Customer service

Customer service

Your reliable service partner

WITTMANN BATTENFELD USA customer service

Our Team or Parts and Service Professionals are committed to providing the best technical support available. For immediate assistance, please use the contact information referenced below regarding your respective product.

ALL SALES.: (860) 496-9603

Robots and Automation

Service

(8 am - 5 pm EST)

Tel.: (860) 496-9603 x115

Fax.: (860) 496-4921

Robot.Service.US@wittmann-group.com

After Hours Emergency Service: (860) 496-9603 x 699

Parts

(8 am - 5 pm EST)

Tel.: (860) 496-9603 x114

Fax.: (860) 496-4921

Robot.Parts.Us@wittmann-group.com

Material Handling and Auxiliary Equipment

Service

(8 am - 5 pm EST)

Tel.: (860) 496-9603 x168

Fax.: (860) 496-2037

Aux.Service.US@wittmann-group.com

After Hours Emergency Service: (860) 496-9603 x 677

Parts

(8 am - 5 pm EST)

Tel.: (860) 496-9603 x122

Fax.: (860) 496-2037

Aux.Parts.US@wittmann-group.com

Injection Molding Machines

Service

(8 am - 5 pm EST)

Tel.: (860) 496-9603 x214

Fax.: (860) 496-4921

IMM.Service.US@wittmann-group.com

After Hours Emergency Service: (860) 496-9603 x214

Parts

(8 am - 5 pm EST and CST)

