LSR processing in micro injection molding

LSR processing in micro injection molding

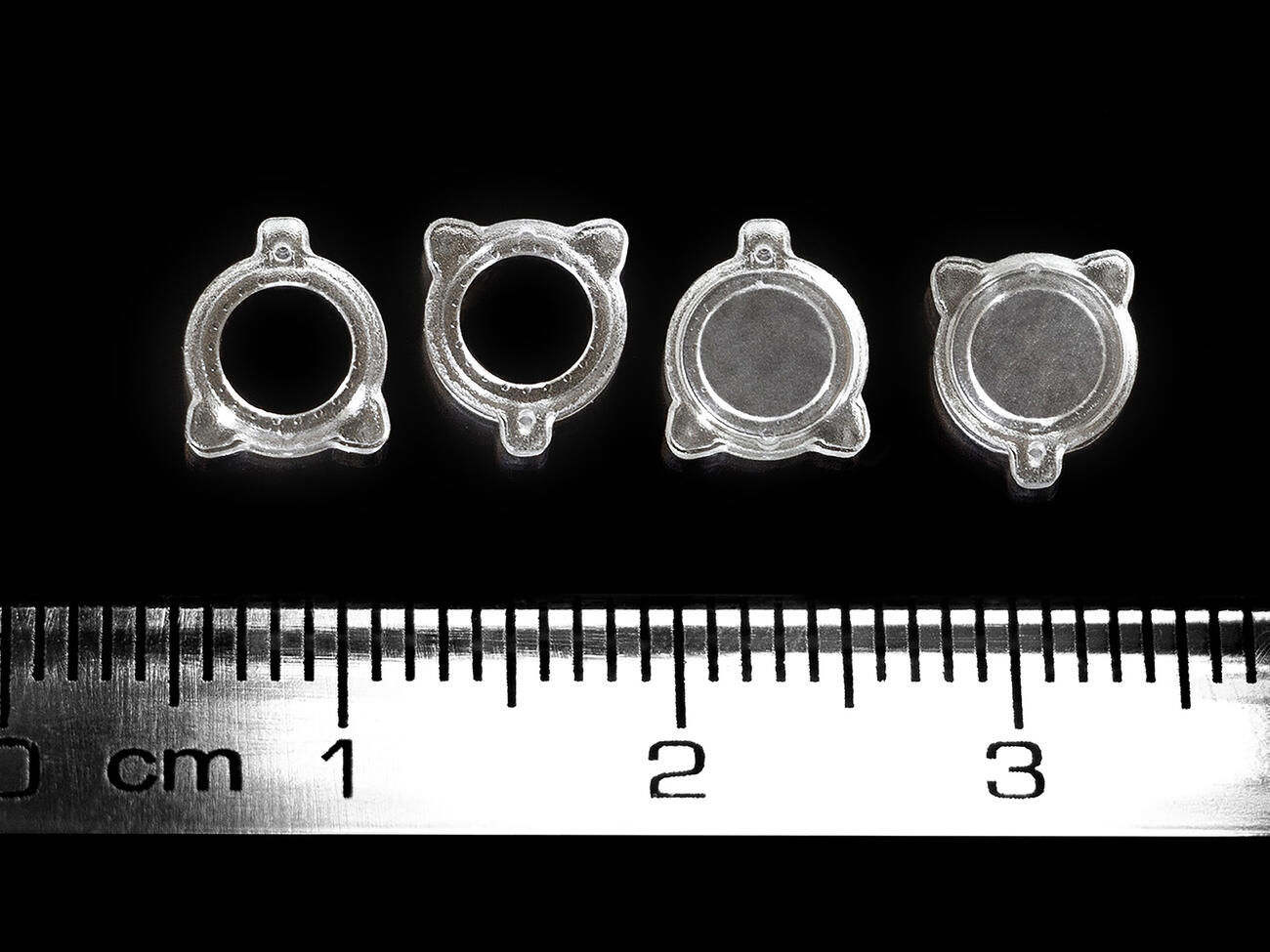

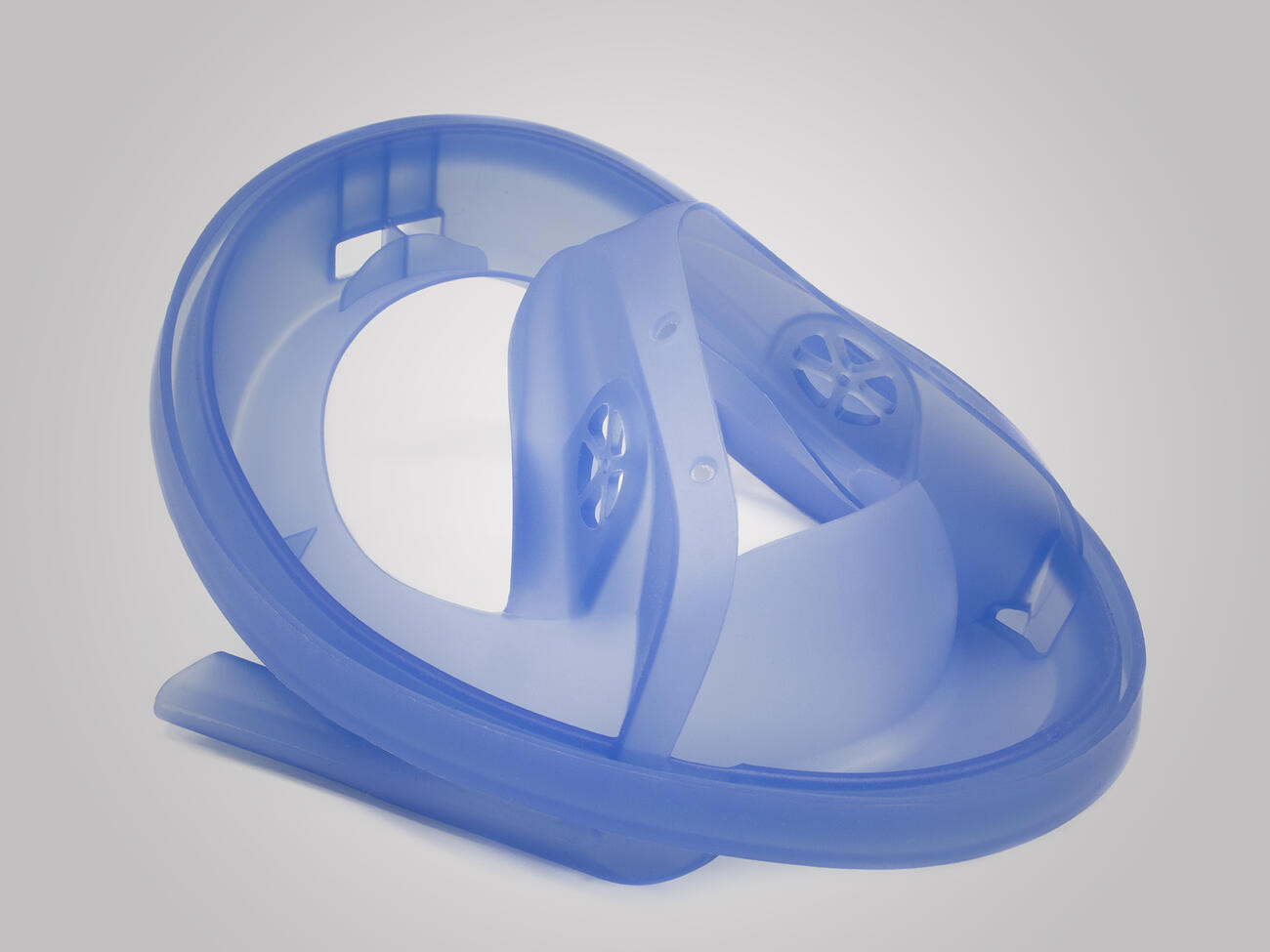

