MicroPower – medical technology solution

MicroPower – medical technology solution

Precise, Efficient and Clean

Micro Systems UK Ltd.

Versatile and flexible

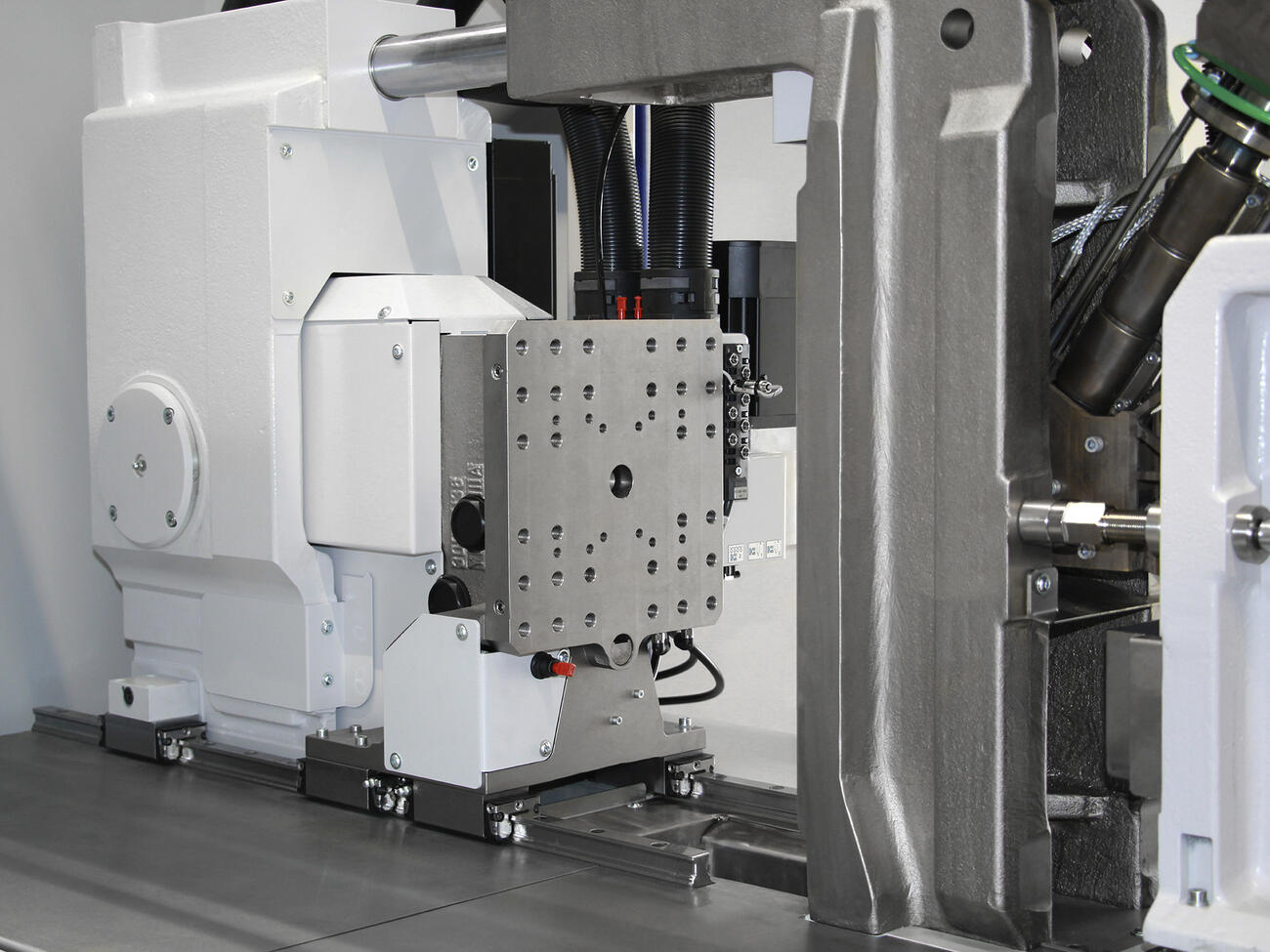

In order to meet the diverse requirements in medical technology and to fulfil the general conditions in terms of process technology and machine technology, the MicroPower series basic concept was already made to be prepared for these expectations.

