Cellmould – Light weight technology

Cellmould – Light weight technology

For the production of extremely light and highly rigid parts without sink marks

Cellmould application

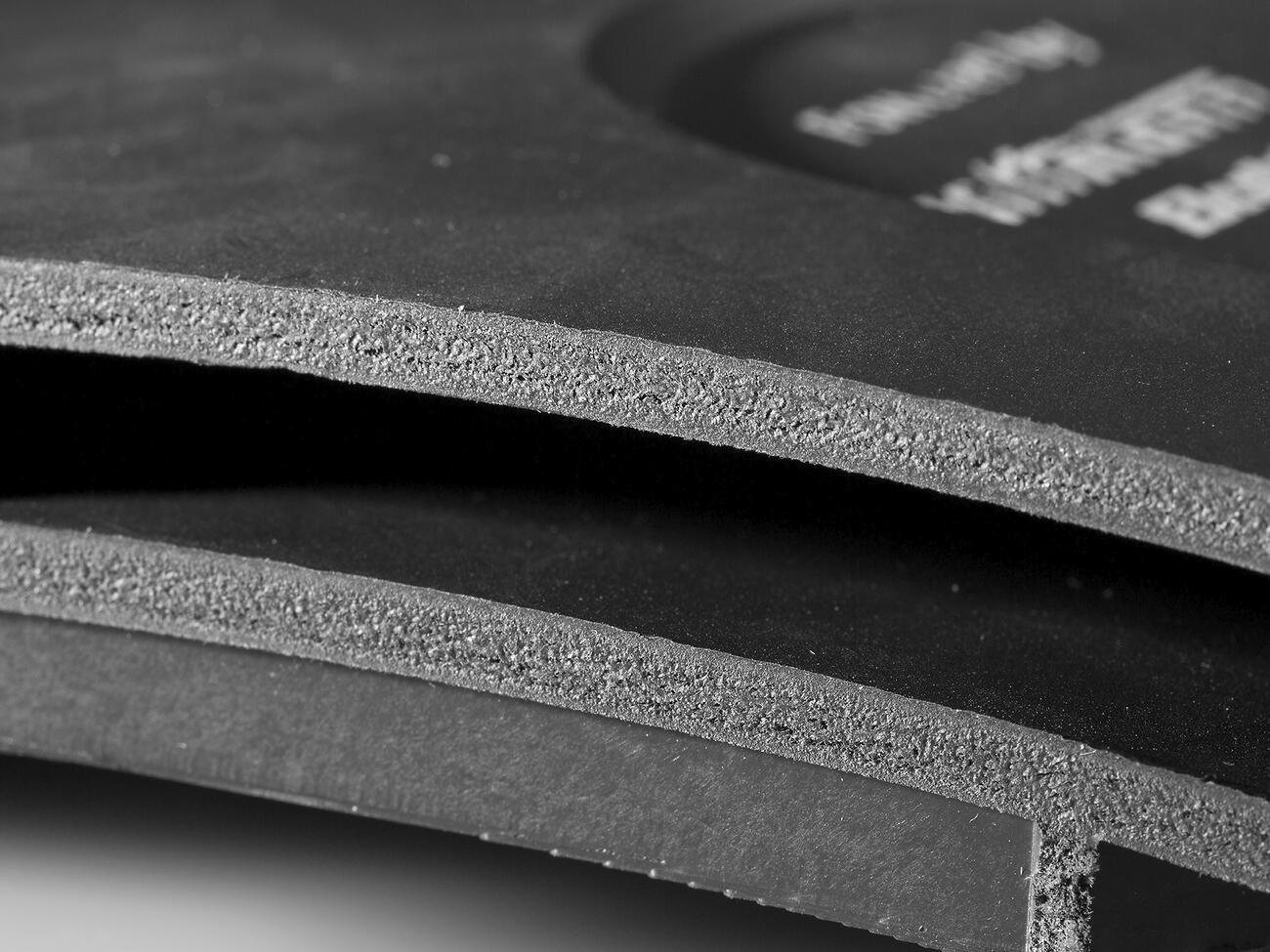

Either chemical or physical foaming agents are used in the production of structured foam parts. Chemical foaming agents are added to the plastics granulate in the form of master batches, powders or liquids. Gases or liquids are used as physical foaming agents, which are injected into the barrel. The foaming agent used in the Cellmould process is nitrogen. This technology is ideally suited for manufacturing light, structured components.

Cellmould ligthweight technology enables the production of foamed, highly rigid parts without sink marks. The aim of the Cellmould lightweight technology is to produce both thick-walled and thin-walled structural foam parts with a fine and even foam structure with reduced weight.

