Saving space and energy

Saving space and energy

MESTO Spritzenfabrik Ernst Stockburger GmbH, Germany

The sprayer manufacturer MESTO based in Freiberg / Neckar relies on injection molding machines from the WITTMANN Group to modernize its machinery. Apart from reliability and quality of service, the most attractive features of WITTMANN BATTENFELD machines are their low energy consumption and compactness.

MESTO, a family-owned company in the third generation, was established in1919 by Karl and Ernst Stockburger as a metal workshop. Its initial business consisted of repairs and locksmith work. In 1925, it started its production of spraying equipment. Today, the company with a workforce of 120 employees ranks among the leading manufacturers worldwide in the spraying equipment sector, making one million sprayers annually on 9,000 m² of production floor.

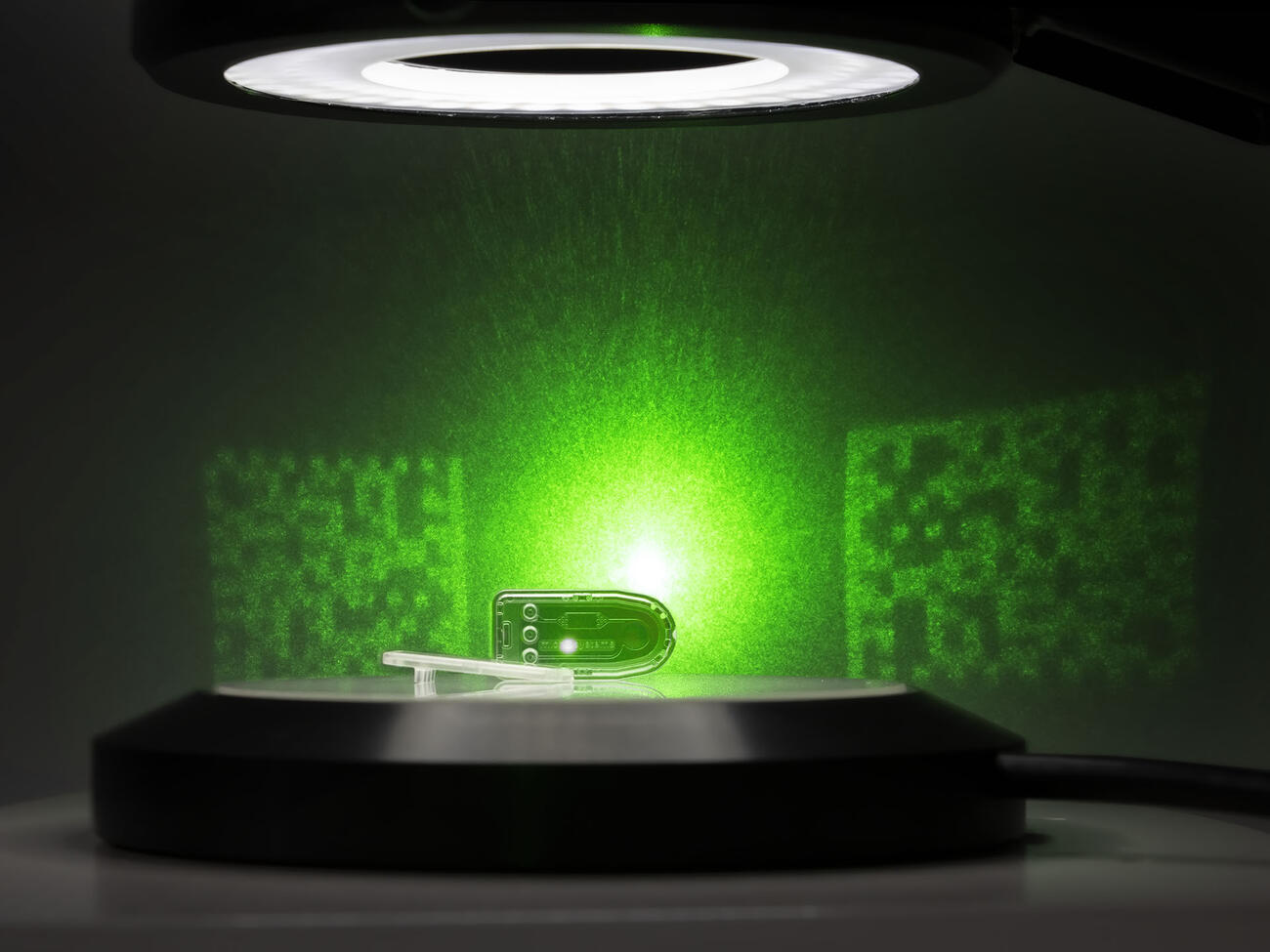

In the 1970s, MESTO started the production of plastic parts for its appliances, which was further extended with the construction of a new production hall in 2012. Its high vertical range of manufacture is one of the company’s vital success factors. Plastics injection molding, metalworking and assembly are all located in-house, to enable the production of steel and stainless steel containers as well as all necessary plastic parts, including appliances completely made of plastic.

'...electricity consumption has been reduced by 30% since 2017 by exchanging eight of a total of 16 existing machines for new ones from WITTMANN BATTENFELD.'

Élise Sellmayr, MESTO Spritzenfabrik Ernst Stockburger GmbH

Downloads