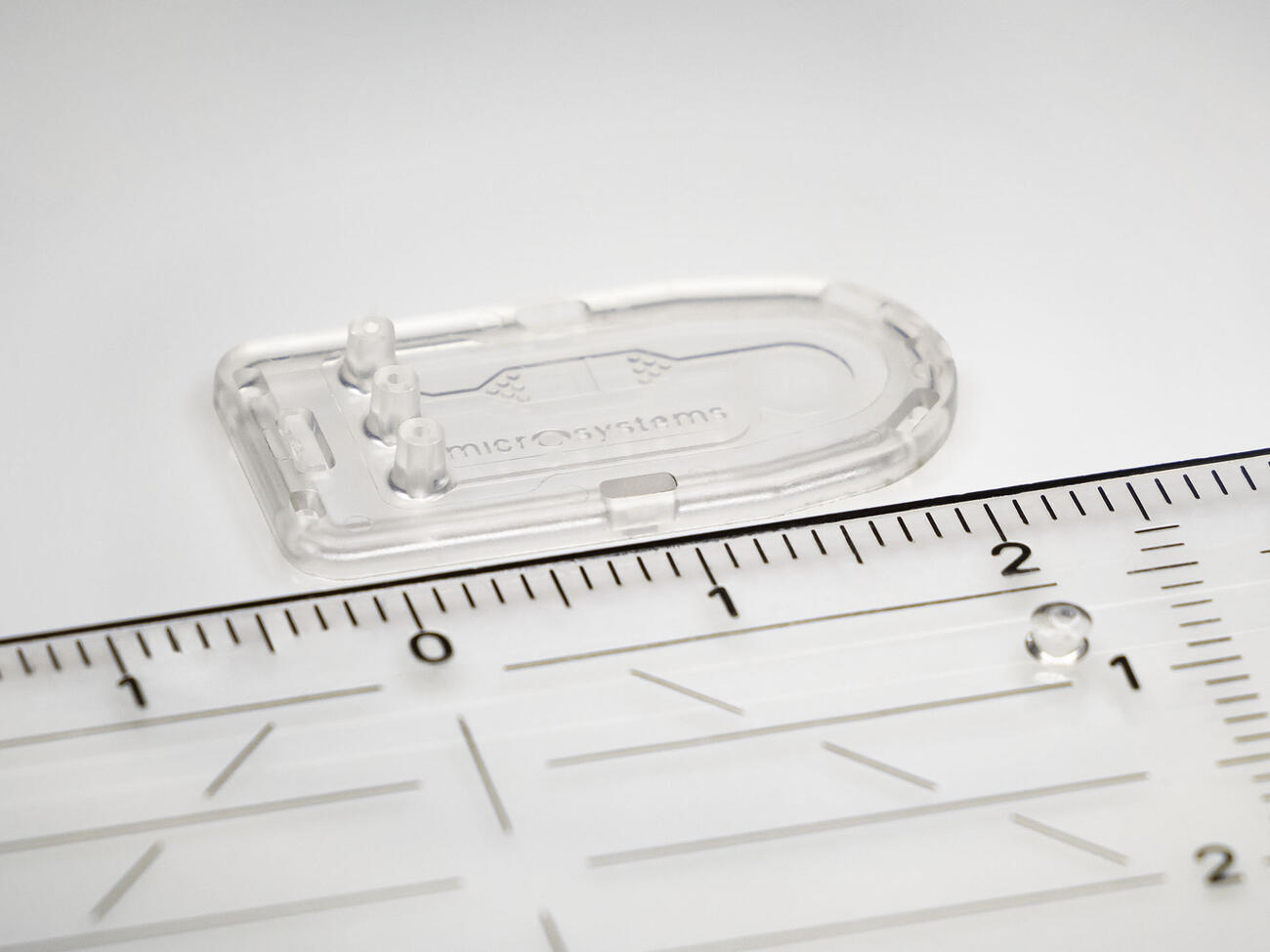

This is demonstrated on two connected MicroPower 15/10 machines that produce a so called "Lab-on-a-chip" (LOC). The LOC designates a microfluidic system that reduces the different functions of a conventional blood laboratory to the size of a microchip using the smallest amounts of liquid.

With this "lab-on-a-chip technology", liquids, including blood, can be analysed completely on a single chip.