Tel.: (860) 496-9603 x213

Fax.: (860) 496-4921

IMM.Parts.US@wittmann-group.com

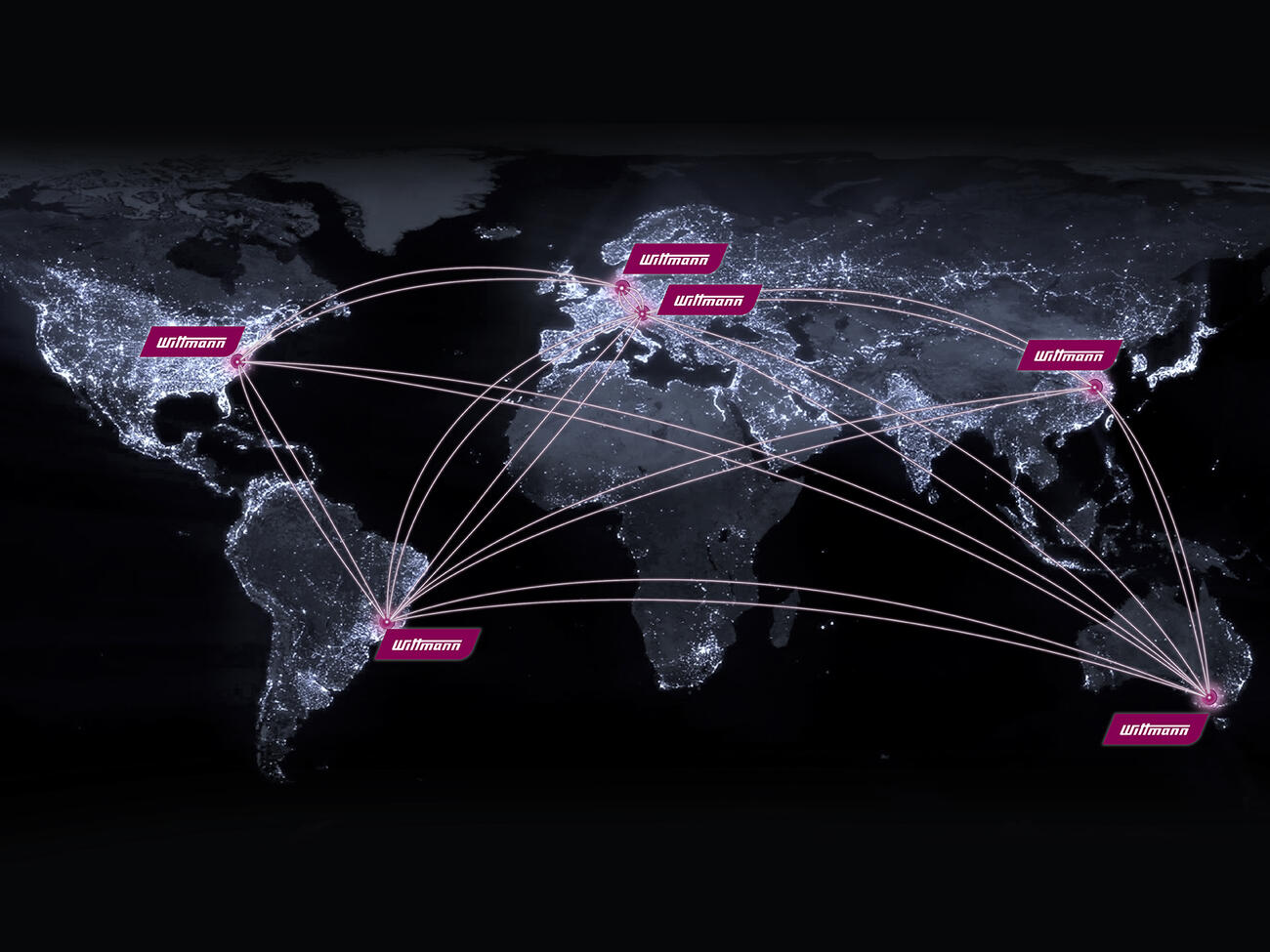

WITTMANN BATTENFELD customer service

Award-winning support for all your needs

You can rely on us! It is important to be able to fall back on strong service and support. We have a wide offering of service and support to help you can back up and running!

Technical customer service

Top quality from the very beginning: WITTMANN BATTENFELD’s service experts ensure worldwide that their customers` machinery performs optimally and retains its maximum value. Quickly, reliably and proficiently.

The technical customer service comprises a broad service offer:

- Complimentary Service-Hotline

- Web-Service 24/7

- Professional start-up

- WITTMANN BATTENFELD added-value program

- Conversions and retrofits

- Quality repairs for small auxiliaries

Service hotline

Our Service hotlines are a direct link to our service specialists, whom will find effective solutions for any problems.

Service: 8 am – 5 pm

Robots: (860) 496-9603 x 115

Material Handling: (860) 496-9603 x 168

Injection Molding Machines: (860) 496-9603 x 214

Have an emergency after hours? No problem! We have an after-hours emergency line for each division to help guide you to get back up and running!

After-hours Emergency Line:

