all machines of an injection molding plant. This also includes older machine models with digital, Euromap 63 or modern Euromap 77/83 interfaces, as well as other brands of injection molding machines and, of course, the WITTMANN BATTENFELD WorkCells with Wittmann 4.0 router and the associated access to all connected auxiliaries.