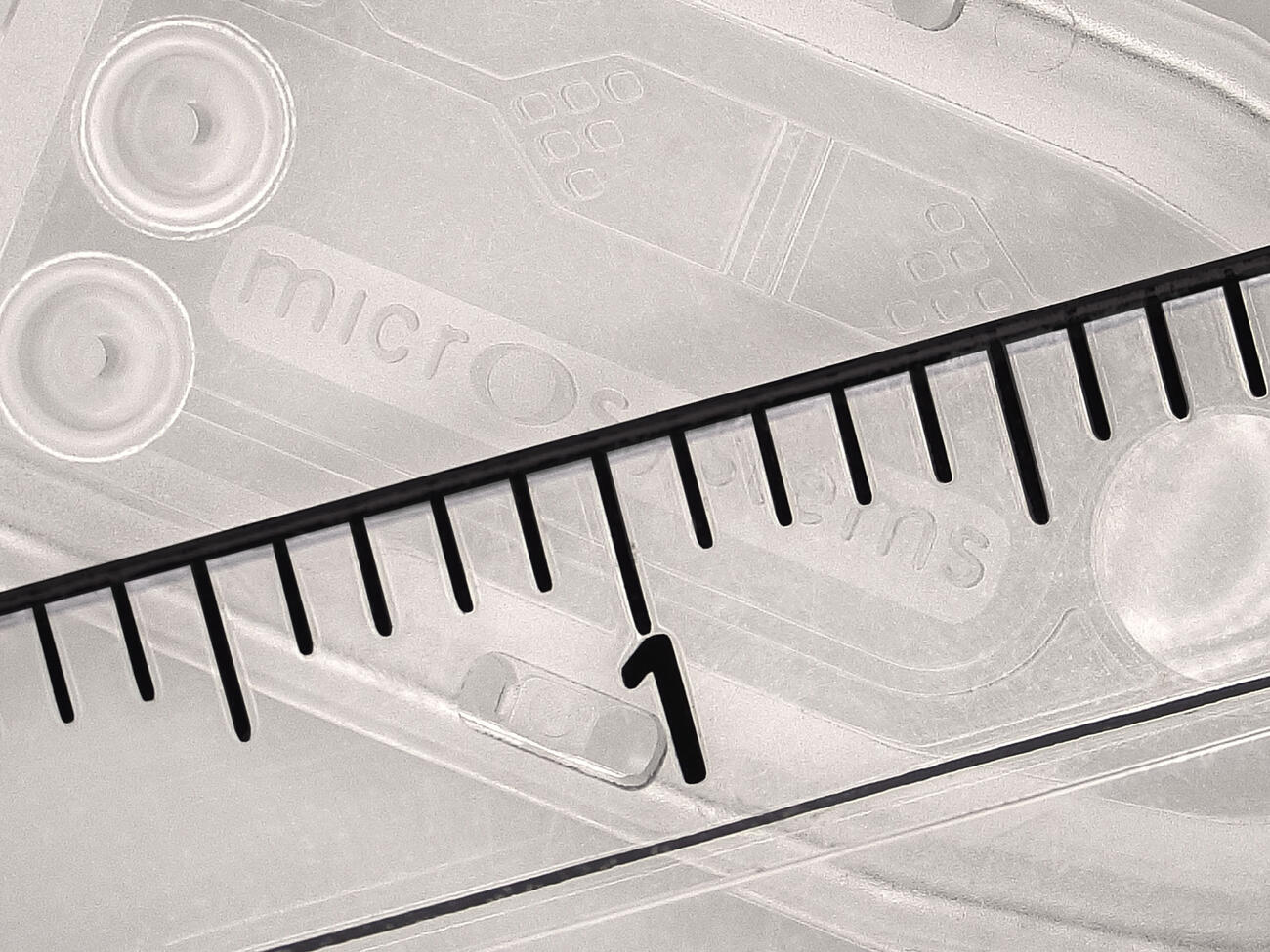

From a technological point of view, "lab-on-a-chip" systems can be considered as a subcategory of micro-electromechanical systems, which combine miniaturized sensor systems and microfluidics. This poses special challenges to surface structuring and surface coating. The transport of the liquid samples between the different reaction and analysis chambers primarily takes place through so called capillary forces. To produce such kind of parts, it’s necessary to pay special attention on the micro structured surface.

During the production process, the base parts of the so called “credit card laboratory” are molded, quality checked and automatically assembled in the upstream MicroPower. The part is then transferred to the downstream MicroPower 15/10 via a linear axis. A combi - insertion/removal gripper picks up the component and places it in the tool, where the handle and the component seal are finally overmolded. After completion, the Scara robot W8VS2 takes over the component and after the final visual quality check, the part will be dropped in the good part deposit station. The tools are made by Micro Systems UK.

