Expert systems

Expert systems

WITTMANN BATTENFELD Smart Machine

The intelligent clamping unit

Process monitoring is based on recording stroke-related measurement integrals per injection cycle with up to 400 measuring points. Each integrated measured parameter can be monitored within adjustable limit values.

- More functionality in process control and consequently more productivity

- Extension of the process window

- Improved component quality (through venting)

- Customized mold movement

- Less mold wear

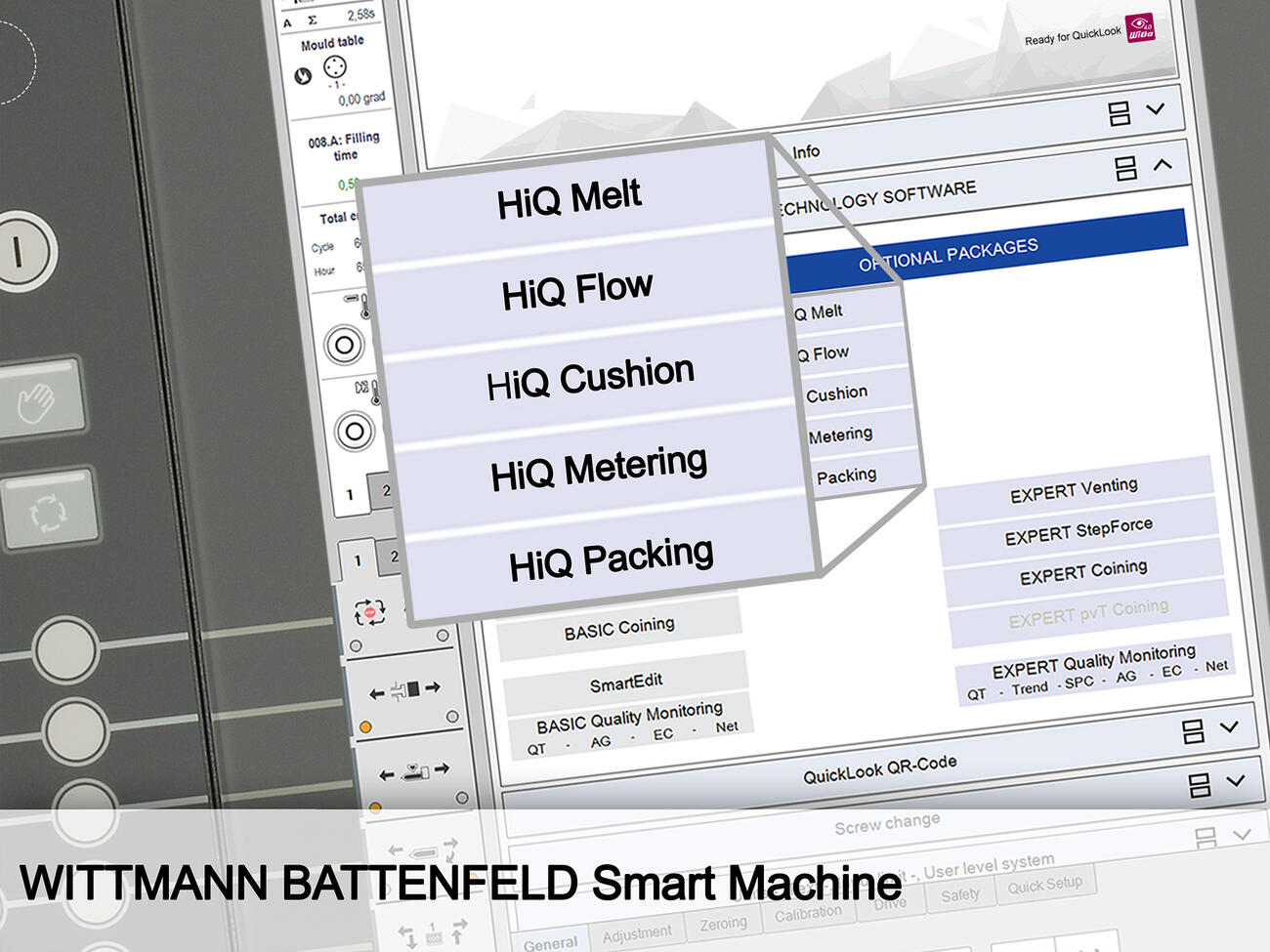

EXPERT packages

- Expert coining (for EcoPower)

