Perfectly adjusted plasticizing unit

Perfectly adjusted plasticizing unit

Research and development for your benefit

Years of research and development at the highest level and quality standard

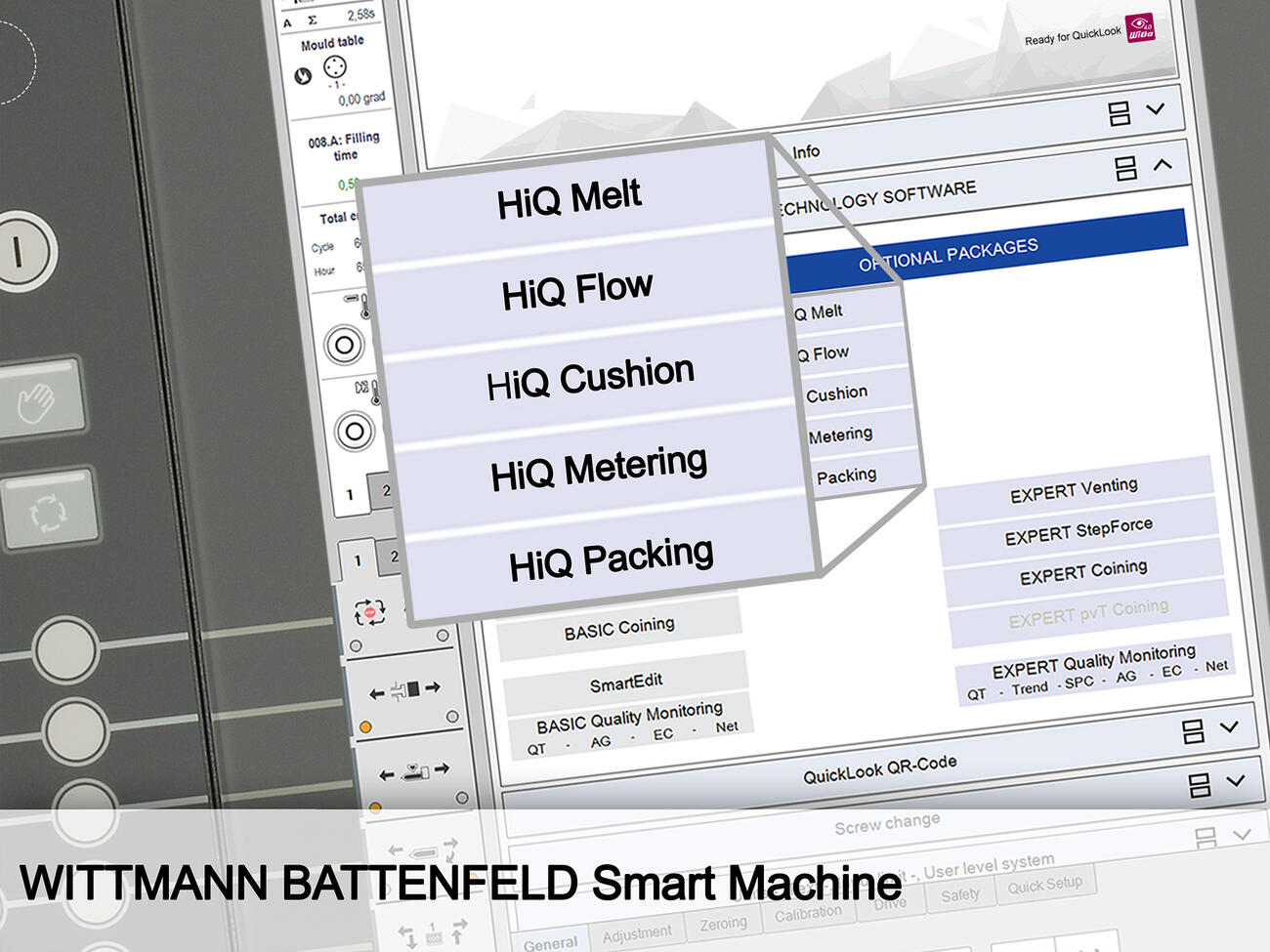

Thanks to decades of experience, WITTMANN BATTENFELD can offer its customers various packages in a tailored manner.