5 pm – 8 am EST

Robots: (860) 496-9603 x 699

Material Handling: (860) 496-9603 x 677

Injection Molding Machines: (860) 496-9603 x 655

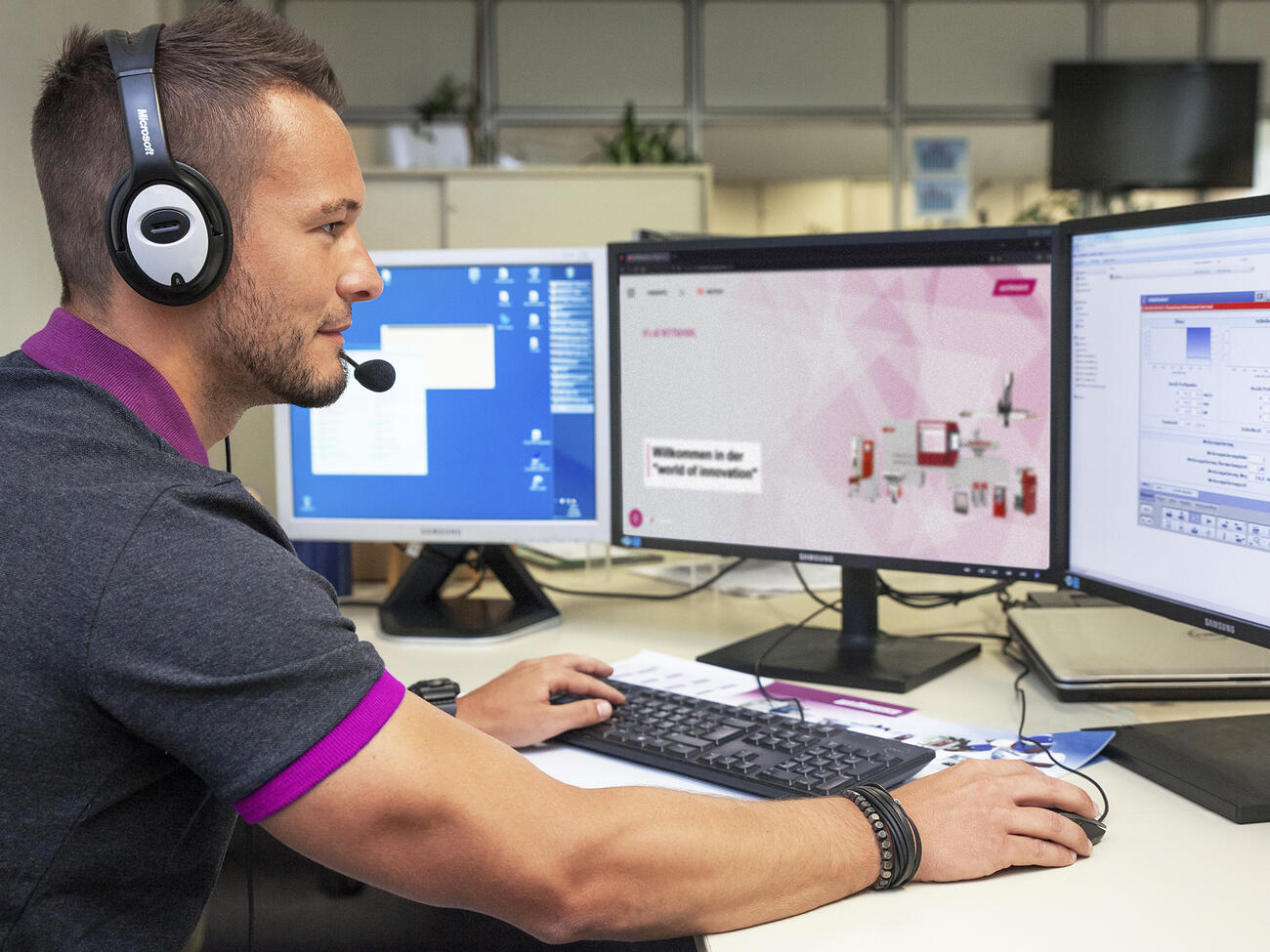

Web-Service 24/7

Our web-services is a fast, safe and secure way for a skilled technician from Wittmann Battenfeld to troubleshoot equipment remotely, provide mold set up assistance, training, and assistance with creating special programs. This feature is available 24/7 on B6 and B8 controlled Injection Molding Machines, R8 Robot controls, and M7.3 Material Handling controls.

Advantages

- Availability 24 hours, 7 days per week

- Servicing can be carried out quickly and cost-effectively via remote diagnostics without the need to have a service engineer on site

- Speed up service schedules and spare part deliveries due to exact error analysis via the Internet

- Reduction of on-site servicing to a minimum

Web-Service package

- Coaching during the orientation phase and for new staff.

- Remote diagnostics and instruction.

- Assistance in setting up new molds.

- Assistance in solving process technology problems.

- Process optimization and continuous data administration.

Technical details

- Separate Internet connection at the customer’s end, reliable data transfer between the machine and the web service center (VPN tunnel).

- Voice communication via the Internet (VoIP).