Support ring with a silicone membrane

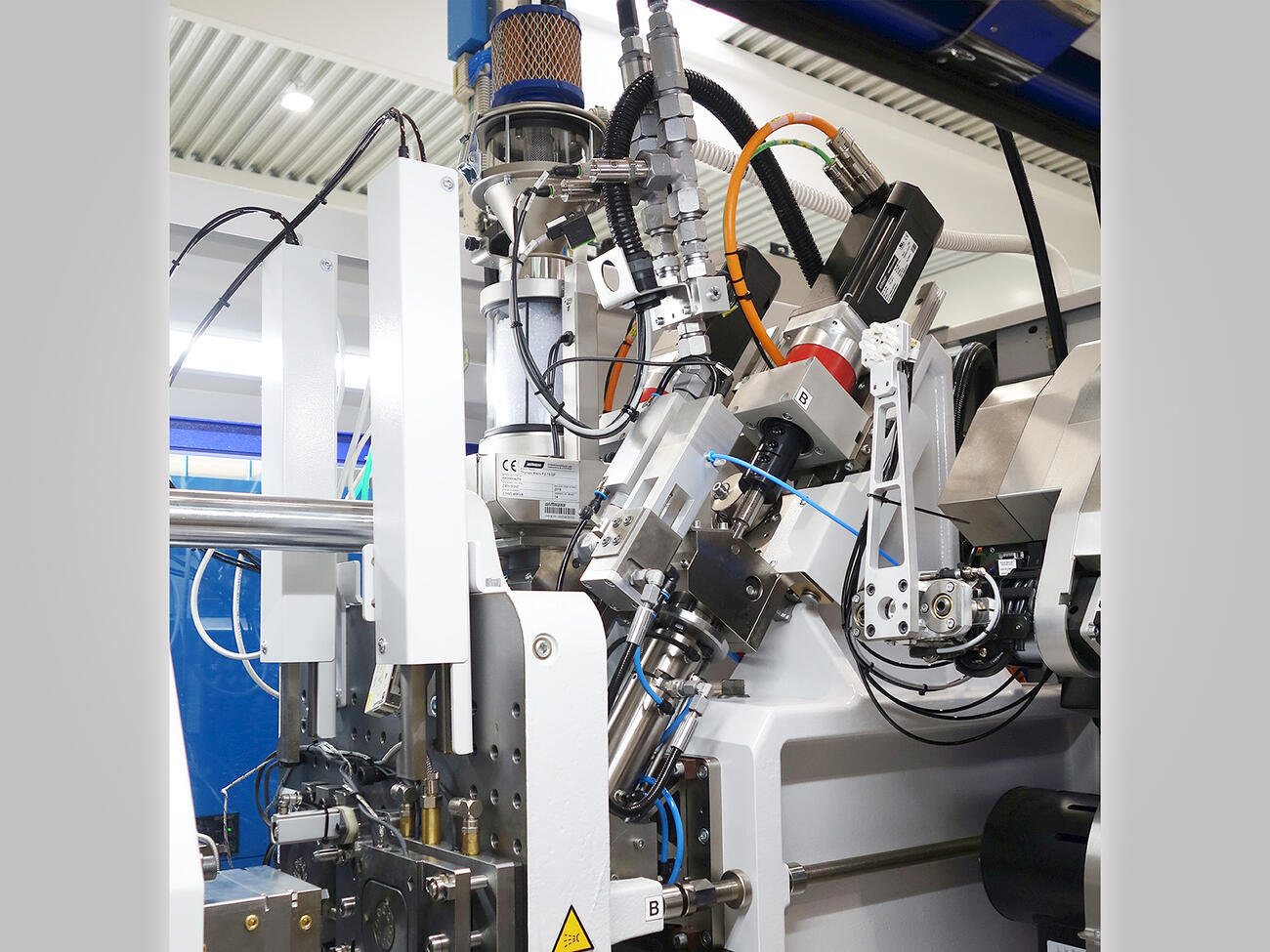

At the Fakuma 2021 in hall B1, booth 1204, WITTMANN BATTENFELD will manufacture a support ring with a silicone membrane to demonstrate its expertise in two disciplines: liquid silicone processing and the production of top-quality micro parts.

