Airmould – Internal gas pressure technology

Airmould – Internal gas pressure technology

The patented gas-assisted injection molding process developed by WITTMANN BATTENFELD

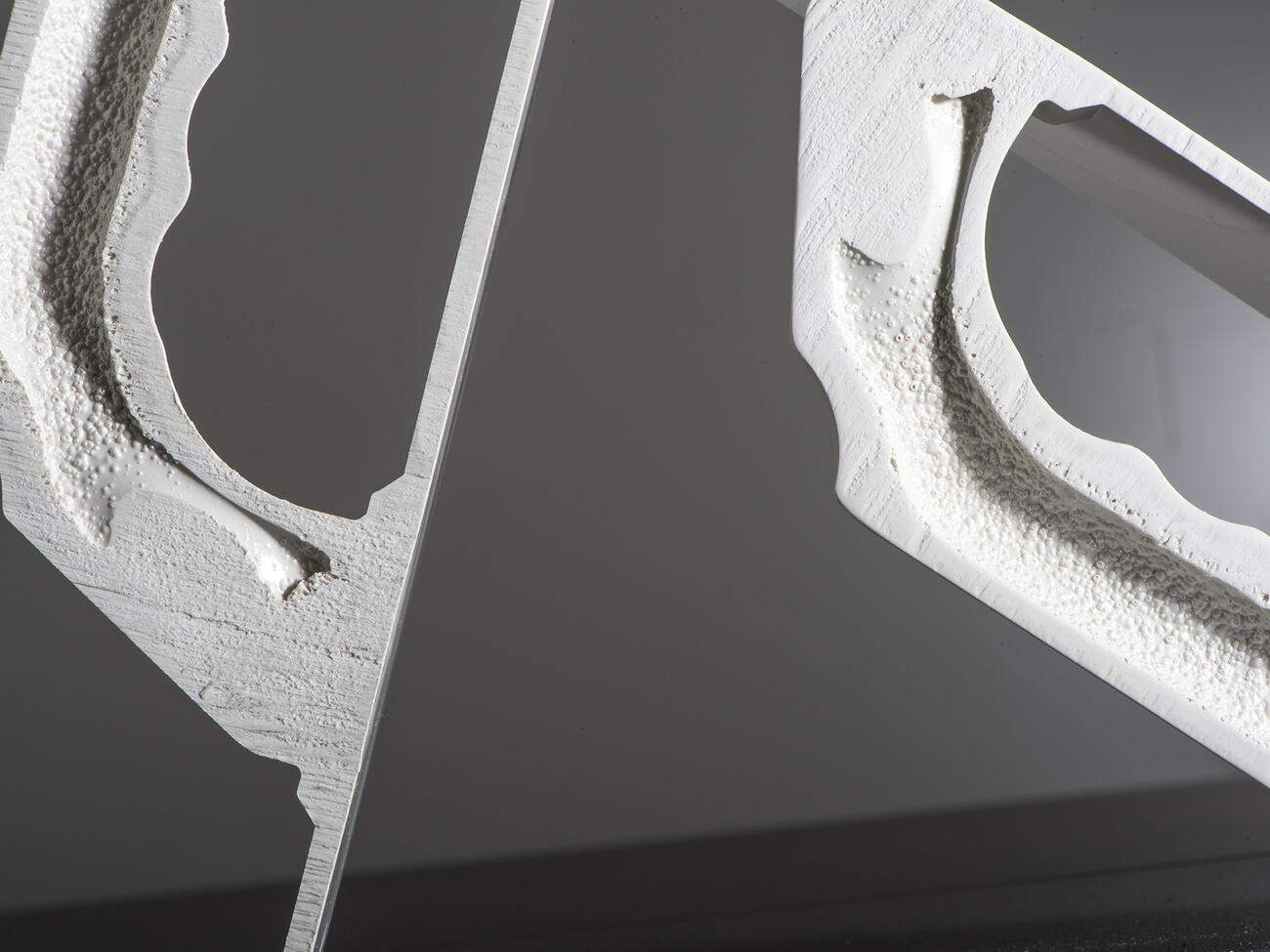

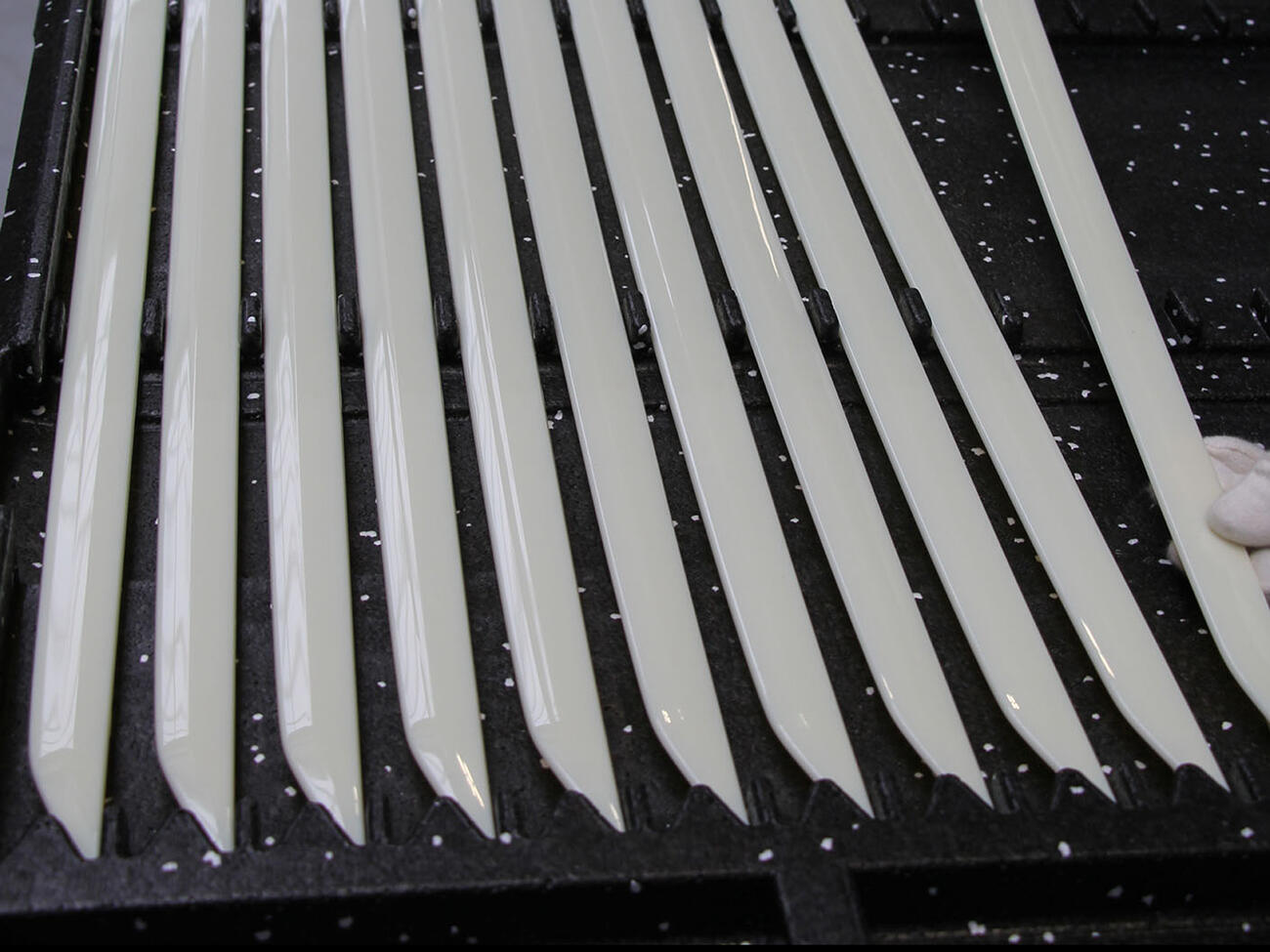

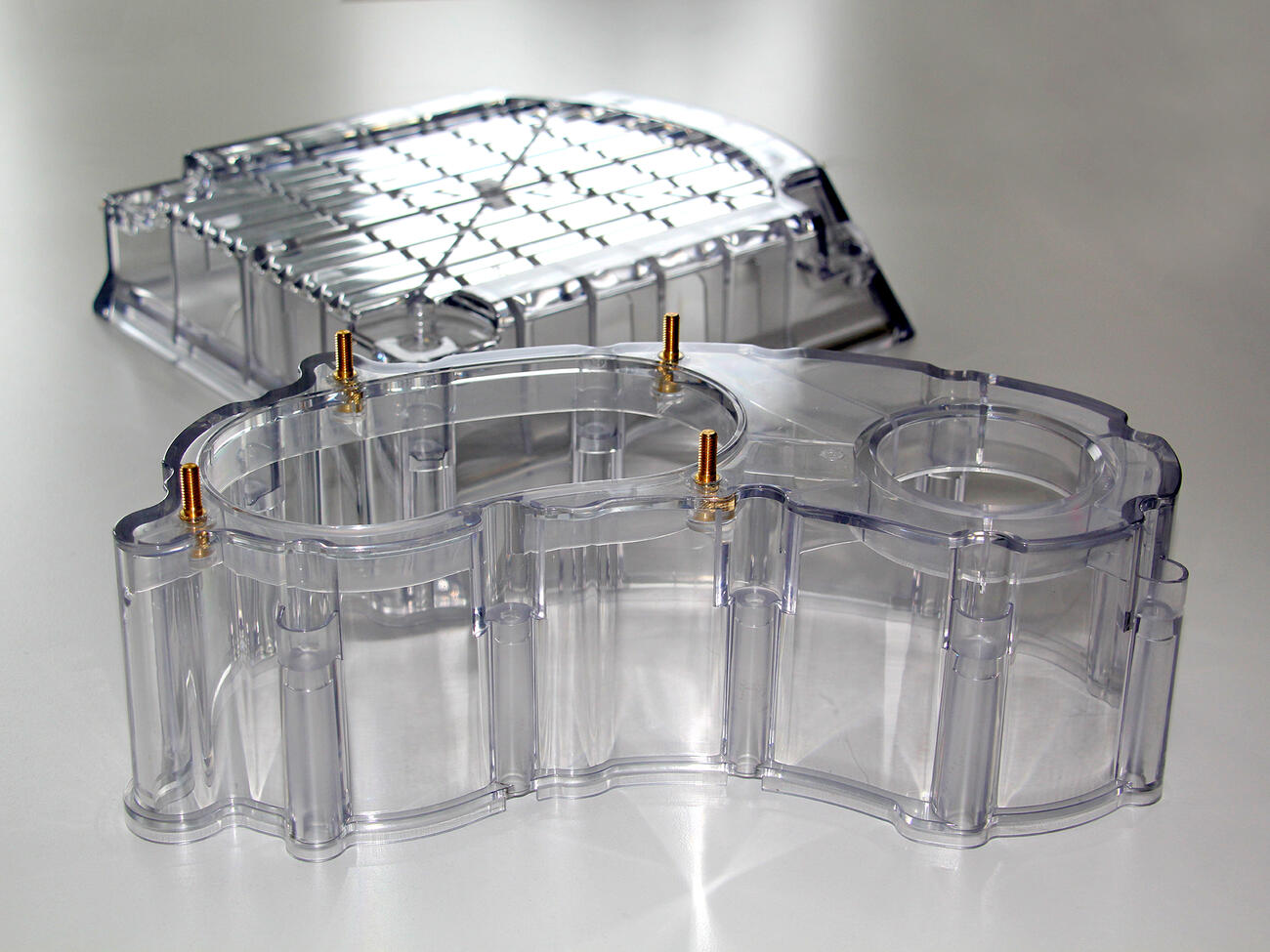

Airmould application

Airmould internal gas pressure injection molding is a process in which nitrogen is injected into the mold cavity partly or completely filled with melt. The pressurized gas forms a bubble at the center of the melt, which counteracts shrinkage contraction on the outside and thus eliminates sink marks. By reducing the amount of plastic and enlarging the central cavity, it is possible to produce specific lightweight components with short cycle times and simultaneously good surface quality. This process opens up good opportunities for molded part designers to produce complex parts with smooth surfaces in one piece.

