Successful launch of the Airmould 4.0 technology

Successful launch of the Airmould 4.0 technology

The competitive system has been installed and tested on the premises of several customers

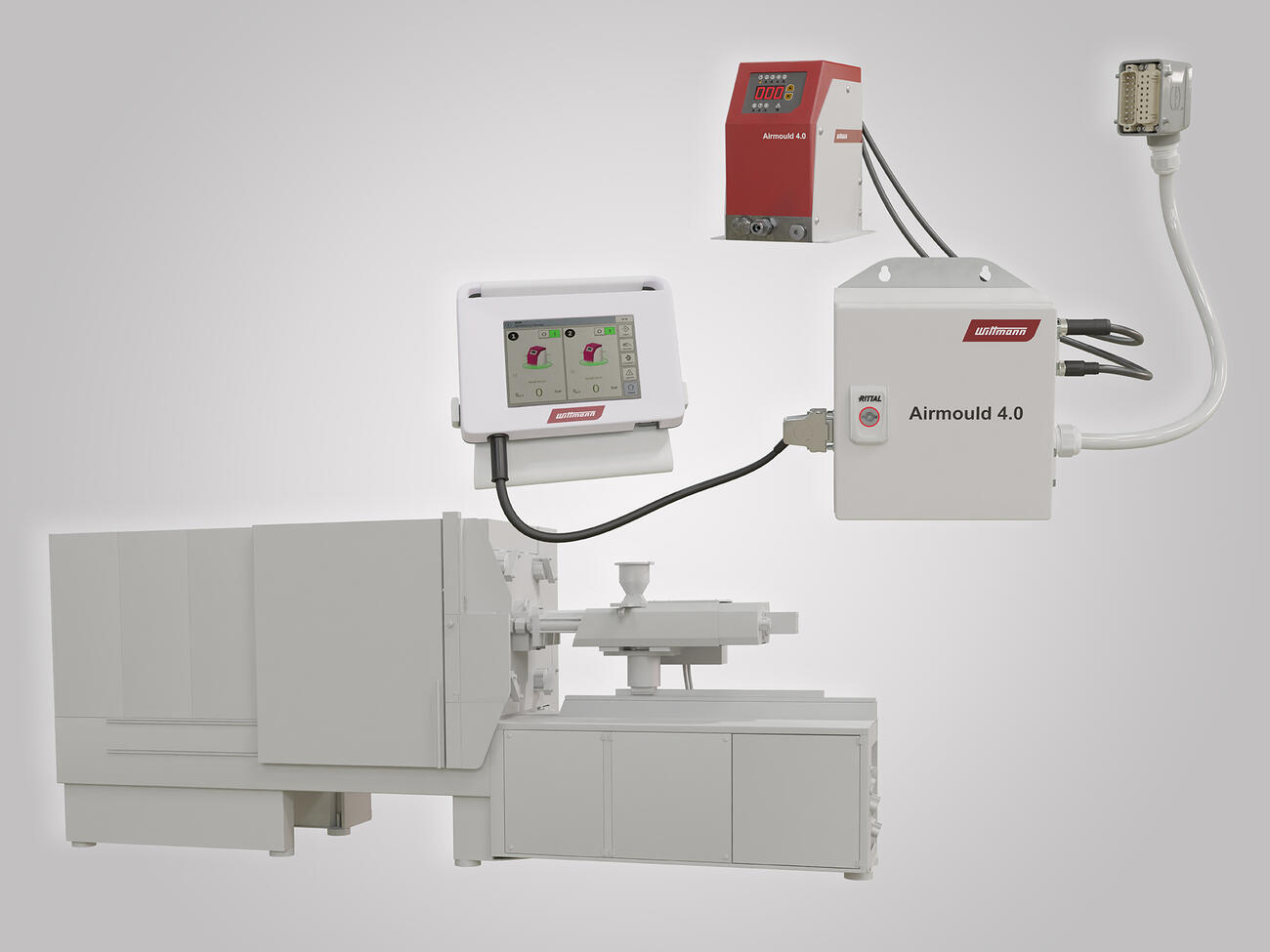

After WITTMANN BATTENFELD first presented the new generation of the Airmould internal gas pressure technology to its customers at the Fakuma 2021, the development targets have now been reached, and the competitive system has already been installed and tested on the premises of several customers. With the further development of Airmould, an even more compact and user-friendly system has been created, which meets the requirements of the industry and offers its users a number of advantages.

Airmould is WITTMANN BATTENFELD’s solution to meet the need for saving resources and for light-weight construction, and for extremely short cycle times as well. Airmould internal gas pressure technology is a process by which nitrogen is injected into a mold cavity either partly or completely filled with plastic melt to form an internal cavity structure. In this way, lightweight parts can be produced within a short cycle time and with high-quality surfaces, while also saving resources.

Downloads