Light and easy production

Light and easy production

... thanks to Cellmould light-weight technology perfected over many years of research

Cellmould Light-weight technology in perfection

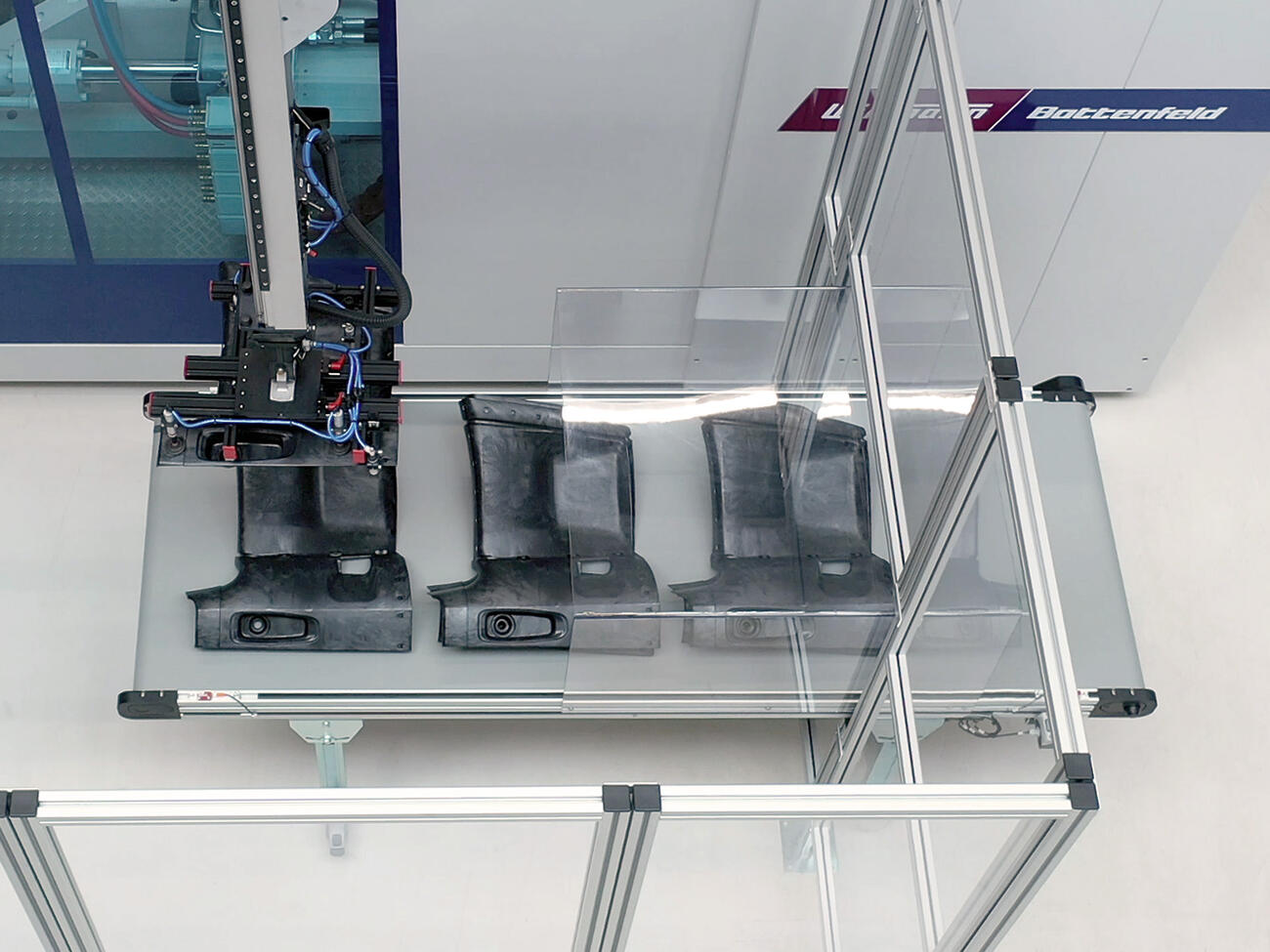

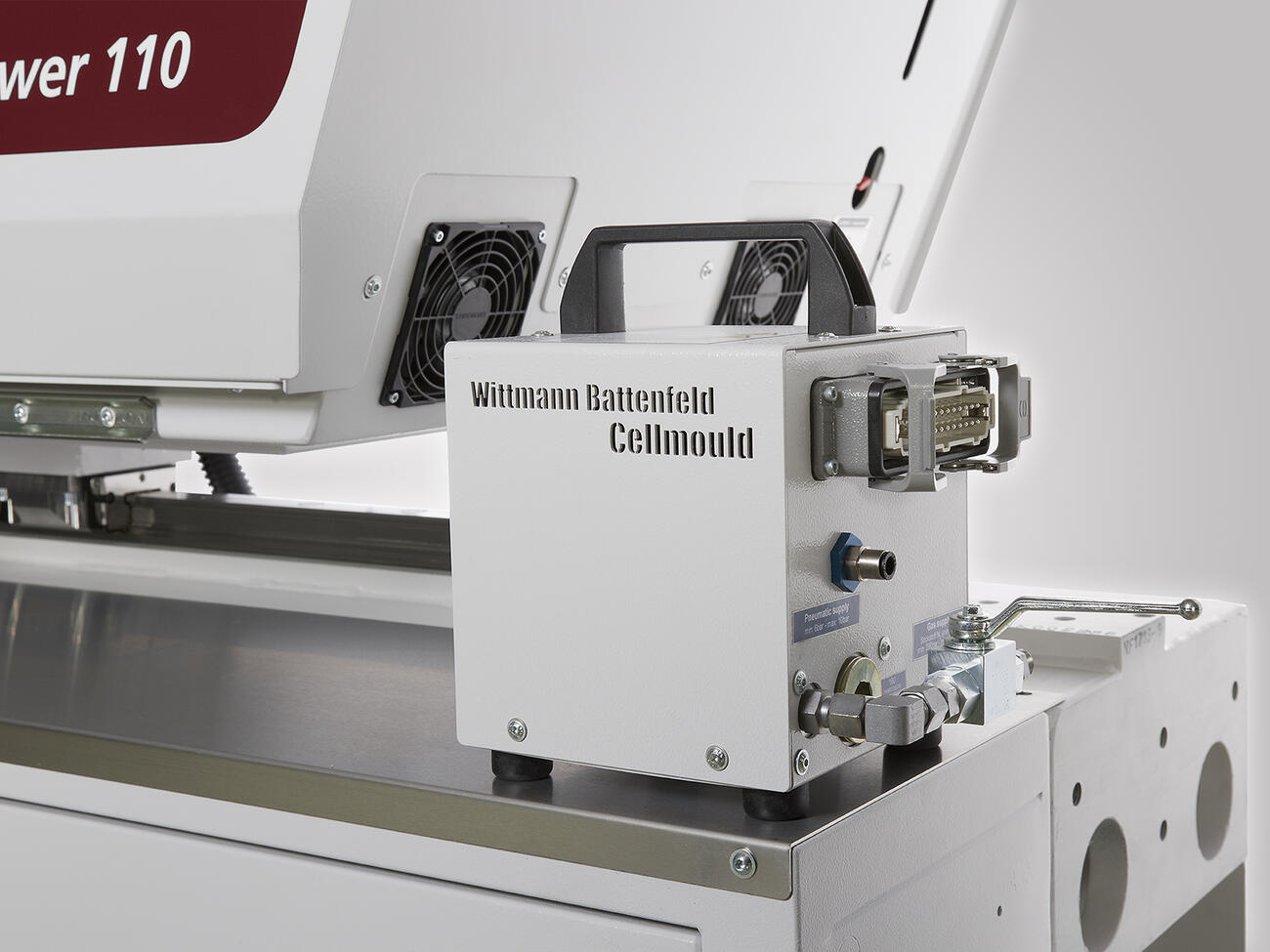

Cellmould is WITTMANN BATTENFELD's own foam injection molding process and guarantees the best results. Sink marks and warpage are a thing of the past. The process can be used for both thick-walled and thin-walled parts and allows for significant weight reduction. This results in advantages not only in the automotive industry but also for parts used in transport such as containers and pallets. In addition to the weight reduction, there are also cost savings due to the reduced plastic material consumption.