- Data transfer speeding up to 2 MB per second.

- Optional: video transmission and inclusion of additional specialists (subcontractors, etc.) by establishing several VPN tunnels.

Spare parts

WITTMANN BATTENFELD supplies its customers fast and reliably with high-quality original spare parts.

Our stocks are continuously monitored and replenished, so we can guarantee the delivery of all standard spare parts within two working days.

Spare part packages

We provide packages for Injection Molding Machines, Robots and individual Material Handling equipment and systems.

Upgrade packages

We offer a wide variety of upgrade packages for Injection Molding Machiens, Robots and Material Handling equipment and systems.

Process engineering consulting

Which molding machine is the right one to fulfill the customer’s requirements? Which mold will fit? Could I benefit from automation? Which process will get the best results? Should I use central or beside-the-press material handling?

We have engineers on staff to help with your entire injection molding process, from a single work cell to a complete new factory!

Moreover, we offer process technology counseling to optimize manufacturing processes, such as:

- Machine settings

- Process selection

- Mold design

- Material feeding technique

- Heating and cooling system

- Product handling

WITTMANN BATTENFELD can draw on many years of experience in screw and barrel manufacturing and offers a wide range of proven standard solutions to help you obtain the optimal plasticizing system.

Injection Molding Machine Processes:

- Internal gas pressure technology Airmould

- Multicomponent technology Combimould

- Light weight technology Cellmould

- In Mould Labeling IML

- In Mould Decoration IMD

- Wood injection molding IMWOOD (WPC`s)

- Insert technology

- Injection molding with liquid silicon LIM

- Powder Injection Molding PIM (MIM, CIM)

- Back Molding Technology

- Thermoset

- Elastomeres

- Variomould

- Co-injection

- Process Combinations

Preventive Service

We offer many services for WITTMANN BATTENFELD injection molding machines to make sure your machine is running at its full potential and efficiency.

Calibration Service

This tool includes setting and readjustment of parameters (strokes, velocities, pressures and temperatures) and effects optimum performance of the machine.

Direct user benefits:

- Precise repeatability of basic machine parameters (s-v-p-t)

- More precise repeatability in all processes

- Significant savings in time, energy and material

Preventive Service Package

This package includes the calibration service together with numerous additional service tools, to minimize maintenance costs and increase productivity.

- Machine inspection according to check list

- Visual check of wear & tear parts according to check list

- Analysis of hydraulic oil

- Free use of hotline service and web service included

- Exact scheduling of maintenance intervals by WITTMANN BATTENFELD

Energy Check

This check leads to a reduction of energy costs and a sustainable assurance of the productivity.

- Measurement of actual energy consumption

- Inspection of all parameters in order to secure optimal energy effieciency

- Possibilities to capitalize on the energy saving potential

- Final analysis and display of the achieved energy consumption minimization

Advantatages of preventive service

- Continuous technical OEM back-up

- Precisely calculable maintenance costs

- Extension of warranty period

- Exact calculation of maintenance requirements for hydraulic oil possible due to regular oil analyses

- Calculable repair - and exchange costs for wear & tear parts

- Minimization of machine wear

- Higher machine resale value

Control unit - upgrades

WITTMANN BATTENFELD machines are often used for several decades, and even after intensive use are still in good mechanical condition. Regardless of their current control system generation Typically these machines can be retrofitted with latest control technology when it is cost effective alternative to complete machine replacement.

Advantages

- Increased in reliability and uptime with the latest Unilog B8 control system and microprocessor technology

- Increased in productivity through reduction of downtime and shorter processing cycles for complex parts

- Smooth operation with latest technology

- Proven higher repeatability of processes by using latest control technology

- Preparation of individual process programs on site by the customer

- Integrated networking for data upload and download

- More efficient process documentation and monitoring

- E-mail function for automatic signaling of production stops

- Machine monitoring from the home office via the Internet

- Online provision of stored PDF files

Downloads