With smart LSR application at the DKT in Nuremberg

With smart LSR application at the DKT in Nuremberg

Come and visit us at booth No. 503 in hall 09

From 27 to 30 June 2022, WITTMANN BATTENFELD will present state-of-the-art injection molding technology for LSR processing to visitors of the German Rubber Conference DKT in Nuremberg at its booth No. 503 in hall 09.

WITTMANN BATTENFELD has already been active in the field of LSR processing for a number of years. The DKT is an important platform for the WITTMANN Group to demonstrate its expertise in this field to a wide professional audience.

Two exhibits will be showcased at this year’s DKT. Firstly, liquid silicone processing will be shown on a machine from the servo-hydraulic SmartPower series. Apart from their compact footprint and user-friendliness, the machines of this series stand out primarily by their intelligent and economical energy utilization achieved by a fast-response, speed-controlled, air-cooled servo motor combined with a highly efficient constant displacement pump. Secondly, the production of a micro part with a silicone membrane will be presented on a multi-component MicroPower machine specially designed for manufacturing micro parts.

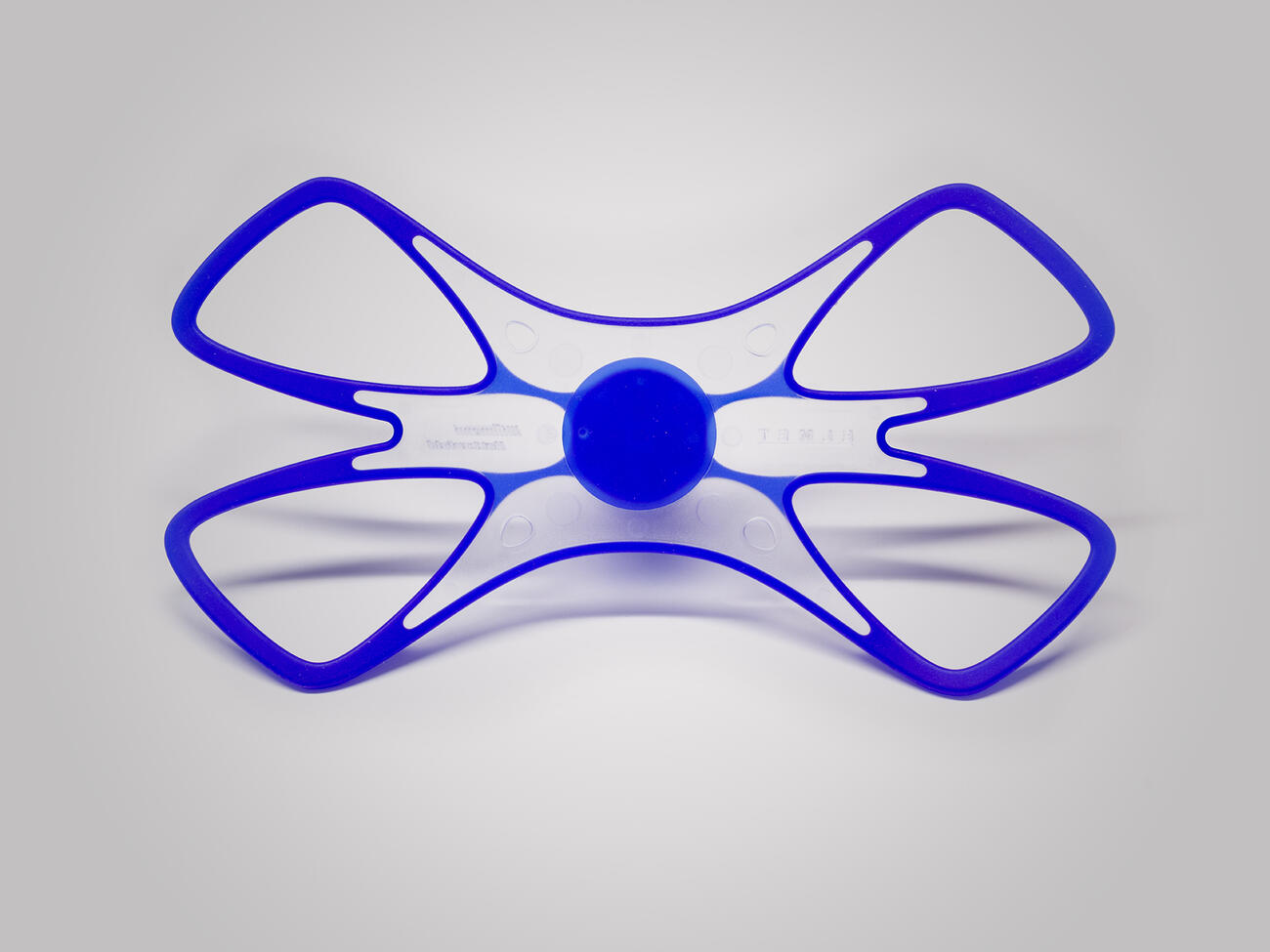

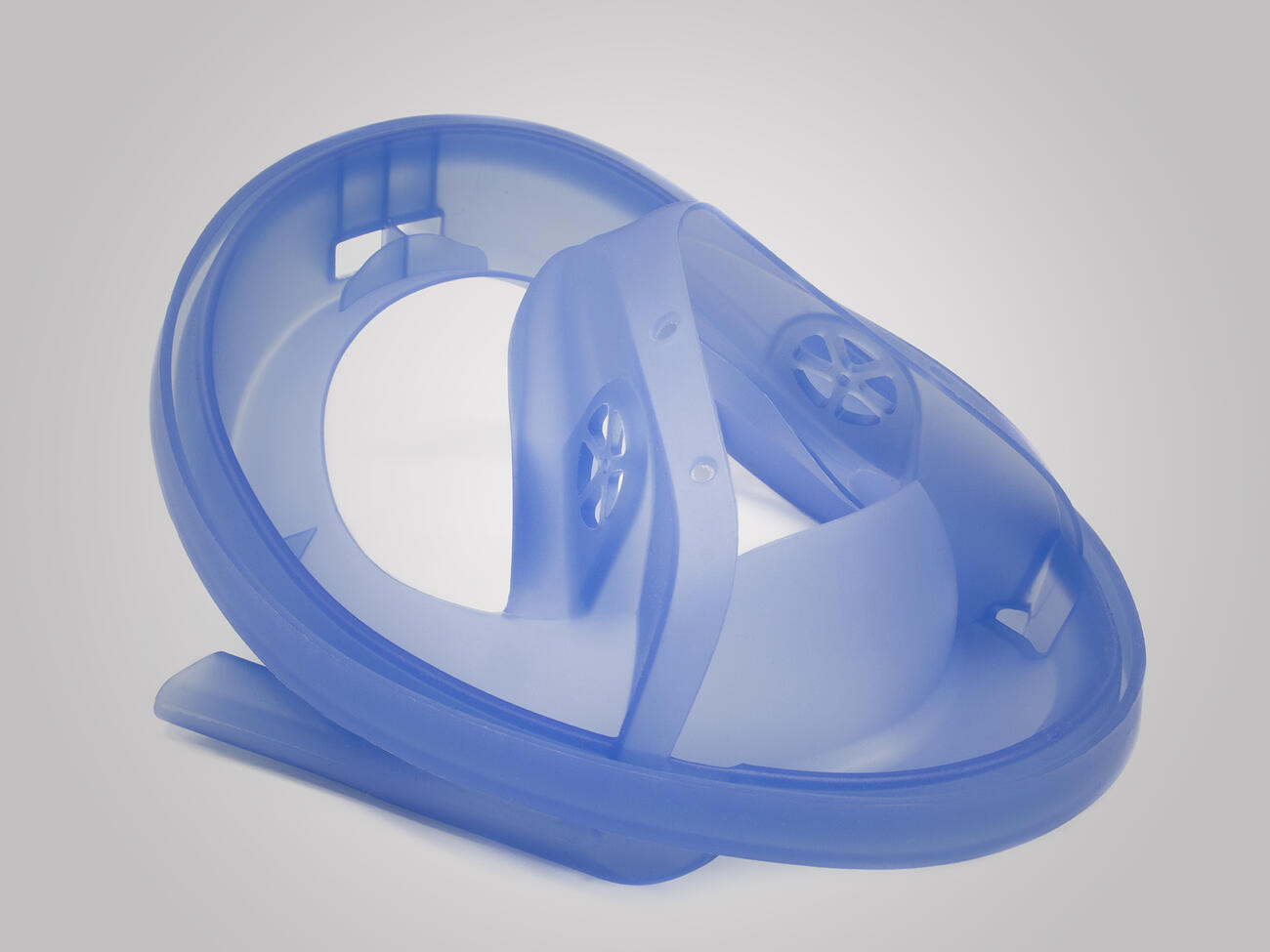

With a multi-component machine from the servo-hydraulic SmartPower series, a SmartPower 120/130H/130S Combimould LSR, a mobile phone holder will be manufactured from PC and LSR, using a 1+1 transfer mold with a needle shut-off cold runner supplied by Elmet, Austria. The machine will be equipped with a W921 robot, a Tempro plus D2 140 dual-circuit temperature controller and an Aton plus 30 dryer, all from WITTMANN, as well as a Top 5000P metering pump from Elmet. The LSR used from Momentive is Siloprene LSR 2759, a material characterized by excellent adhesion to the PC provided by Covestro. The material loading system for the thermoplastic component is geared to handling extremely small quantities, to avoid remoisturizing after transport.

