Perfect resource-saving production

Perfect resource-saving production

Micro injection molding – producing precisely and more efficiently

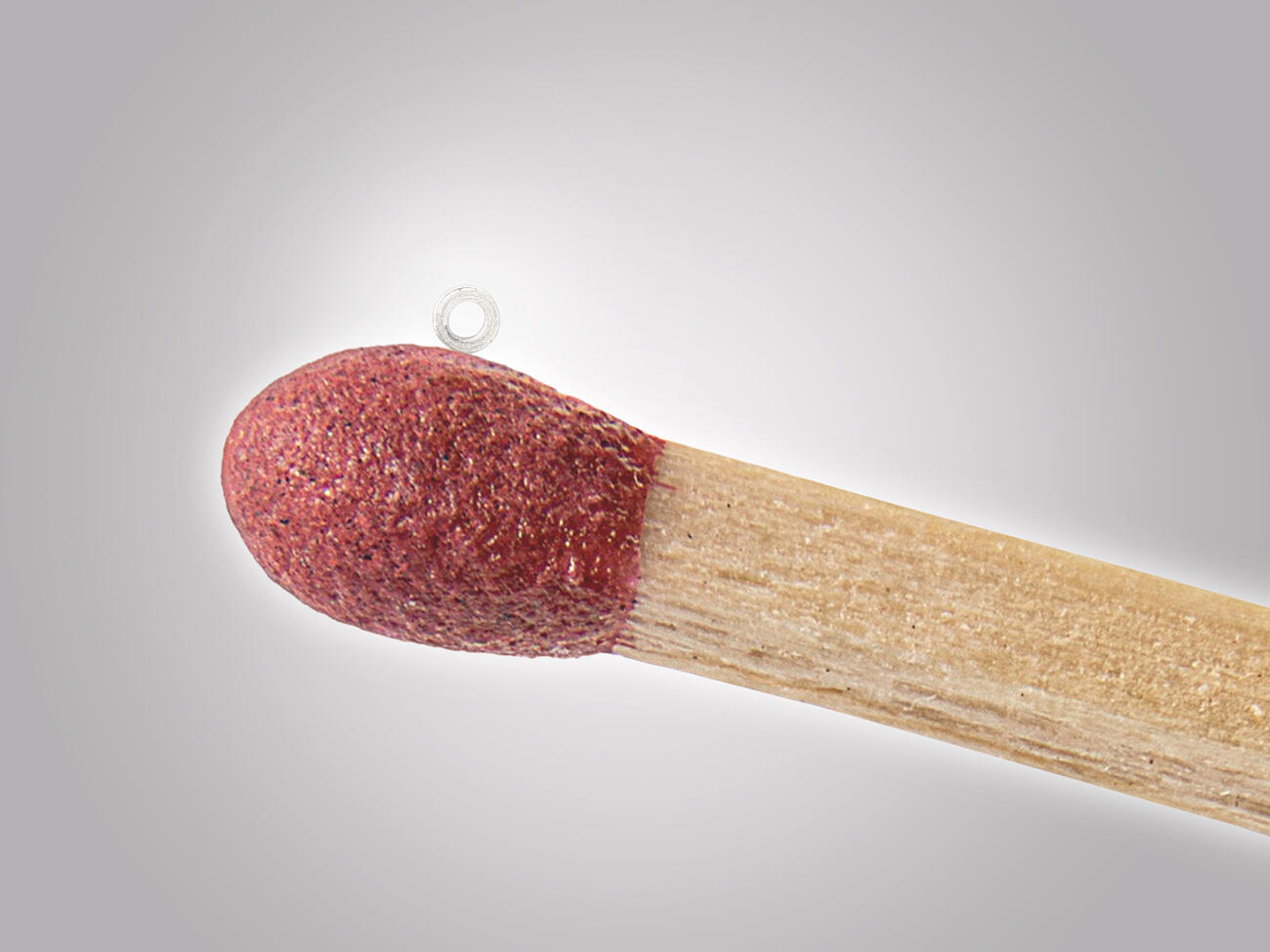

Small – micro – MicroPower

The all-electric Micropower injection molding machine is the perfect example of how to achieve maximum efficiency, precision and energy savings in the smallest possible space, whilst also reducing overall production costs. Thanks to the 2-stage screw-piston injection system, it is possible to minimise the sprue volume and achieve the highest precision during the injection process.

The key to optimal production is the reduction of sprue size. The shorter the flow paths and the smaller the mass cushion between the plunger and the component, the more dynamically, precisely and consistently the process can be controlled.

Due to the modular nature of the machine, the customer is able to choose between different configurations. From the classic "on-off" solution for free-falling components to a complete production cell including automation and inline quality control, the modular options leave nothing to be desired. In addition, the MicroPower can also be equipped, for example, with an air filter and laminar flow unit that enables Class 7 cleanroom production in accordance with 14644-1. The molded parts produced can then be deposited using cavity separation within the cleanroom cell.

