Uncompromising precision of the VPower Combimould

Uncompromising precision of the VPower Combimould

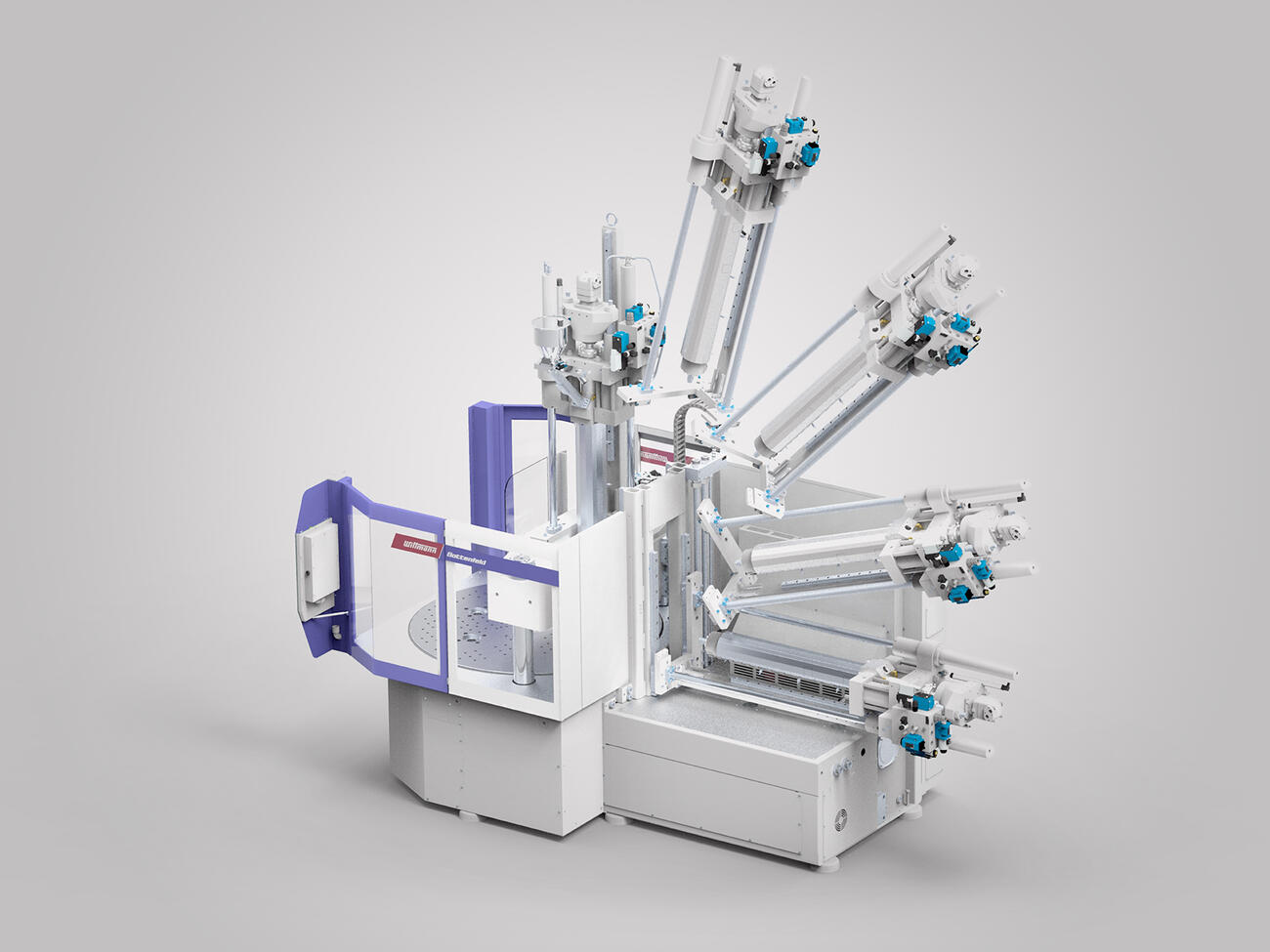