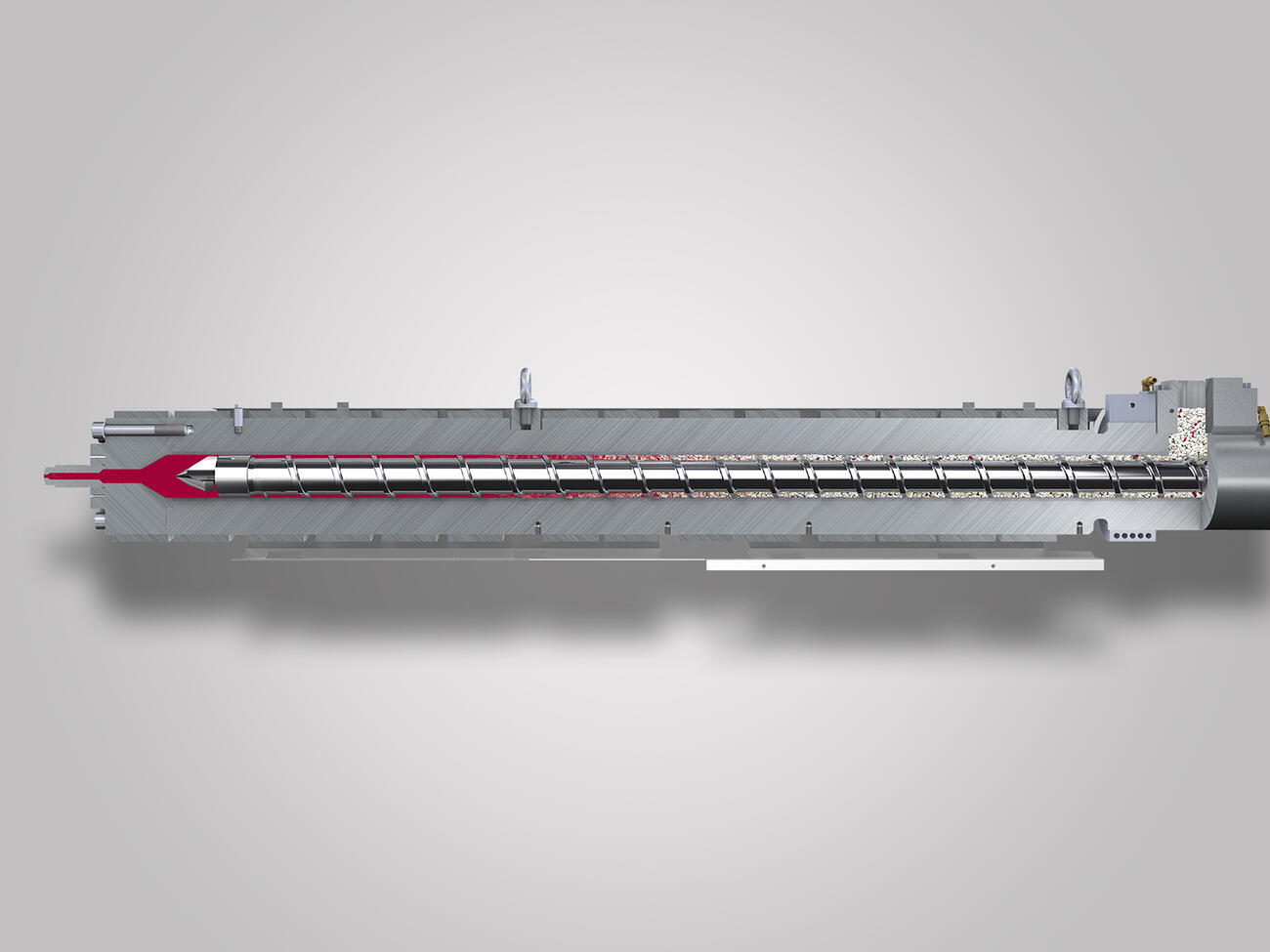

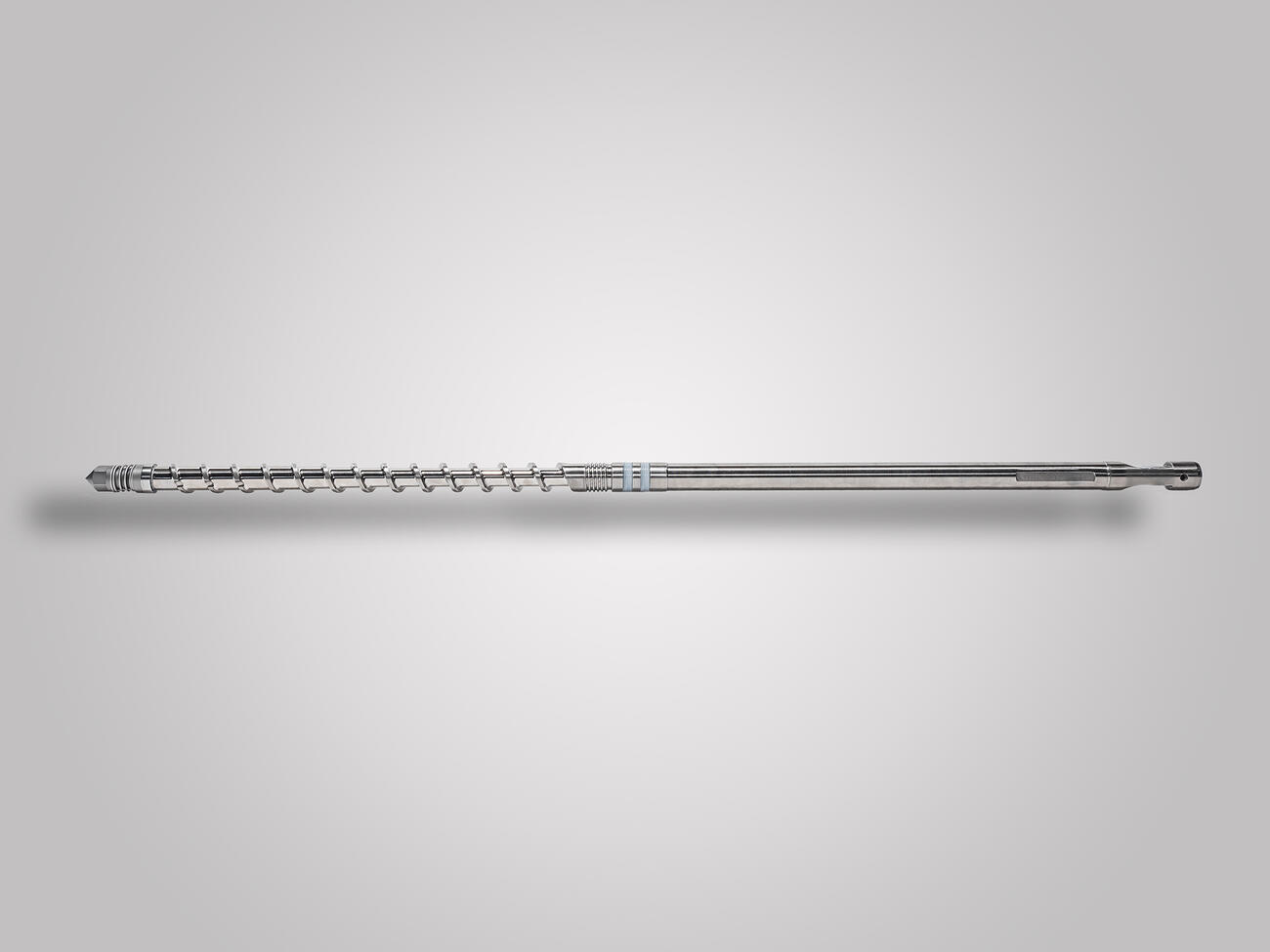

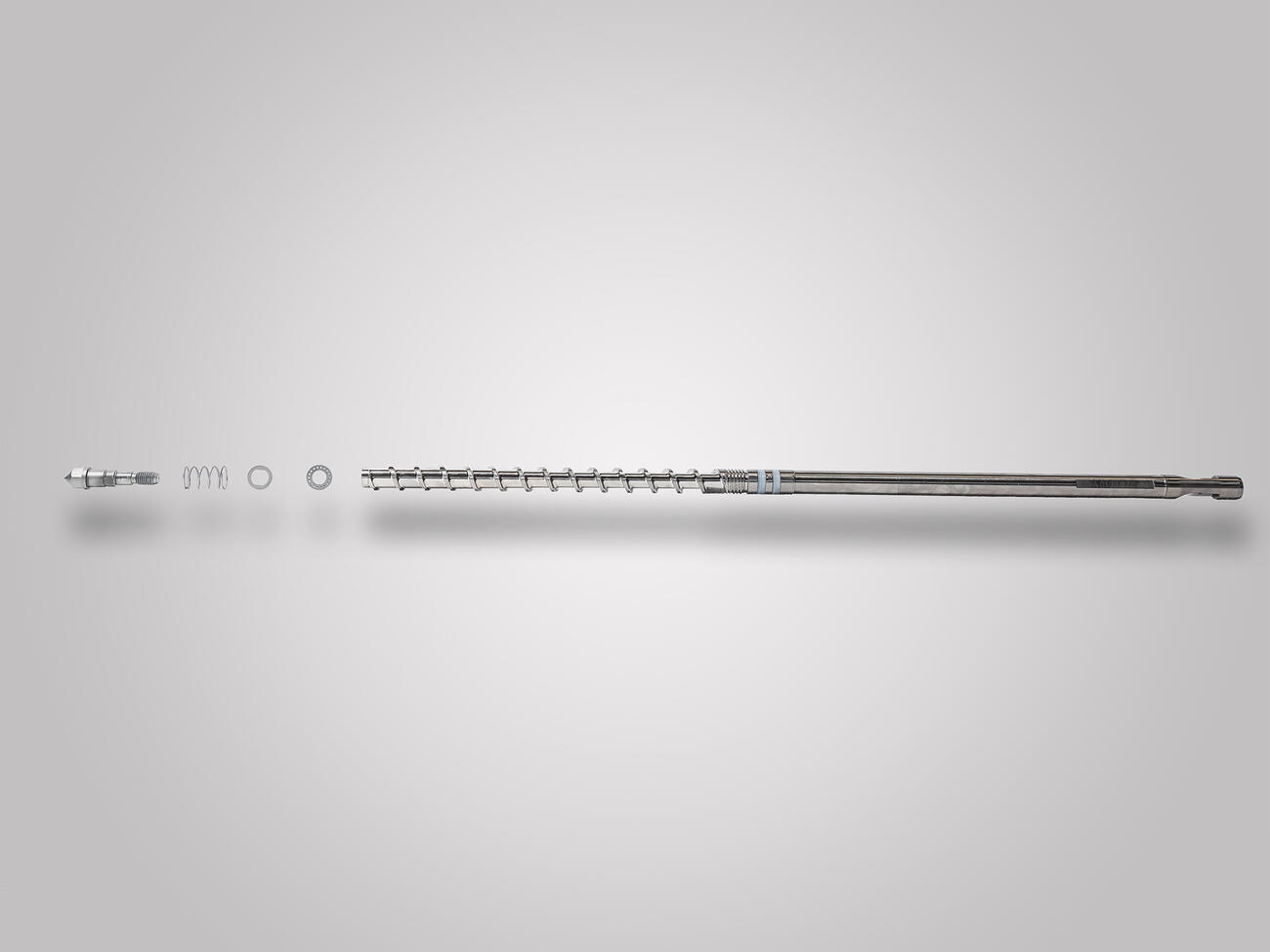

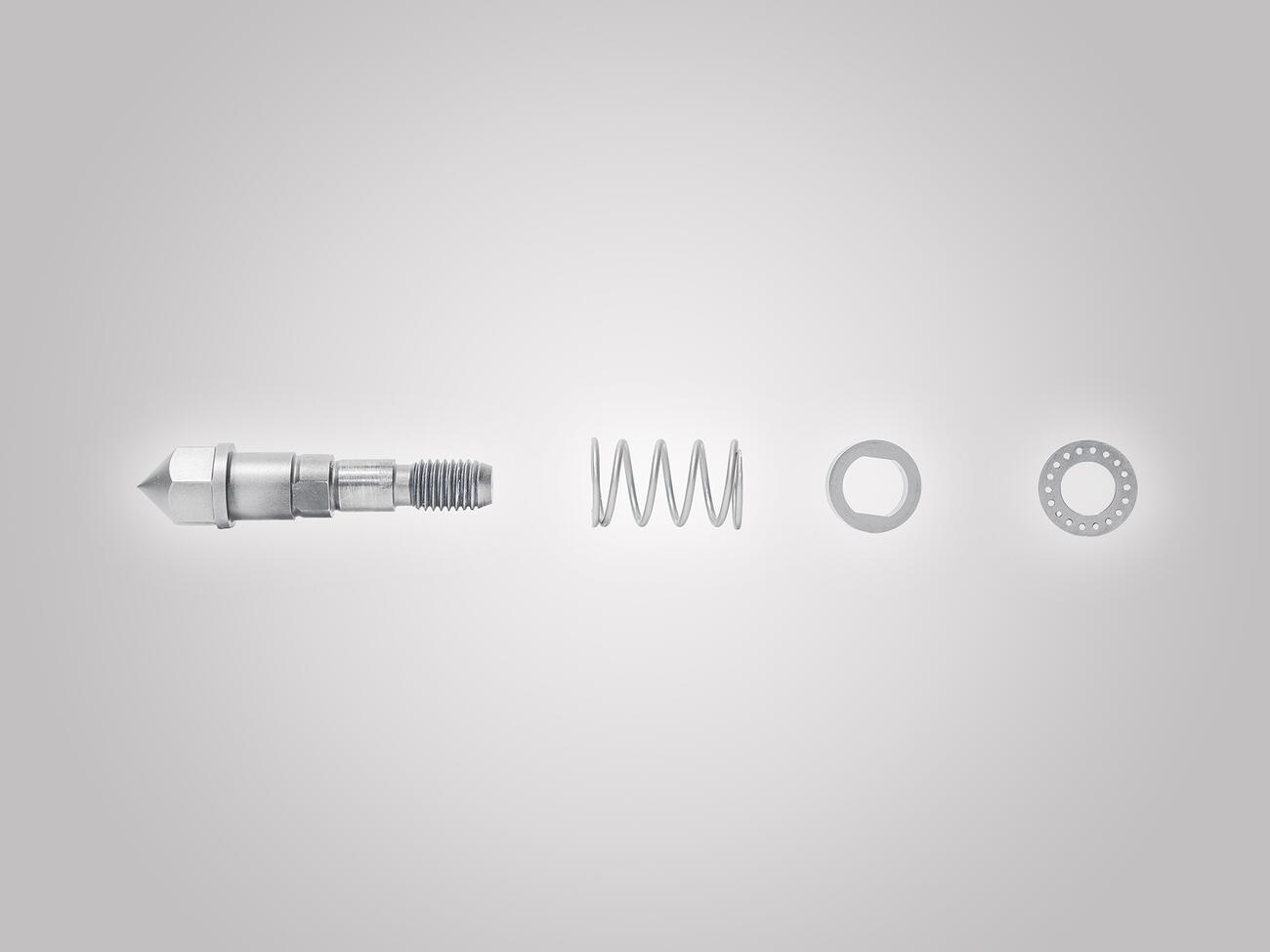