Advantages of the Cellmould application

- Weight reduction

- Plastic material savings

- Reduced component costs

- Prevention of sink marks

- Reduction of warpage

- Narrower tolerances

- Higher rigidity with the same weight

- Longer maximum flow paths due to reduced viscosity

- New scope for design

- Reduction of cycle time

- Lower clamping forces

Cellmould equipment

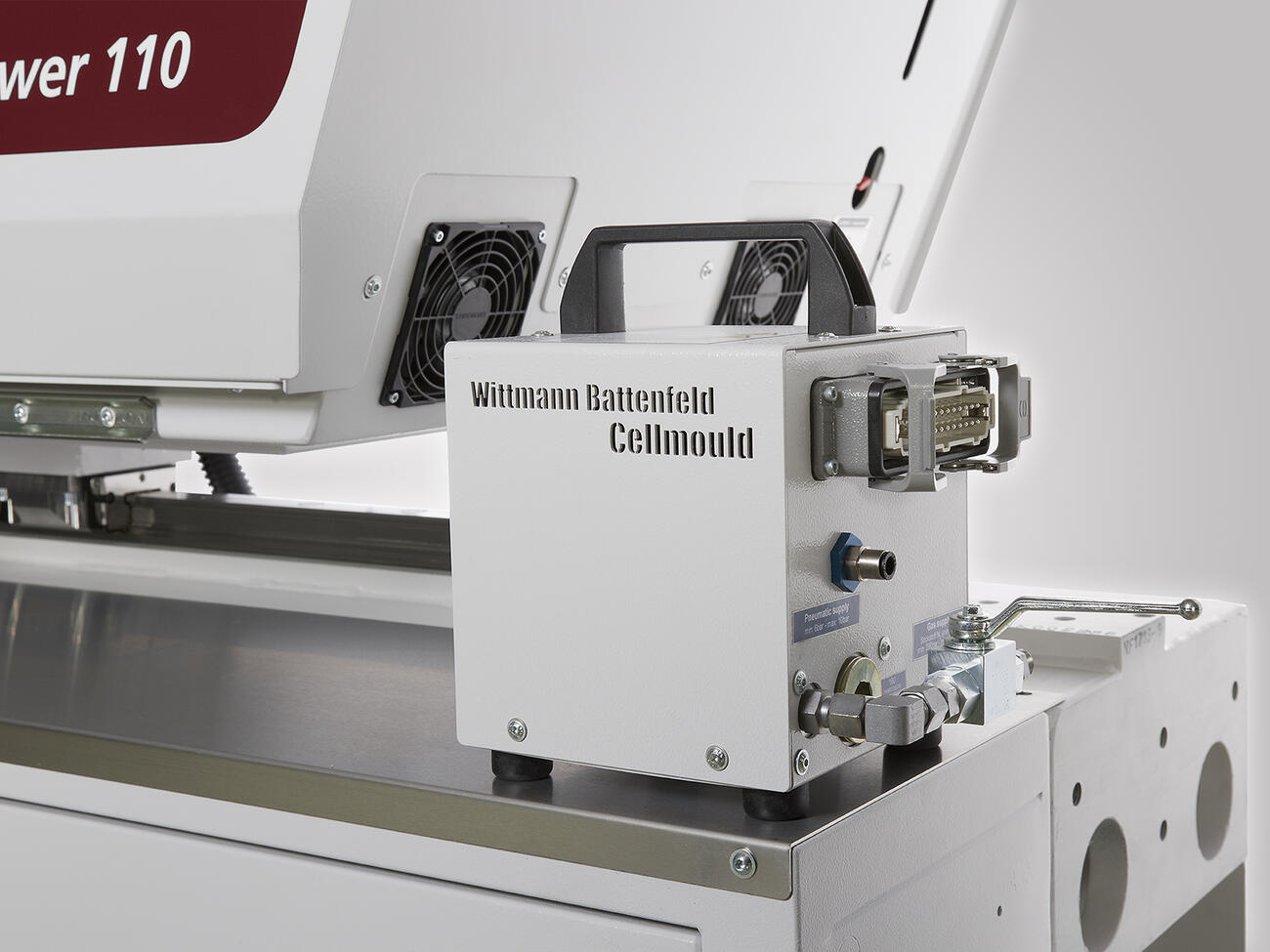

The entire Cellmould technology has been developed by WITTMANN BATTENFELD, and all of its components are produced in-house. Thus, WITTMANN BATTENFELD is the only injection molding machine manufacturer able to supply both the machine and the equipment for physical foaming according to the motto “One-Stop-Shop”.