The MicroPower in the Combimould version can also meet the increasing demand for multi-component micro and precision parts. Here, too, the modular design allows the customer to choose the optimum industry-specific configuration, enabling efficient, precise and cost-effective production in the smallest possible installation space.

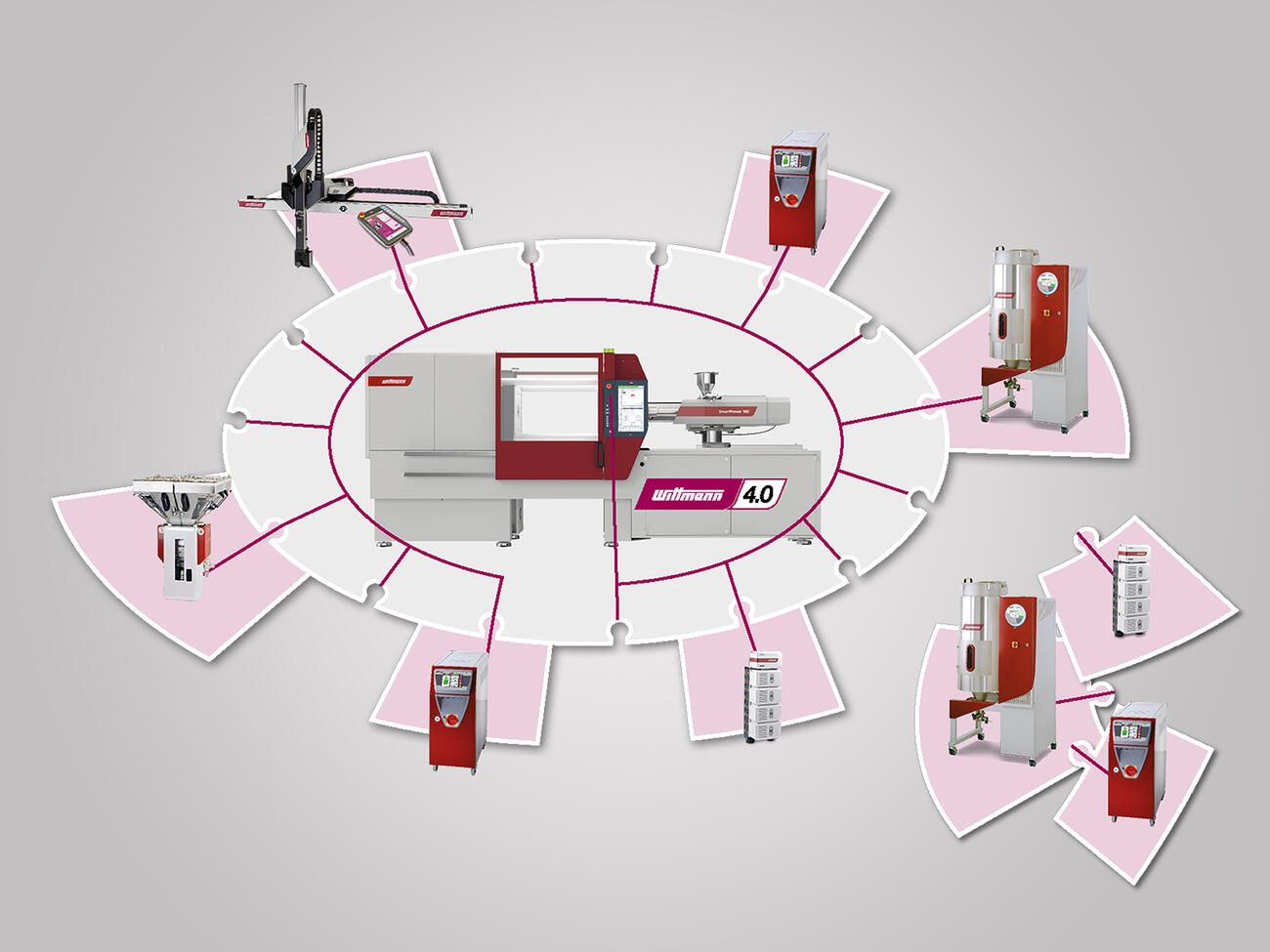

Another major contribution to successful production is in the area of data management and processing. Both setting and process parameters can be processed in a controlled manner via the existing interfaces. And thanks to the Wittmann 4.0 full integration of the auxiliary devices, the Unilog B8 machine control ultimately serves as the central hub for the user. This completely eliminates the need for error-prone merging of different settings and parameters from auxiliary devices.

'The overall machine concept of the MicroPower provides the perfect symbiosis of precision, speed and robustness. This enables our customers to produce perfectly-made small and micro parts in a resource-saving, energy-efficient and cost-effective manner –

all from a minimal factory footprint.'

Martin Philipp-Pichler, Project Engineer – Micro Injection Molding at WITTMANN BATTENFELD

Downloads