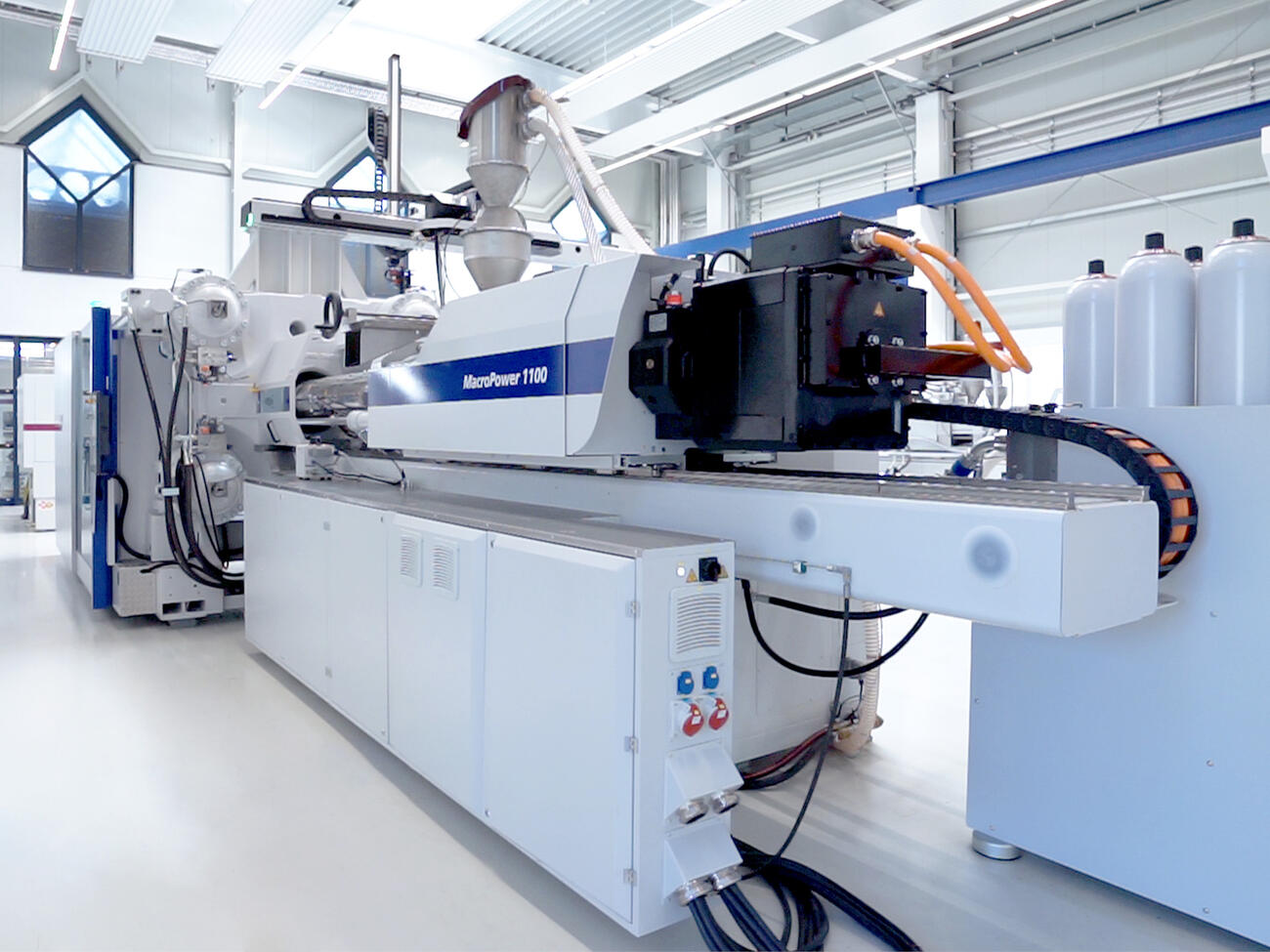

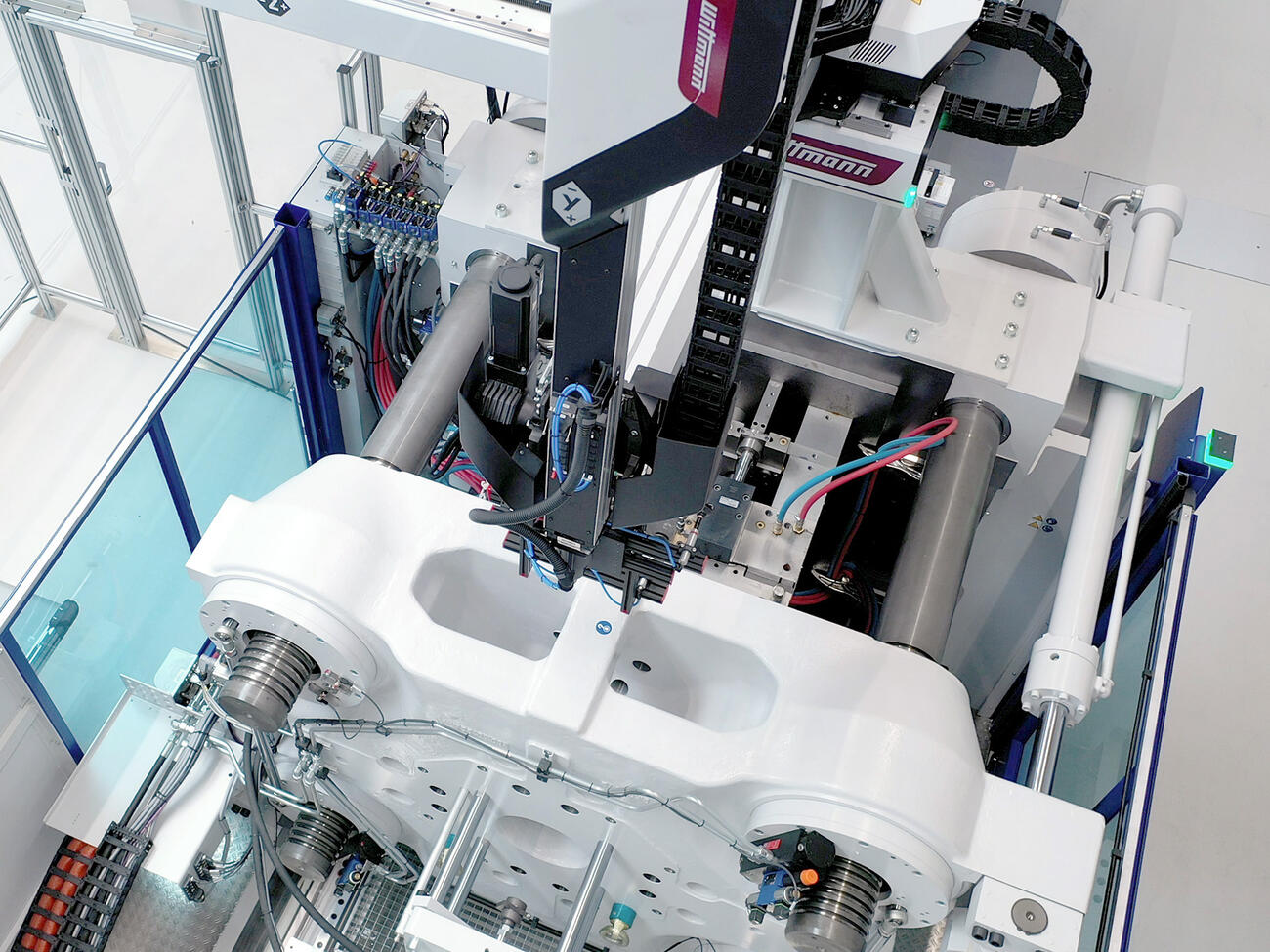

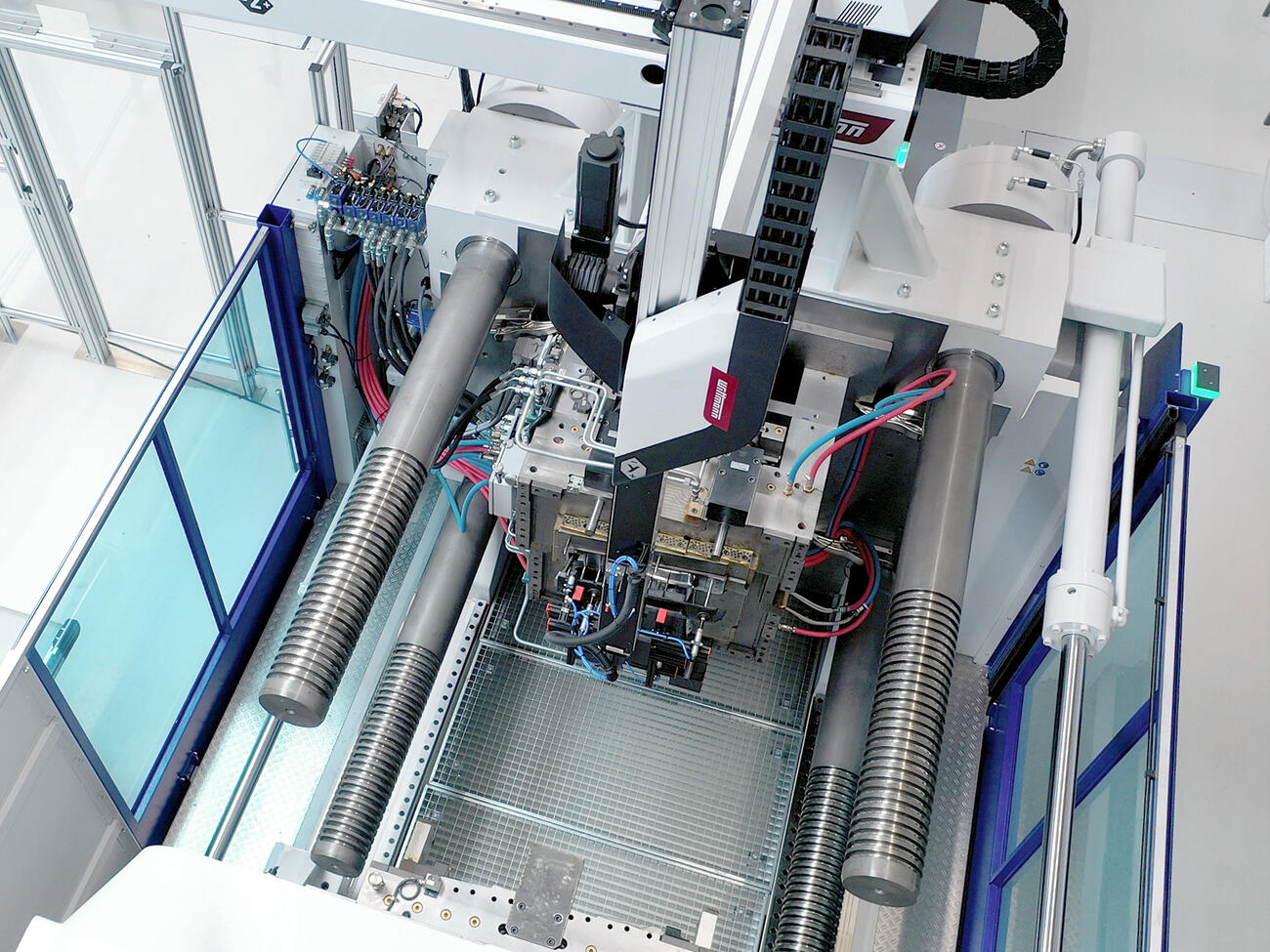

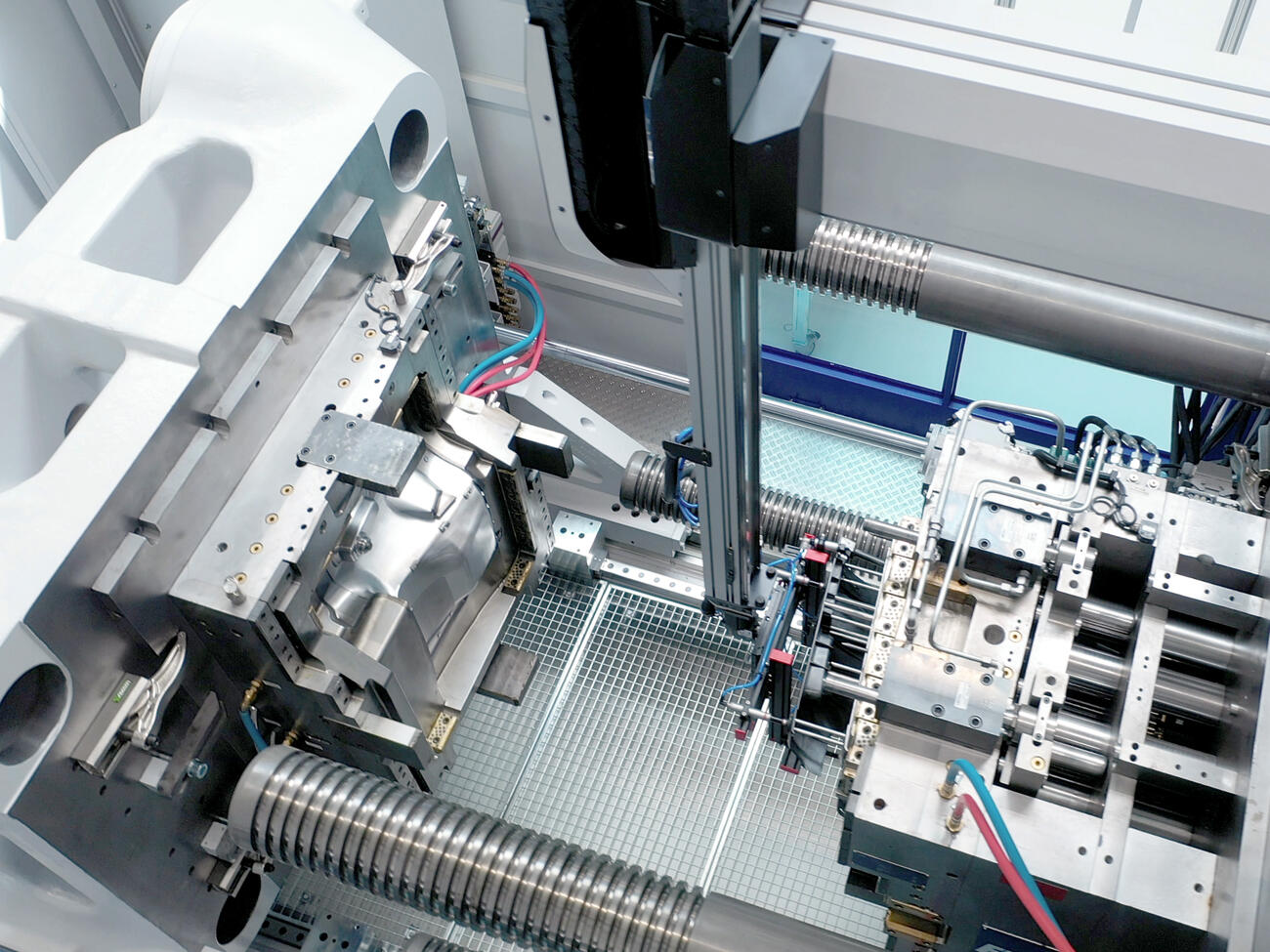

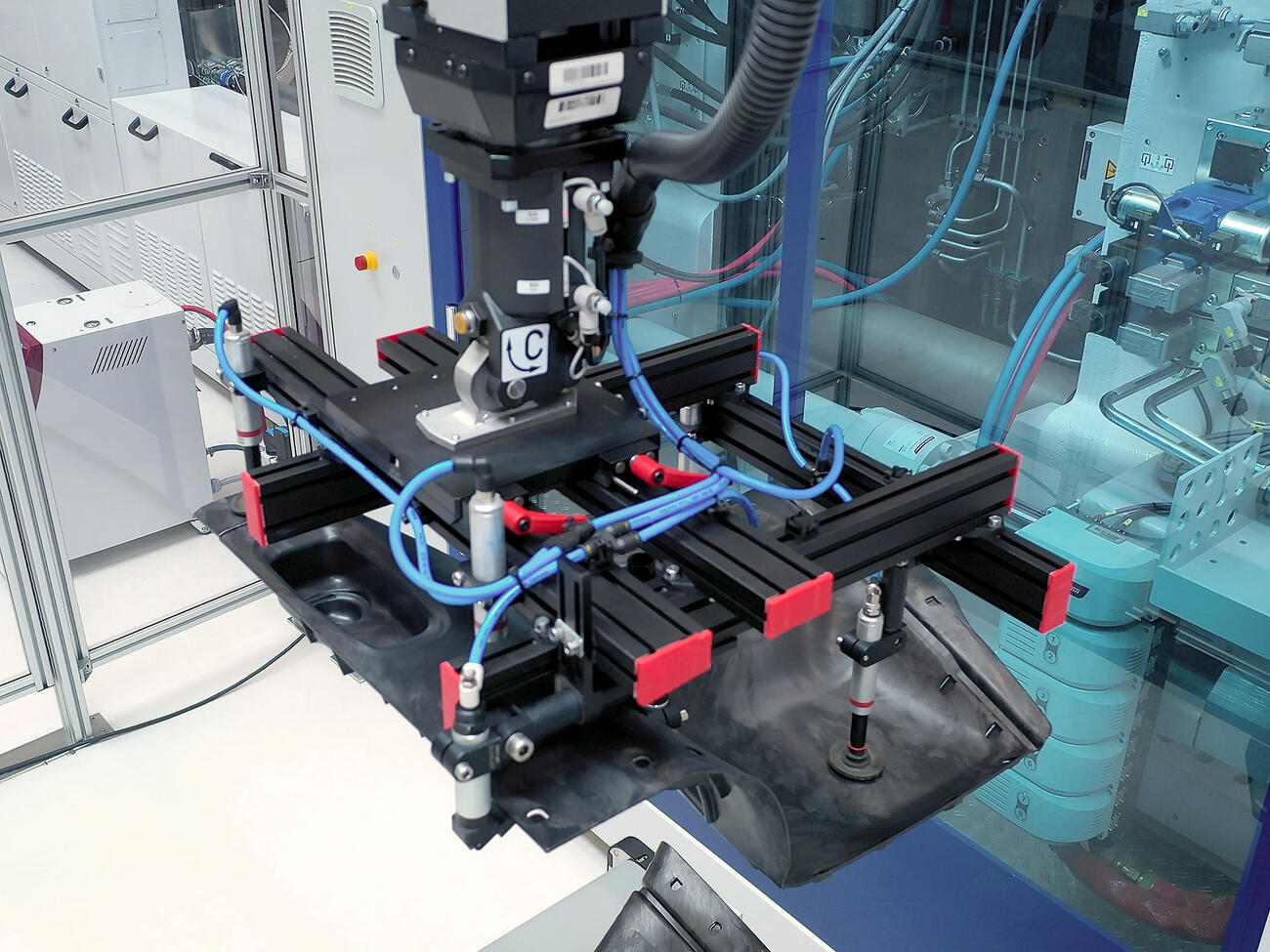