Machine equipment:

- Special screw and barrel unit with 25 L/D for Cellmould

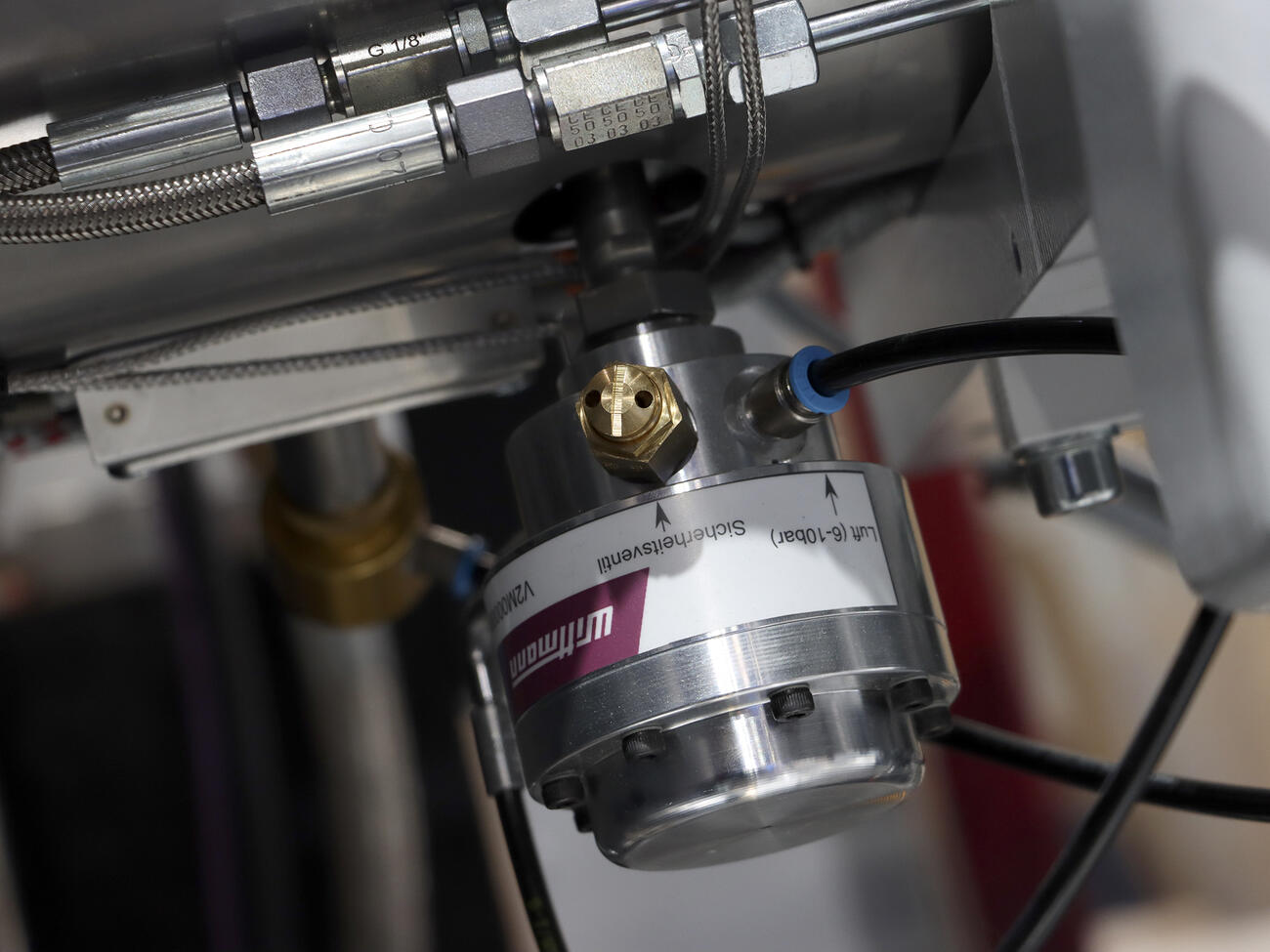

- Injector for gas injection directly into the barrel

- Gas flow regulator module to ensure precisely controlled gas injection

- Needle shut-off nozzle to prevent leakage of melt which contains foaming agent

- Control and regulation of the Cellmould process via the Unilog B8 control system

- Nitrogen generator and compressor unit as with the internal gas pressure process AIirmould

Advantages of the equipment

- Can be expanded at any time by adding another nitrogen generator

- Modern control system with remote control options

- Modest space requirement

- Compact, soundproof equipment

- Independent operation

- Nitrogen purity min. 98%

- One control system for the entire system

Downloads

References