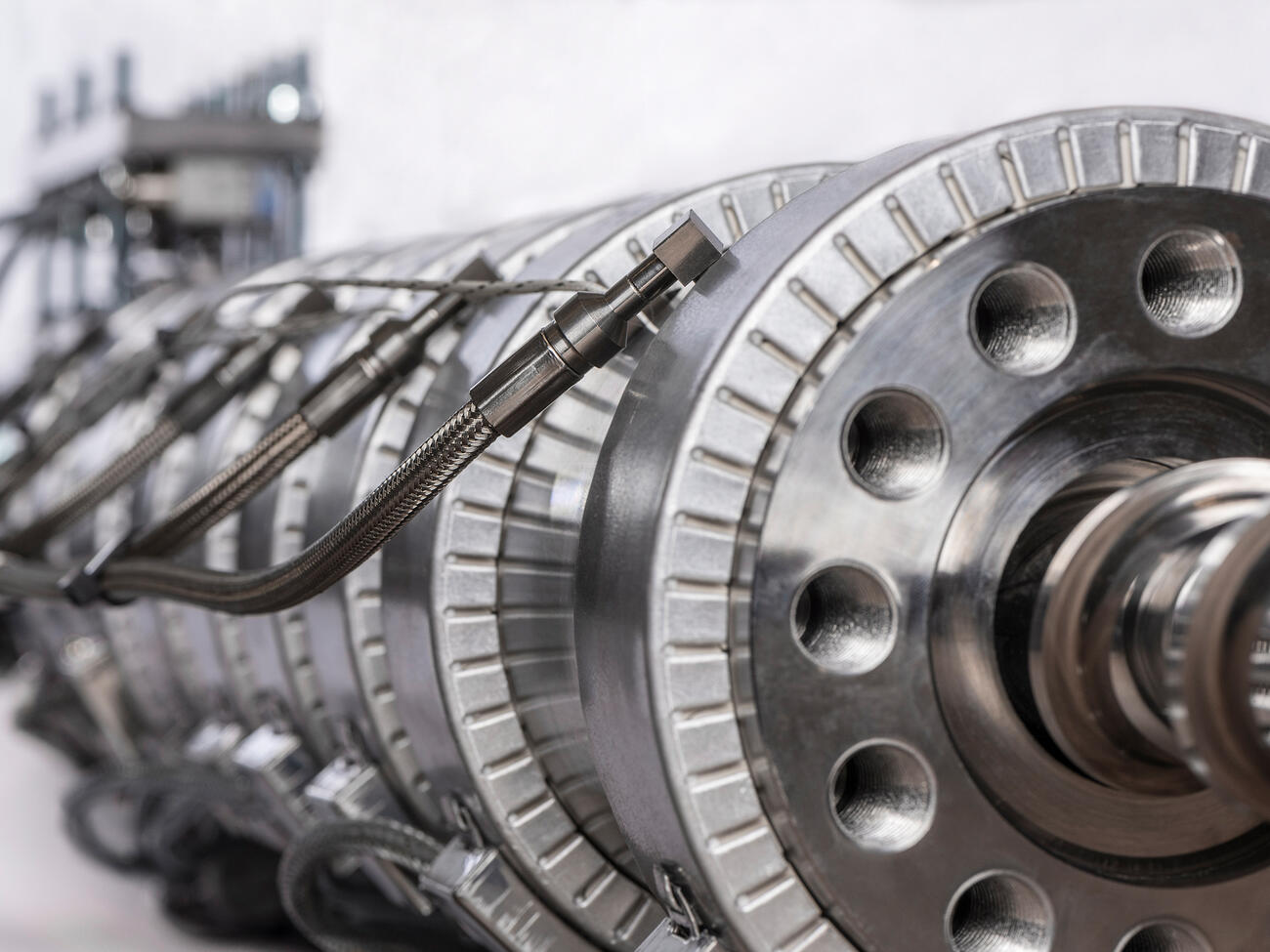

With a focus on cost-effectiveness, screws, barrels and non-return valves can be customized with regard to their plasticizing performance as well as load and application. For the plasticizing system components, high-quality steels – tailored for each application – are used. Customers who process high percentages of reinforcing fibers, highly corrosive polymers and their blends with additives, as well as duromers, rely on the material and geometry selection of WITTMANN BATTENFELD's experts. The result is a long service life thanks to the usage of high-quality materials and coatings as well as component geometries which were developed over many years of research.