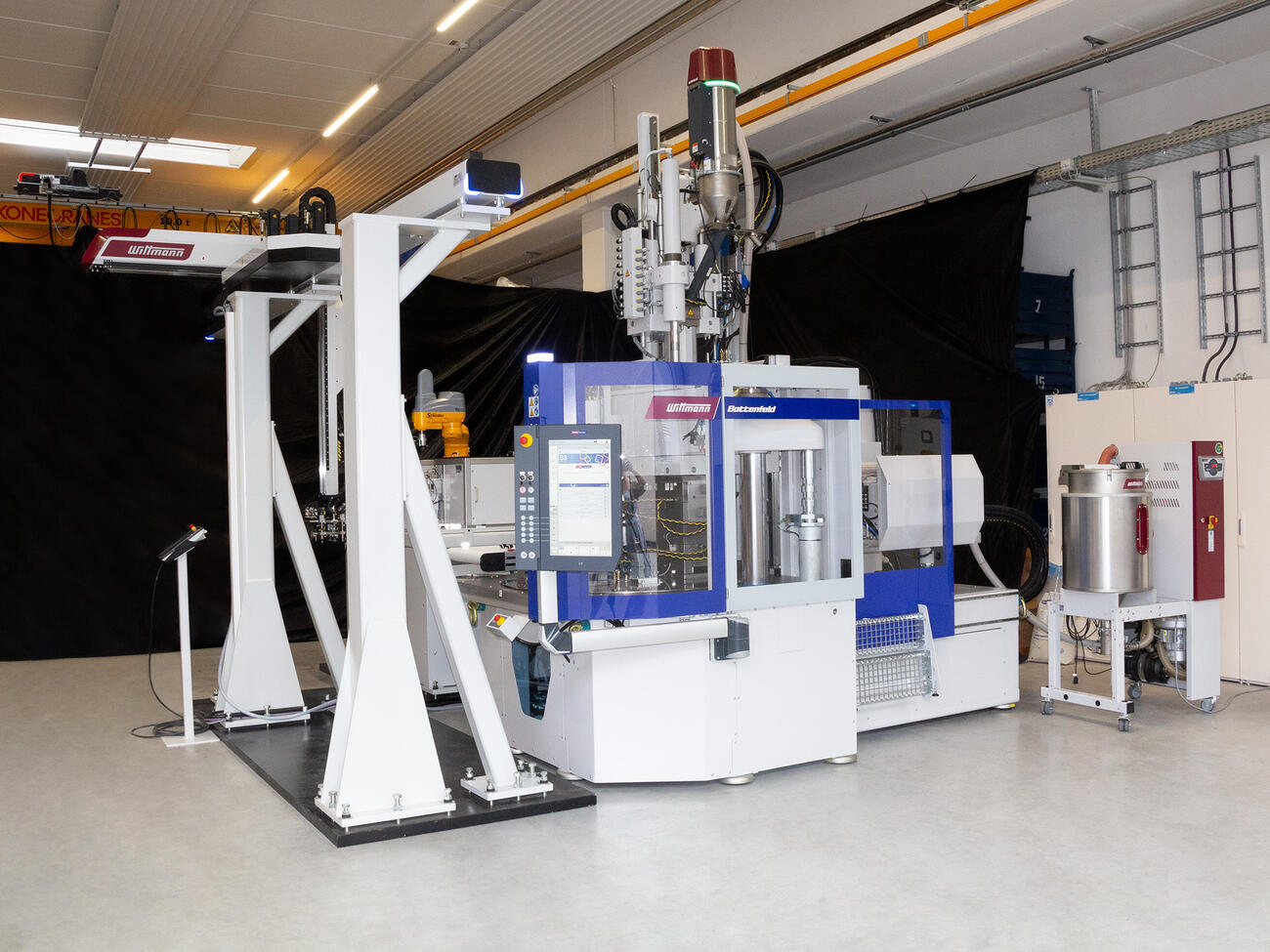

Modern vertical molding machine designed for highest accessibility and automation