A very important point in medical technology is the complete recording of process data as well as the general data management for the manufactured product. With the help of the Wittmann 4.0 full integration, all auxiliaries are managed in the Unilog B8 machine control and all necessary setting parameters are clearly assigned to the respective machine. This means that errors can be ruled out and complete data recording can be guaranteed.

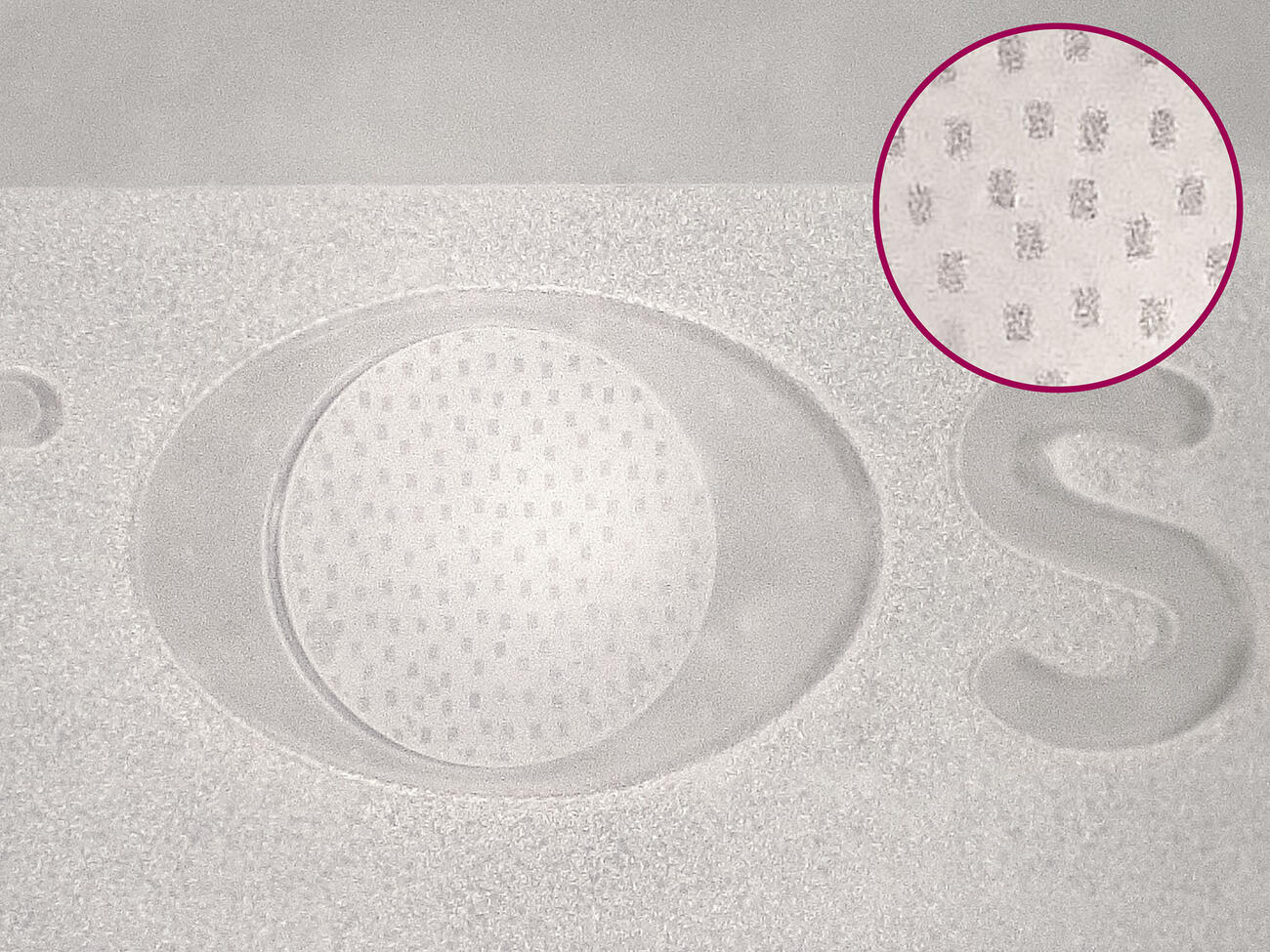

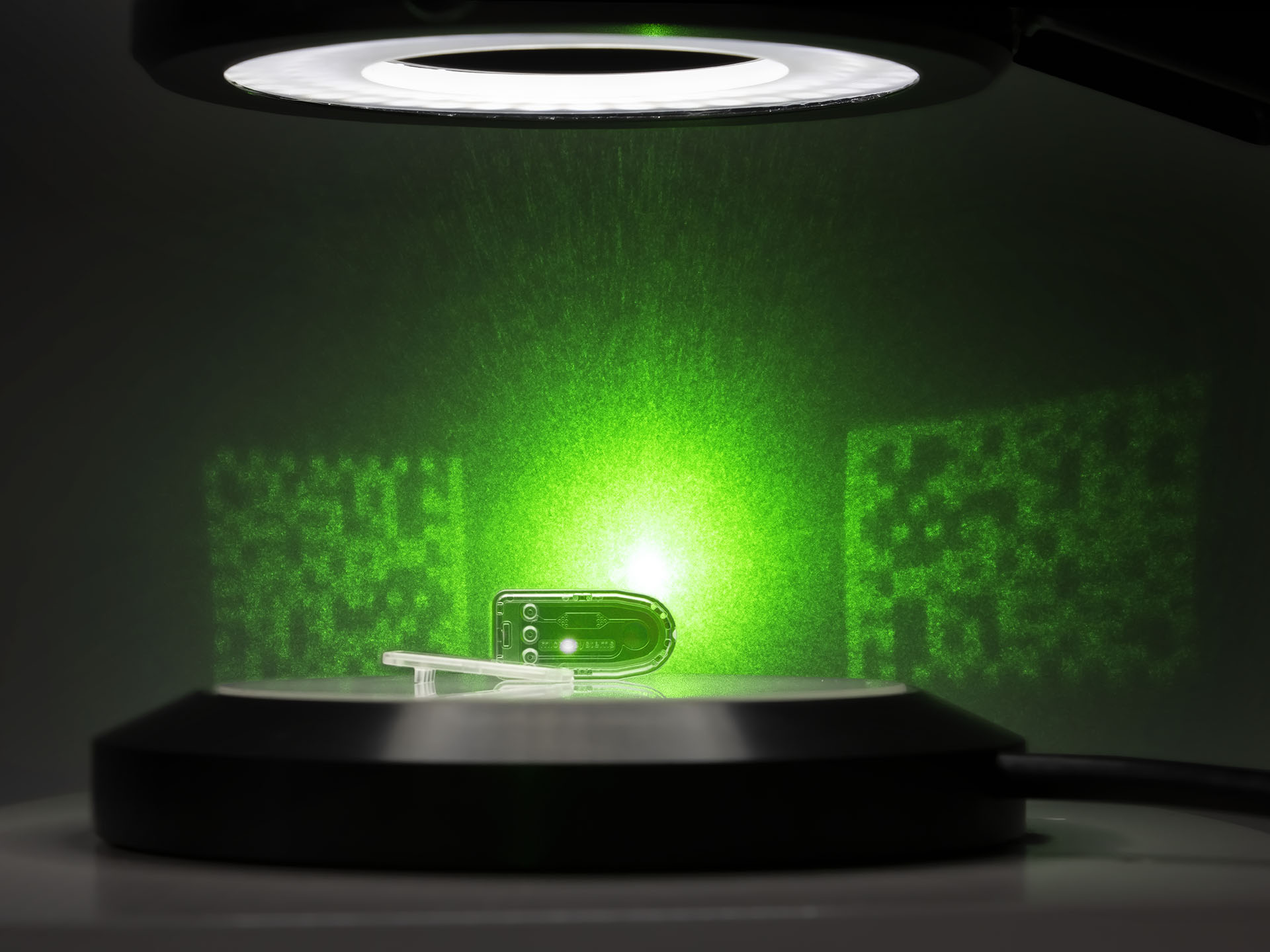

Another special feature of this product is the "invisible" copy protection, which is achieved by a 300 nm "small" surface structure which is injected together with the part. When this nano-structured surface of the transparent component is exposed to a beam of laser light, a hologram becomes visible to the human eye. This projected image can range from letterings, pictograms, images to QR codes.

'Due to the flexible design of the MicroPower production cell, it is easy to link several machines or automation systems together.

A small footprint paired with maximum flexibility and highest precision turns the MicroPower into a very important tool for efficient micro and small parts production – especially for medical technology.'

DI(FH) Martin Philipp-Pichler, Micro Injection Molding Project Engineer at WITTMANN BATTENFELD