Investing in seminal technology

Investing in seminal technology

Werkzeugbau Winkelmühle GmbH, Germany

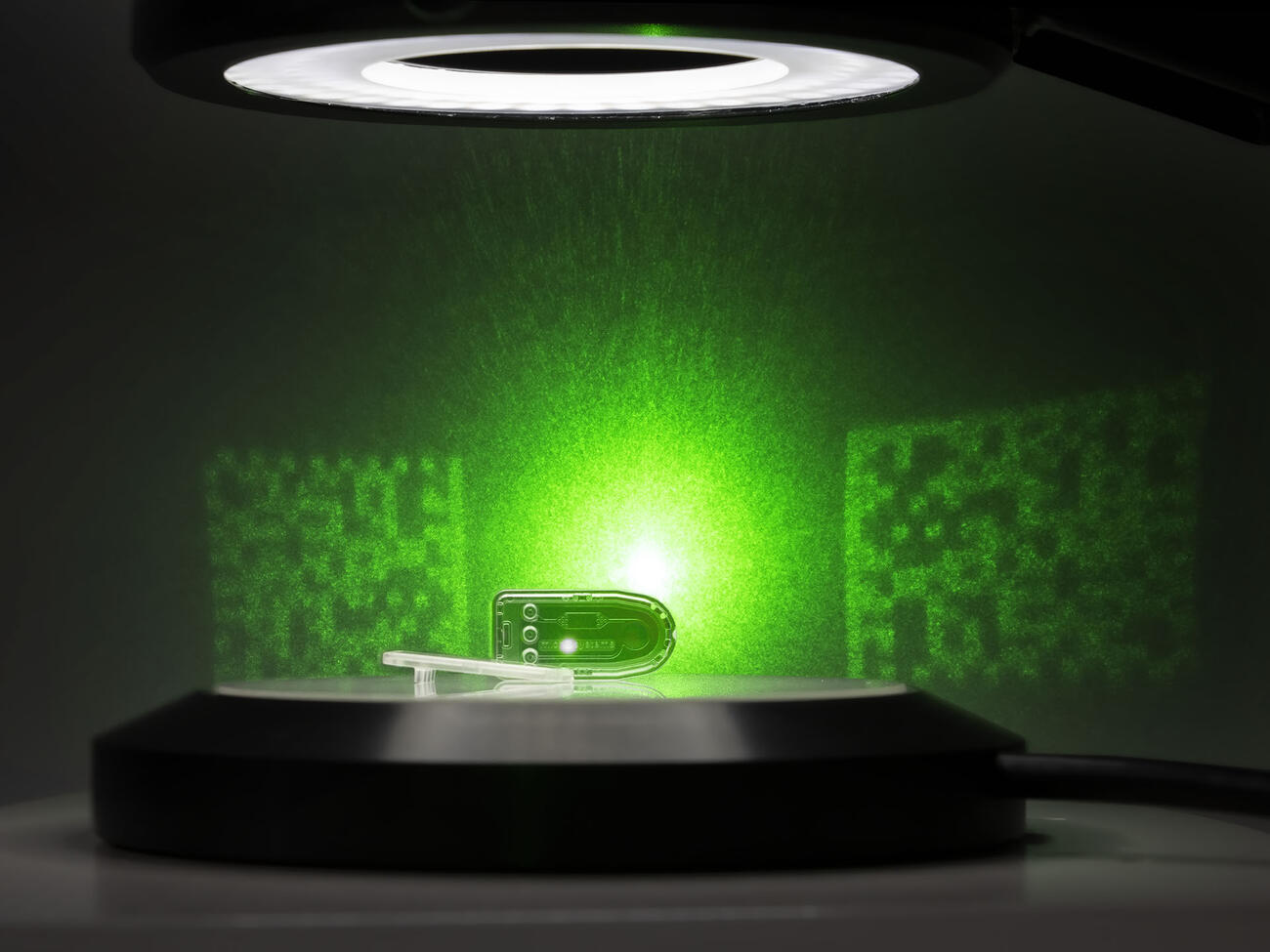

Werkzeugbau Winkelmühle, domiciled in Klingenberg / Saxony, Germany plans to position itself more broadly on the market and has therefore acquired 2-component technology from WITTMANN BATTENFELD to extend its service portfolio.

