Full control of the material

Full control of the material

Intelligent injection molding while saving costs with WITTMANN BATTENFELD HiQ technology

Compensation for external influences

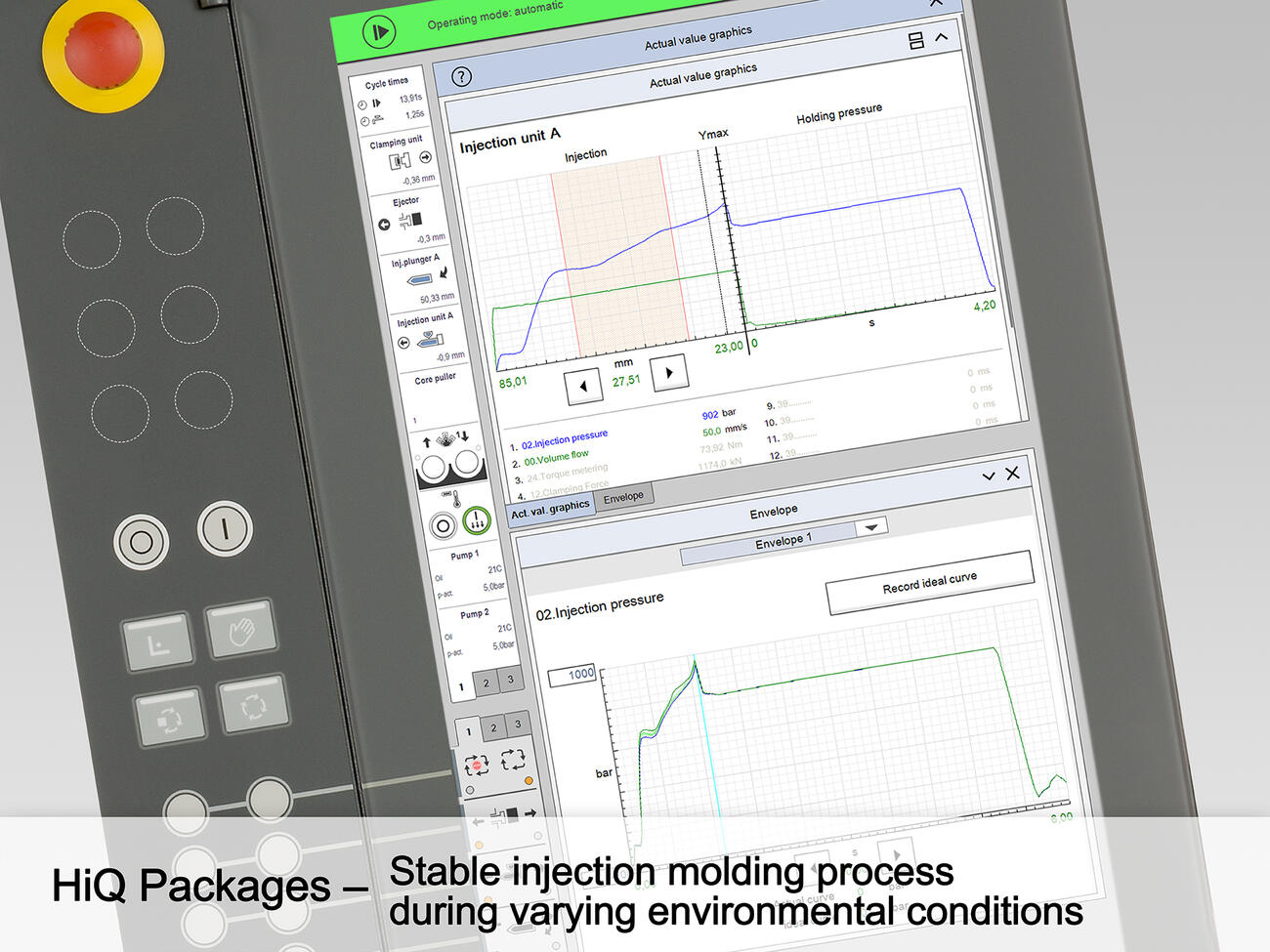

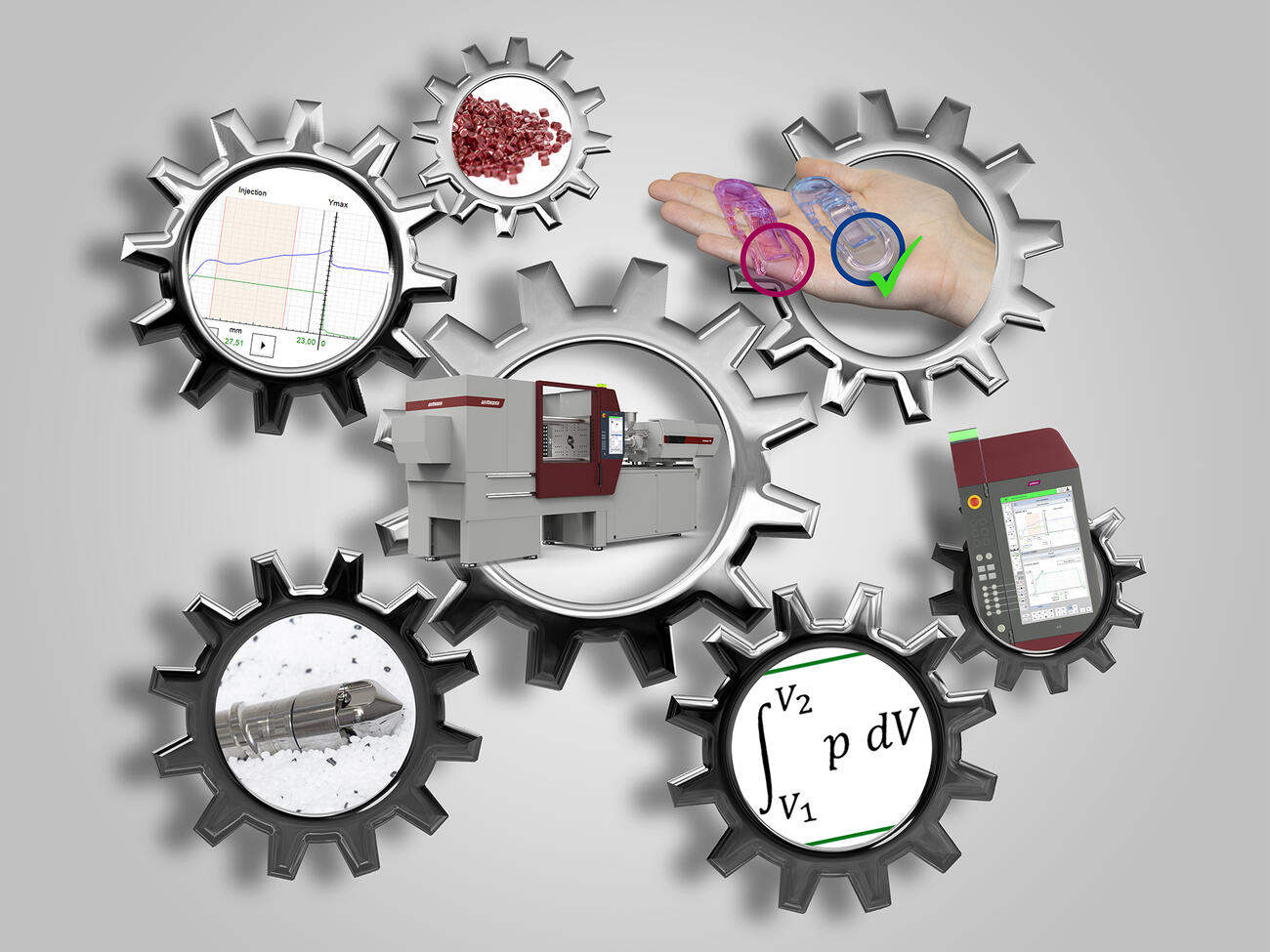

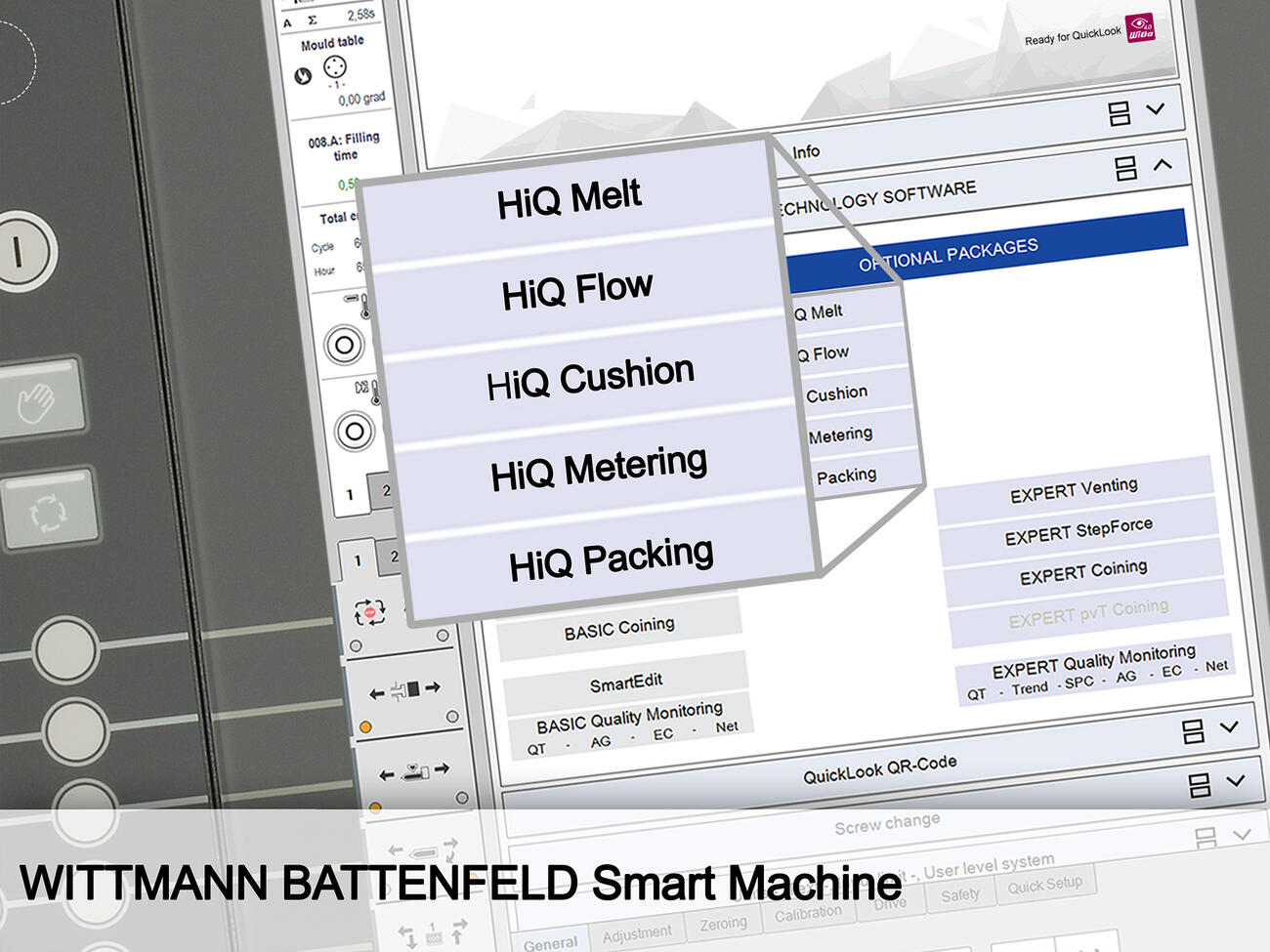

Viscosity fluctuations of the plastic melt and/or the closing behavior of the check valve have a considerable influence on the molding quality of the injection-molded part. This is precisely where WITTMANN BATTENFELD comes in with its application software, better known under the title of HiQ packages. These deal to varying degrees with monitoring, documentation and control of the injection molding machine.

The software packages, which have been available for a long time and have been continuously developed, are fully integrated into the machine control system. The underlying algorithms draw on the sensor signals from the injection molding machine at a sampling rate of up to 500 Hz in order to: detect irregularities, automatically counteract them during processing if necessary, or prevent deviations from occurring in the first place.

The HiQ packages offer numerous advantages to the economically conscious producer. With HiQ Metering, for example, the check valve can be actively closed. This feature has a positive effect on the reproducible molded part quality (assuming constant material viscosity). It is also possible to draw conclusions about the material viscosity independently of the mold. This is where HiQ Melt comes in: If unusual deviations are detected during metering, this can be intercepted by an automated and preventative reject operation. This supports consistent part quality or less re-selection of rejects. With HiQ Flow, consistent product quality can be achieved – and largely independent of material viscosity. This means that manual readjustment of the process parameters is no longer necessary. The result is fewer rejects and a faster startup process. All in all, material as well as personnel costs can be noticeably reduced by using HiQ Flow.