High-precision coining and mold opening with the servo-electric clamping unit

- Expert coining (for MacroPower)

High-precision coining and mold opening including parallelism control and simultaneous operation of all four tie-bar pressure pads

- Expert pvT coining (for MicroPower, EcoPower)

Highly dynamic coining process based on the correlation between the specific volume and temperature of the plastic melt inside the mold

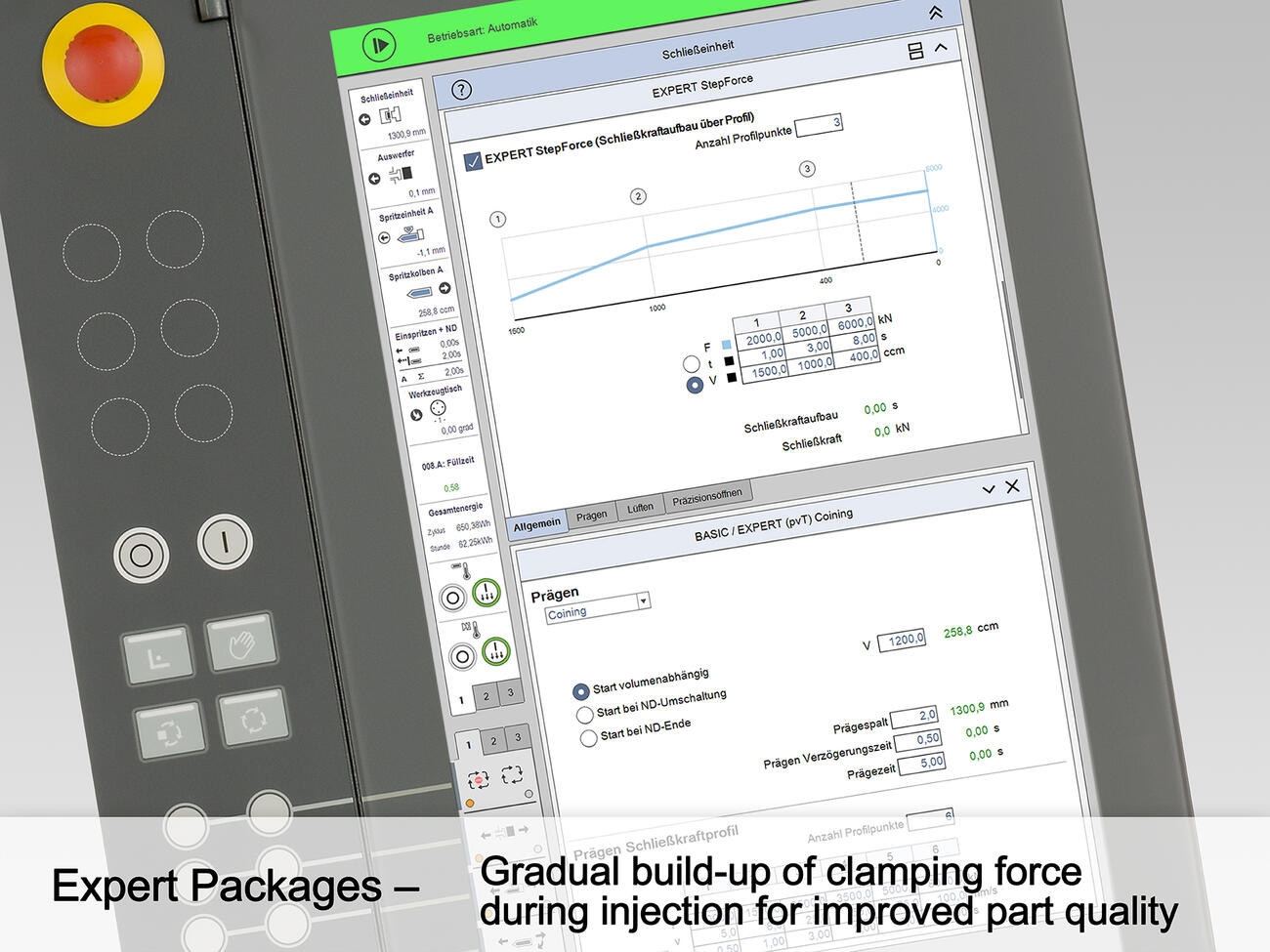