For flexible assembly injection molding

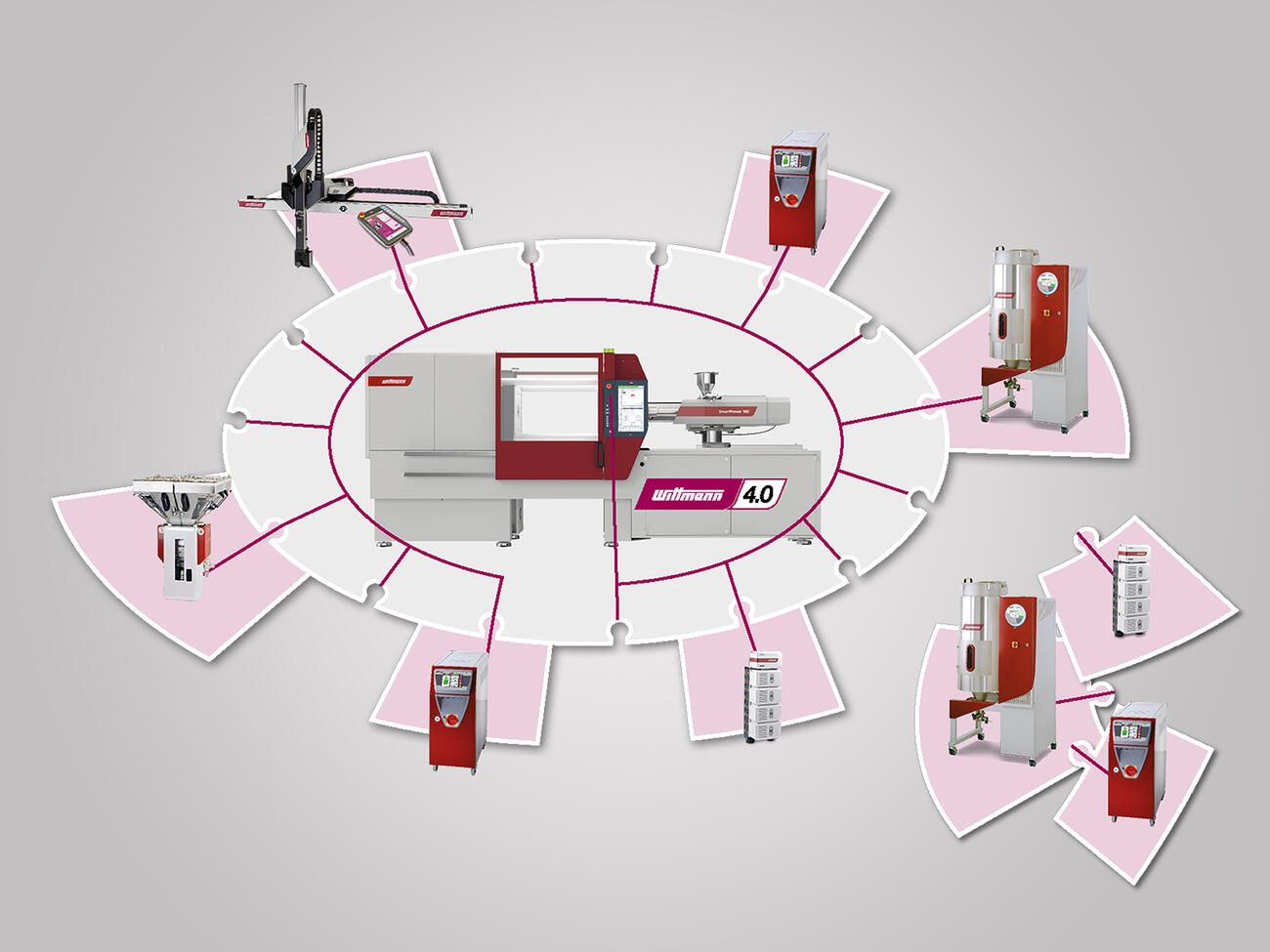

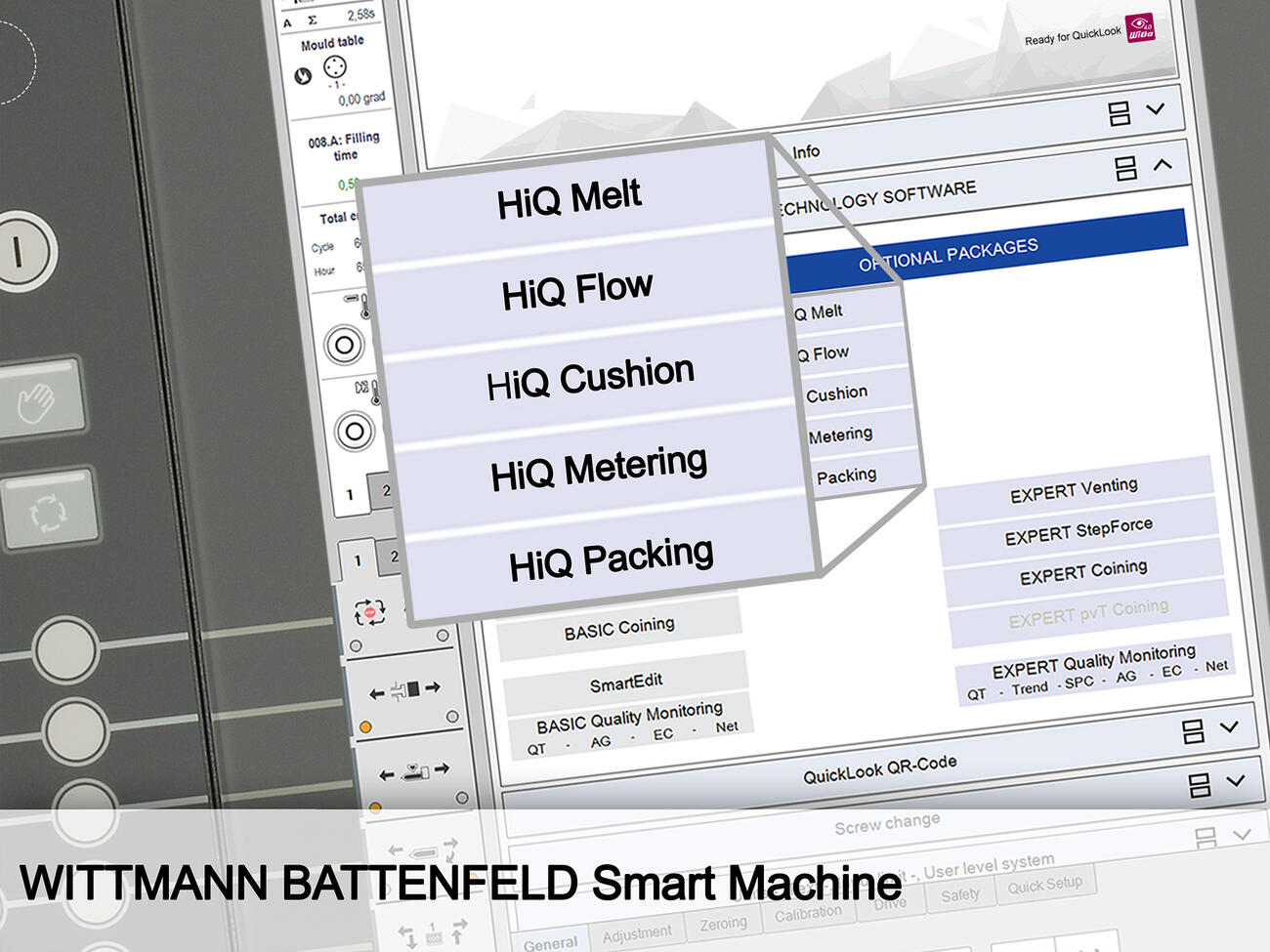

The VPower series stands for highest part quality. This is achieved through state-of-the-art injection molding technologies, such as the HiQ software packages, and through homogeneous force application using the patented Uniforce concept. The VPower also enables maximum productivity through part removal parallel to injection molding and easy changeover of the injection unit. If the machine is pre-prepared for conversion from horizontal to vertical from the factory, changeovers can then be quickly made during production.The VPower is also available in a 2-component version. These advantages and many more are demonstrated by the Combimould version of the VPower 120/130H/210V R1300, which is used to produce a connector for the automotive industry from PA and TPE using a 2+2 cavity mold.