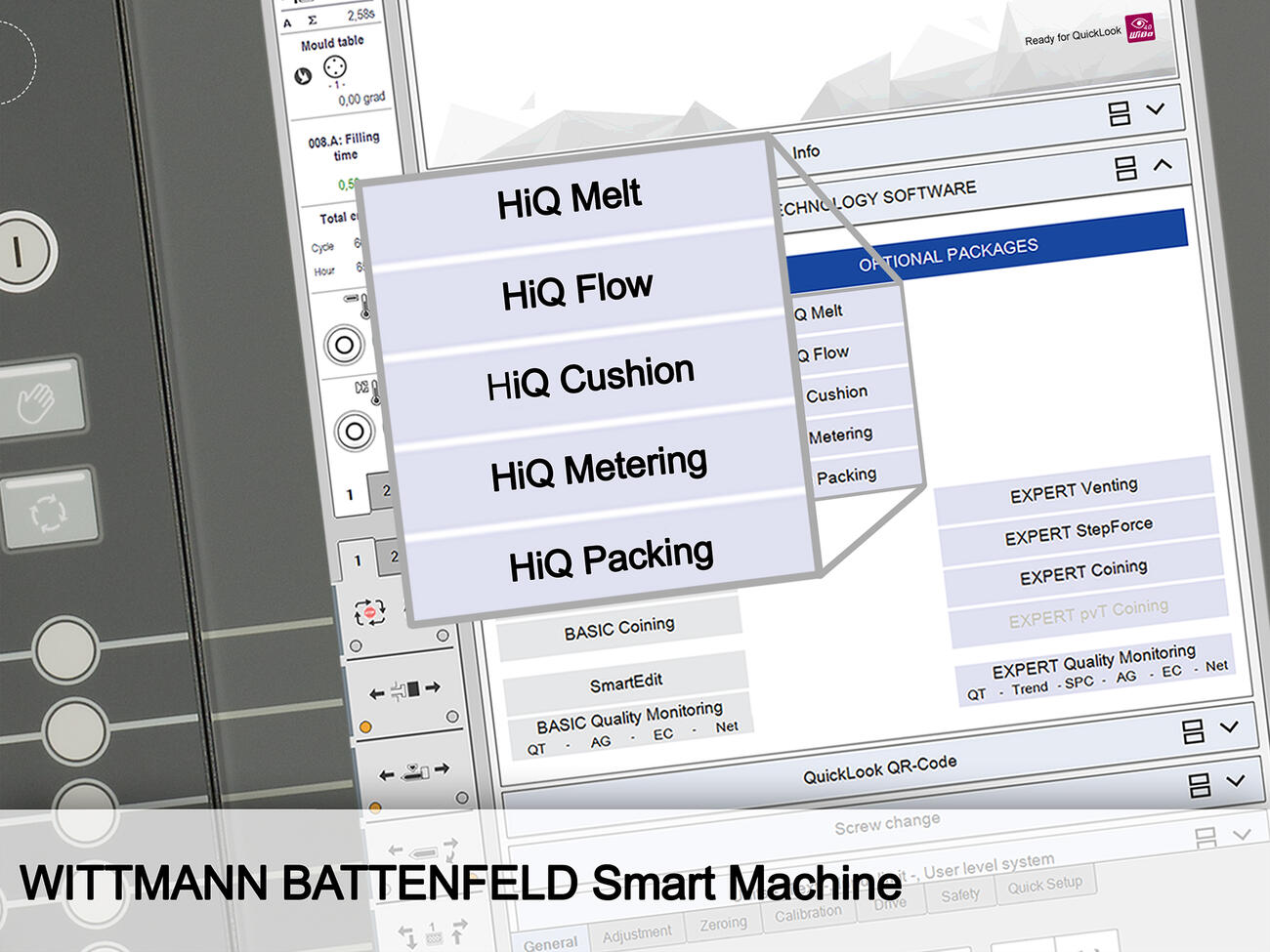

Customers can choose between the following packages:

- HiQ Metering

Active closing of the check valve after metering

- HiQ Melt

Mold-independent monitoring of the metering process

- HiQ Flow

Active control of changeover point and holding pressure level during each shot

'Using HiQ Flow®'s inline material data evaluation, the manufacturer no longer has to rely on lab results.

At the push of a button, the machine determines all the necessary parameters needed for the active control of the changeover point and holding pressure height.

This saves time, is recorded under real-life conditions and ensures that the entire process is highly flexible.'

Patrick Chromy, Head of Application Development at WITTMANN BATTENFELD

Downloads