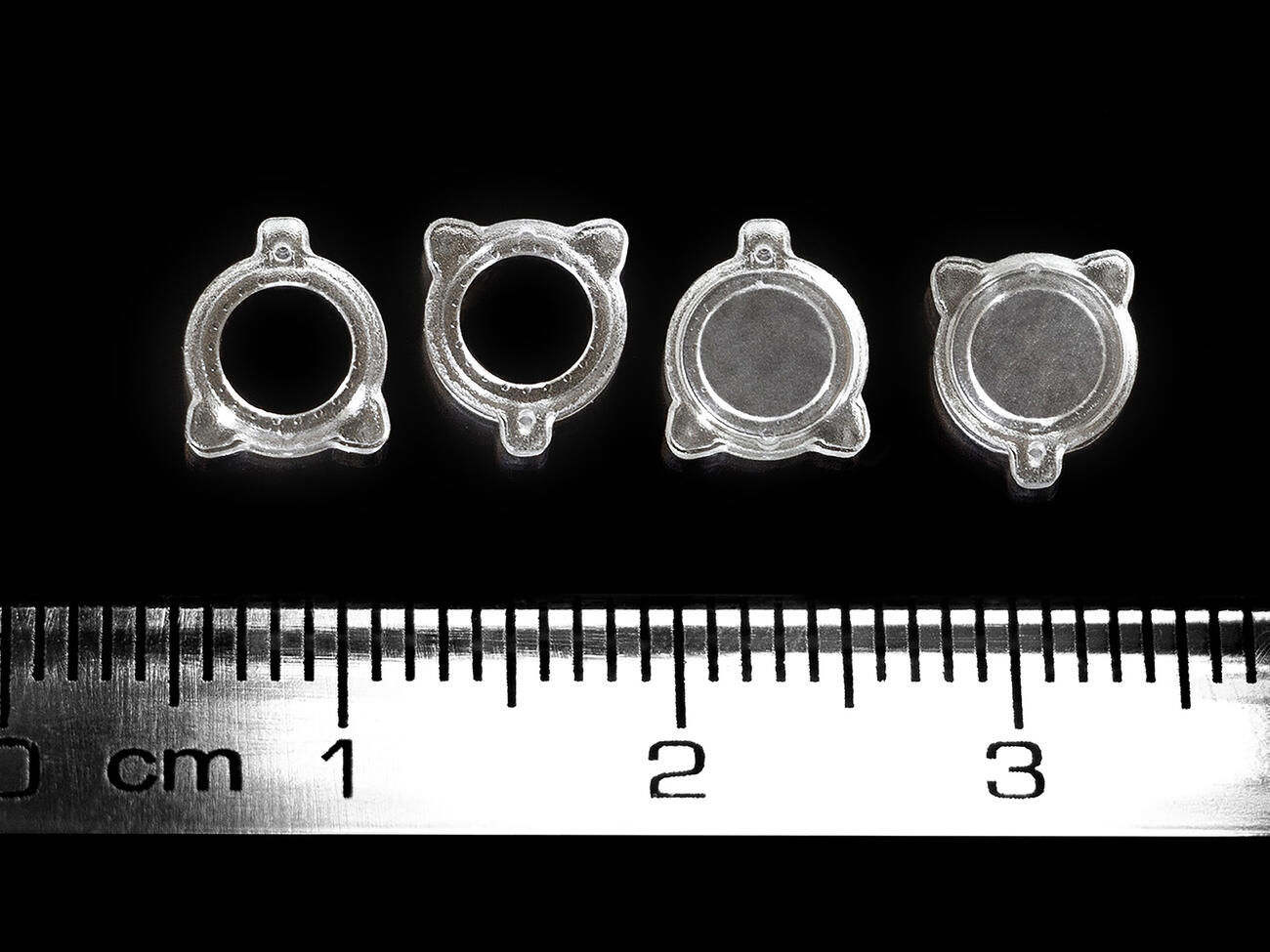

LSR processing in the area of micro parts will be demonstrated by producing a support ring with a silicone membrane on a MicroPower 15/10H/10H Combimould LSR. This micro part, manufactured in a 2C process, is used in industrial measurement technology. The 8-cavity mold used to manufacture these parts was produced in cooperation with Nexus. The materials used are polycarbonate (Macrolon) supplied by Covestro and a self-adhesive LSR (Siloprene) from Momentive. The silicone membrane of the support ring, no more than 20 µm thick, makes it possible to transmit accurately even the most minute pressure variations between two different media. The LSR is fed to the machine from cartridges, the material flows are measured by a liquid dosing unit designed for quantities in the microliter range. Simultaneously, the high material quality is documented and transmitted to the machine’s B8 control system via an OPC-UA interface (Euromap 82.3). The “Servomix X1” liquid dosing unit contributed by Nexus completes the package.

Downloads