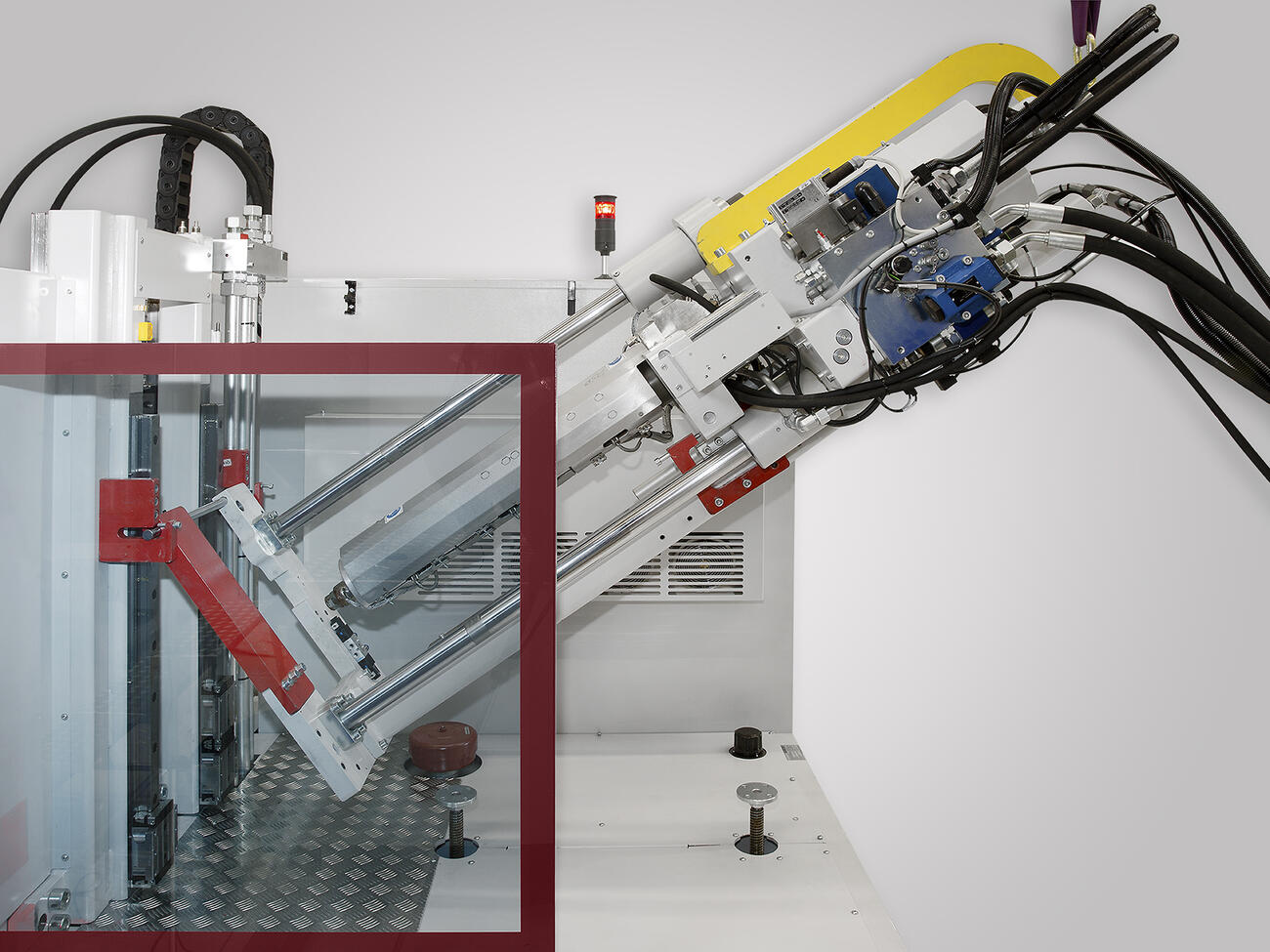

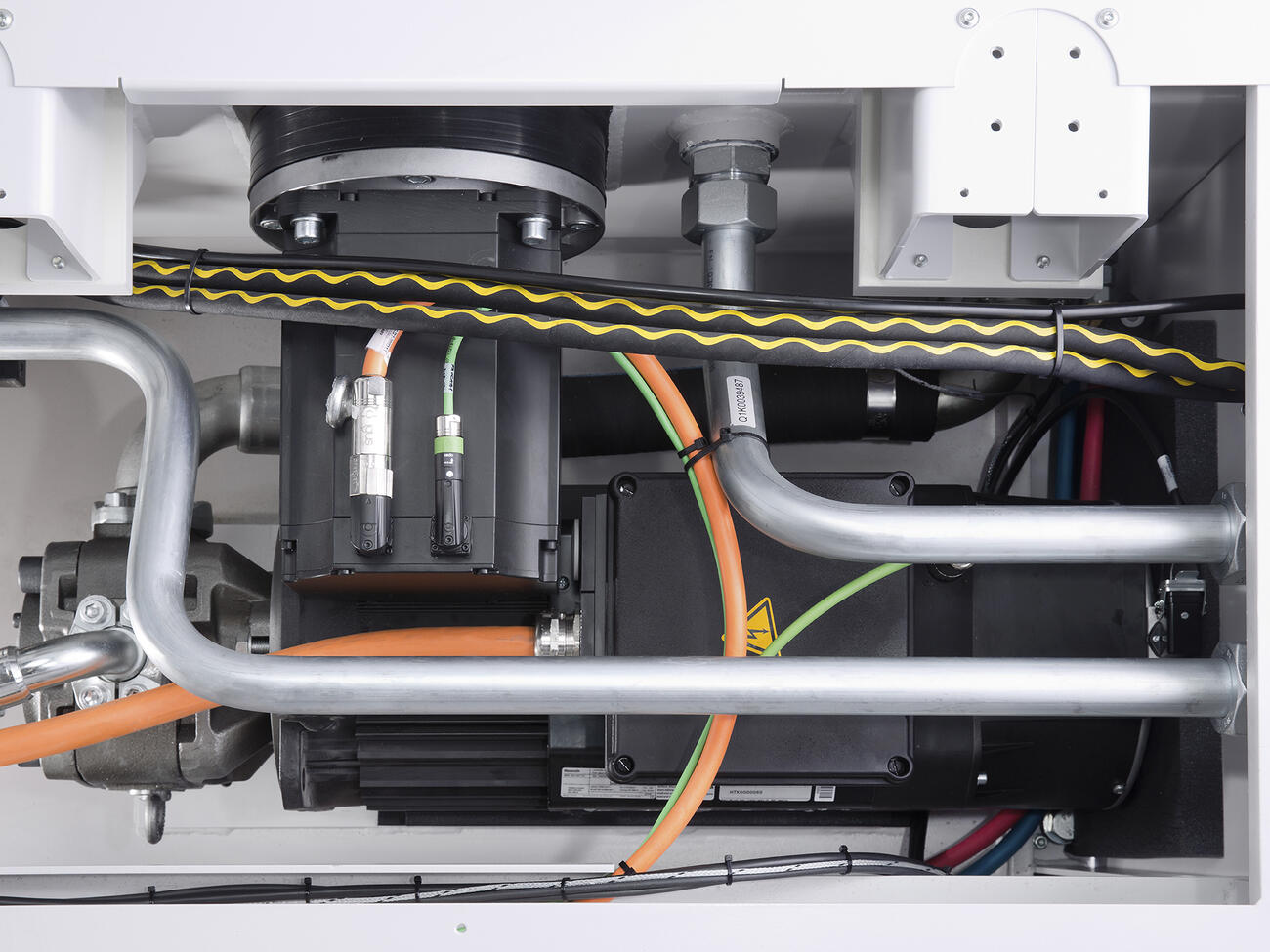

The machine is characterized by its minimal space requirement, the particularly low ergonomic working height of less than one meter and the free accessibility to all important areas of the machine. For example, the mold area is easily accessible from all sides. Another plus is the double drip protection of the V-unit from the plasticized plastic compound by the automatically retractable ejection tray as well as by the needle shut-off nozzle.

One major advantage of the VPower series is the specialized Uniforce compensation platen system. This neutralizes the transmission of force-induced deformation of the clamping platen through the compensation platen. This results in a previously unattained uniform distribution of force through the injection mold. This, in turn, reduces wear and thus minimizes downtime and maintenance costs. The tie-bar-less center section of the rotary table also deserves special mention. This not only offers the advantage of unhindered access to the mold, but also enables supply lines through the rotating center via direct hoses in oscillating operation or else a water distributor in a rotating operation. Due to the optimized design, there are also no obstructing elements that could cause collisions here, disturb production or hinder automation.

You can find additional features and benefits either in our product brochure, or visually illustrated in our YouTube video or else in a personal conversation with one of our product experts.

'The VPower is unique among its peers and elegantly combines a compact design with material and energy cost saving factors.'

Christian Glück, Product Expert at WITTMANN BATTENFELD Kottingbrunn

Downloads