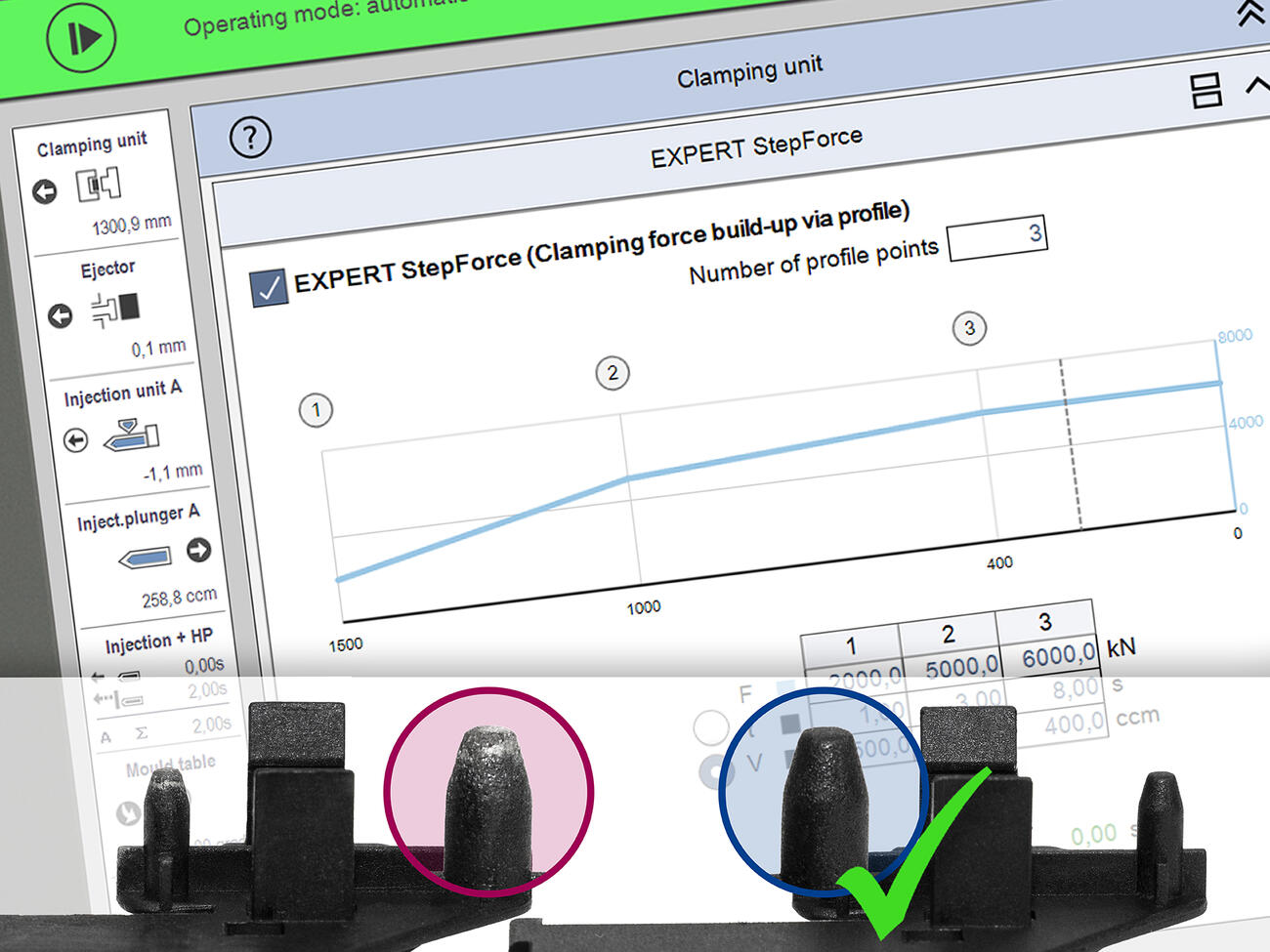

- Expert StepForce (for EcoPower, MicroPower, MacroPower, SmartPower)

Step-by-step clamping force build-up during injection, synchronized either via the injection volume or via the injection time. This facilitates venting via the mold parting line and thus cavity filling. An economic side effect is the resulting reduction in drive energy consumption.

- Expert venting

Mold opening for venting, for example in combination with thermoset processing

Downloads