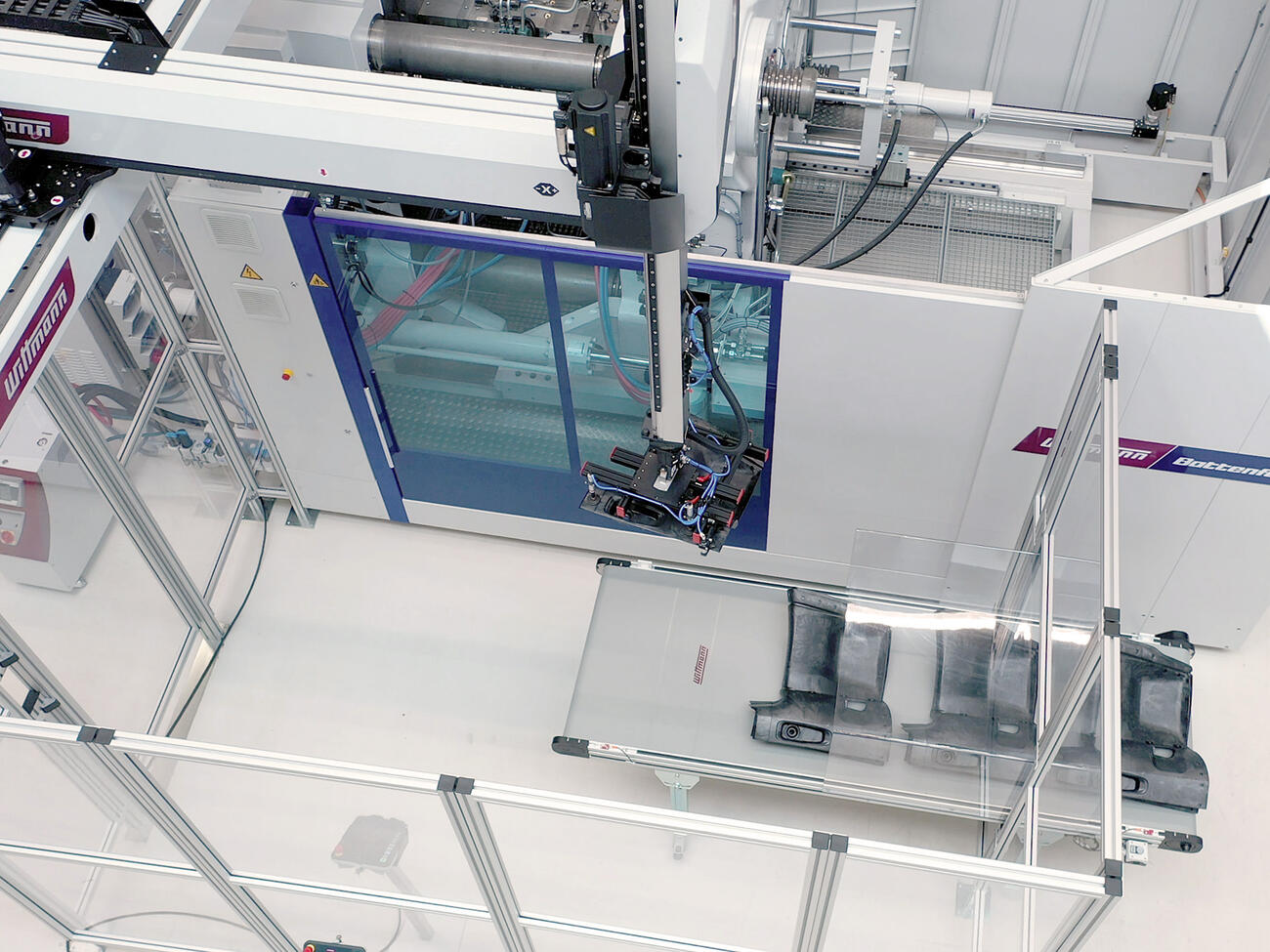

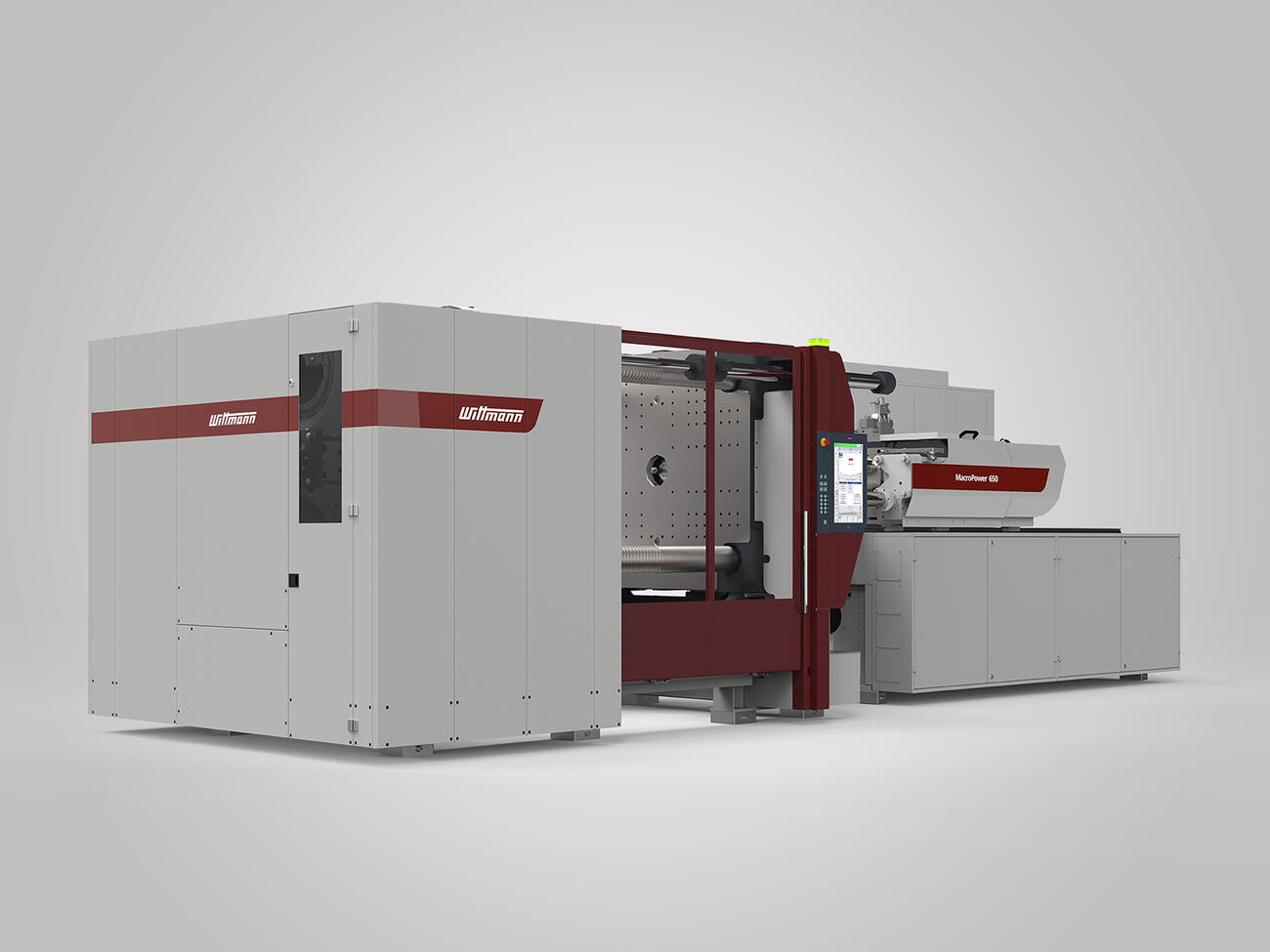

For impressive results and the manufacture of high-quality products, the injection molding machine, the Cellmelt screw, the nitrogen and pressure generation unit and the Cellmould control module are optimally fine-tuned together. The Cellmould process is demonstrated by the MacroPower 1100 t, which uses structural foam technology to produce a PP seat bench carrier for a German sports car company.

The entire Cellmould technology was developed by WITTMANN BATTENFELD during many years of research. By manufacturing the complete system including auxiliaries in-house, WITTMANN BATTENFELD customers enjoy the advantage of sourcing everything in one place according to the "One-Stop-Shop" principle – from the injection molding machine to the physical foaming equipment.

'We are very proud that we are able to offer our customers a great Cellmould solution for a large number of their technical and commercial needs.'

Marco Moser, product expert for the structural foam process and gas injection technology at WITTMANN BATTENFELD

Downloads