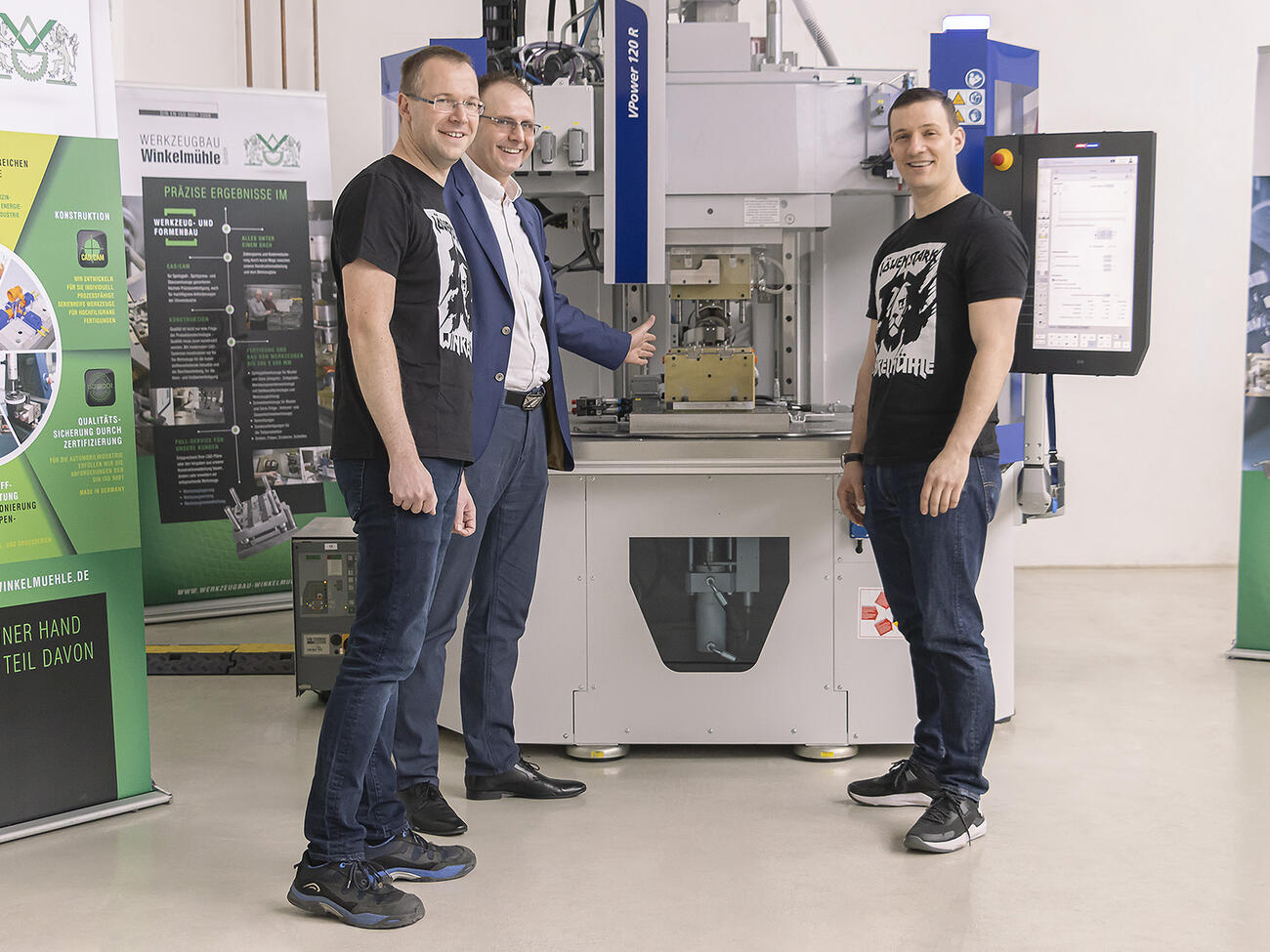

Werkzeugbau Winkelmühle, which emerged in1992 from its predecessor company “Elektronische Bauelemente Dorfhain”, is a family-owned and owner-managed enterprise in the second generation. The company’s founders, Karl-Heinz Berthold and Hartmut Baumgart, are still supporting its present Managing Director Tom Berthold in an advisory capacity. With a workforce of more than 70 employees, Werkzeugbau Winkelmühle manufactures at its location in Klingenberg high-precision punching and injection molding tools, as well as parts in the area of punching and plastics technology for use in electronic systems. The latter are mostly metal-plastic combinations and micro parts. The products are used primarily in interiors and engine compartments of motor vehicles. But components are also being produced for the watchmaking, solar and furniture industries, as well as for the energy sector and optical transmission systems. The majority of the company’s customers are based in the Saxony region.

Werkzeugbau Winkelmühle scores among its customers above all with the high-quality standard of its products, its flexibility and reliability as well as the know-how from its many years of experience. The majority of its injection molded products are highly complex, sophisticated parts, which are required to meet high standards of precision and load capacity. Especially in the automotive sector, the components are often exposed to extreme environmental conditions.

In its injection molding department, Werkzeugbau Winkelmühle is currently operating 24 machines, more than half of which have come from WITTMANN BATTENFELD, including two micro injection molding machines and four vertical machines.

“The machines from WITTMANN BATTENFELD fulfil the criteria we require in every respect. What is more, they come with a compact design and are extremely energy-efficient.”

Eric Mende, Werkzeugbau Winkelmühle GmbH

Downloads