Advantages of Airmould application:

- Quality improvement

- Weight reduction

- Plastic material savings

- Reduction of component unit costs

- Prevention of sink marks

- Reduction / prevention of warpage

- Design freedom

Airmould and Airmould 4.0 equipment

The nitrogen and pressure generation equipment developed and manufactured by WITTMANN BATTENFELD is available in different sizes and with varying capacities, to supply individual machines or to function as central systems supplying several machines.

The control systems of the units are self-explanatory. All important process information is clearly displayed. The control of every unit can be integrated into the corporate network, which enables transfer of all settings and visualizations within the plant to any network-compatible PC.

Machine equipment for Airmould and Airmould 4.0:

- Nitrogen generator (SE)

SE series, mobile units, store nitrogen filtered from the surrounding atmosphere through a multi-membrane system - Compressor (DE)

DE series, nitrogen is compressed to an operating pressure of 300 bar - Injection modules or Airmould machine nozzle

- Pressure control modules – programmable with handheld control unit as of model Airmould 4.0 or full integration into Unilog B8

Machine equipment for models up to 2020:

- Mobile control unit

- Monomodules – easy programming by means of a hand held programming device

Advantages of the equipment

- All components from a single source

- Can be expanded at any time by adding a nitrogen generator

- Independent operation, logistics to supply nitrogen bottles

- Modest space requirements

- Modern control system with remote control options

- Up to eight pressure control modules can be connected

- Program to control core pulls

Downloads

References