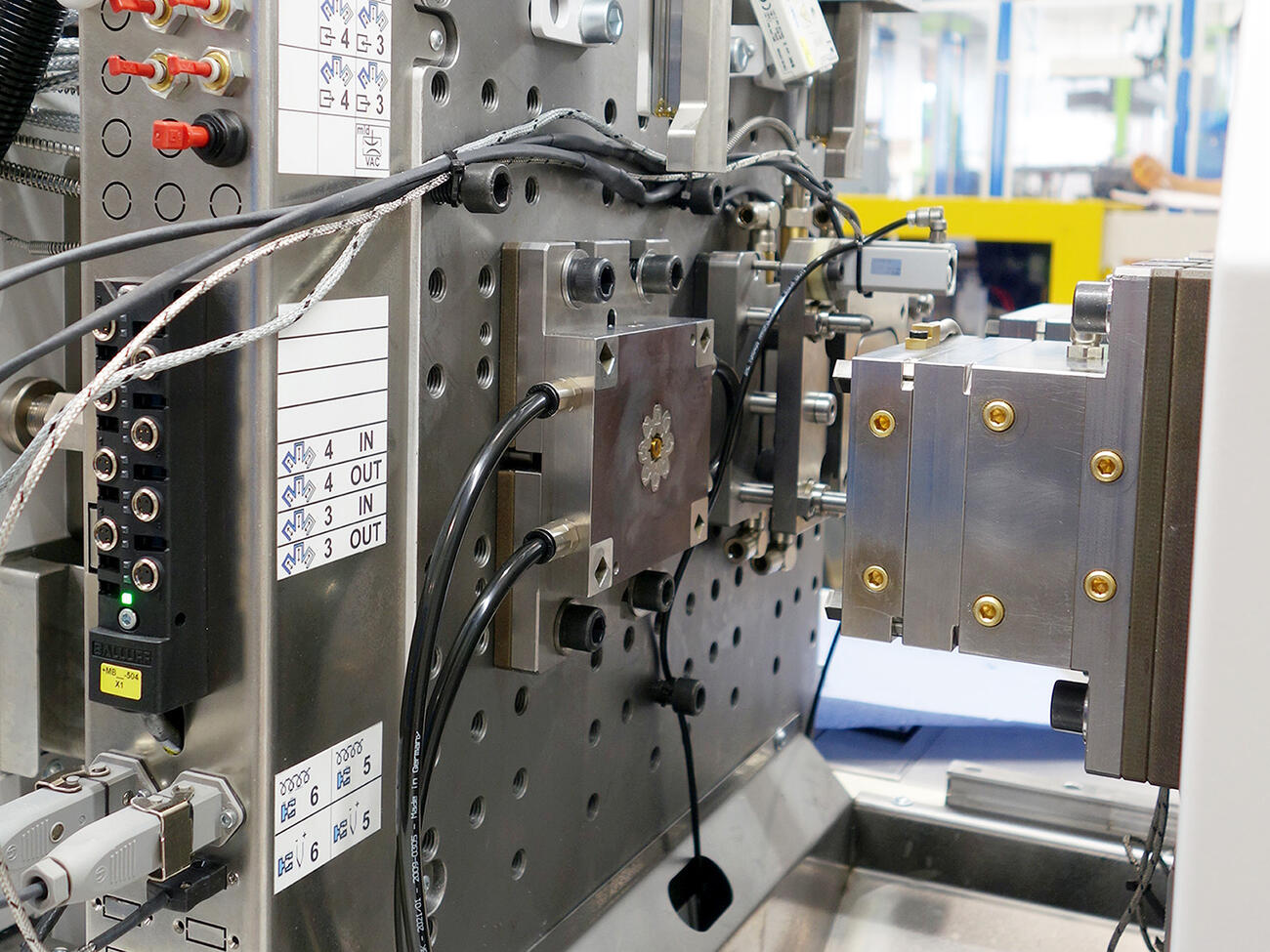

The micro part produced in a 2C process is a support ring used in industrial metrology. The parts are manufactured in an 8-cavity mold constructed in cooperation with Nexus. The materials used are polycarbonate (Macrolon) from Covestro and a self-adhesive LSR (Silopren) supplied by Momentive.

With a diameter of about 6 mm, a height of 1.8 mm and a total part weight of just 23 mg, the uncontested highlight is the silicone membrane, which weighs no more than 120 µg. This extremely thin membrane, only 20 µm thick, permits accurate transmission of even minute pressure differences between two different media. Thanks to the optimal choice of materials, neither high operating temperatures of up to 150° C nor difficult media will present any problems.

Downloads