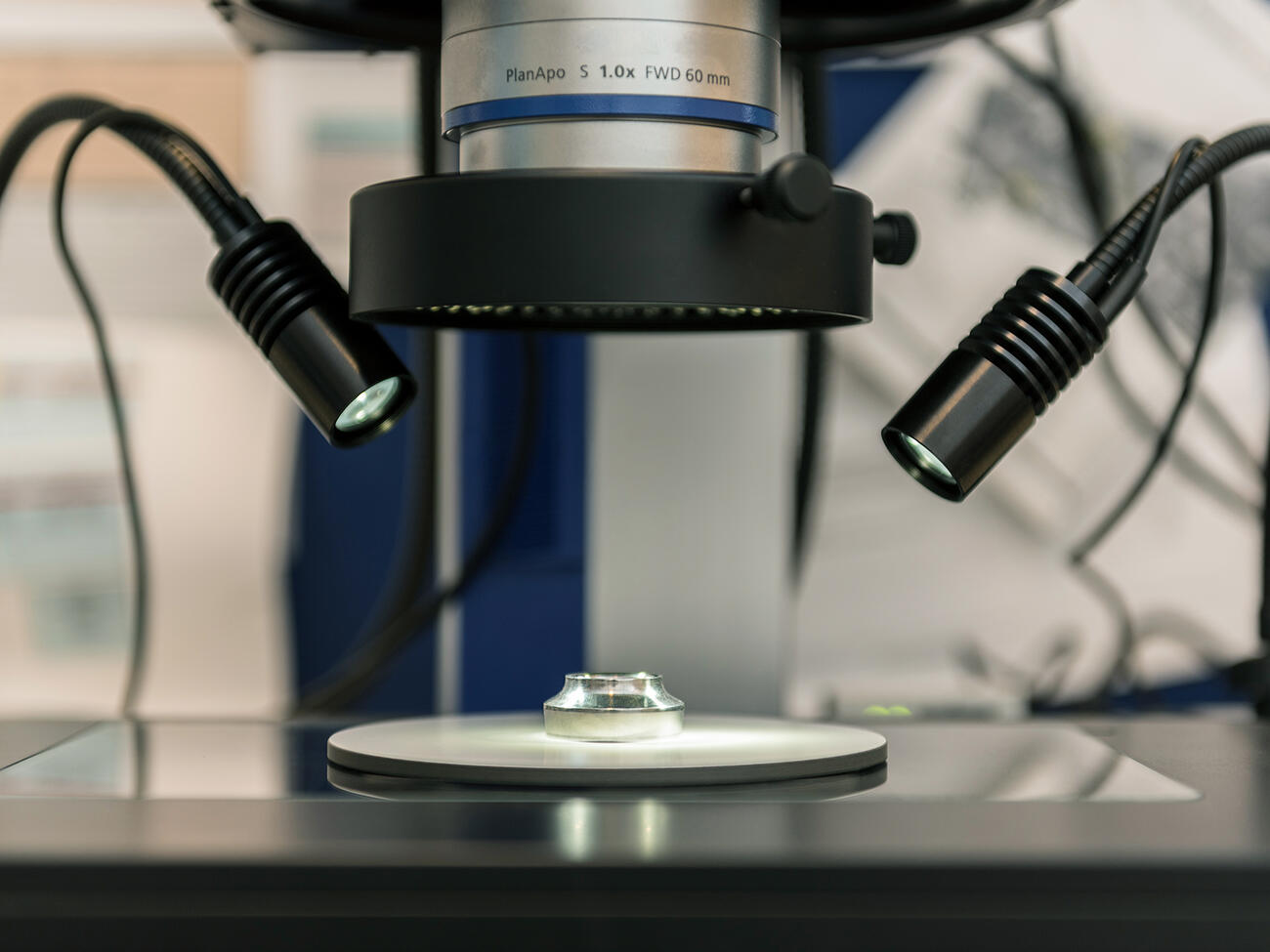

The ongoing development of geometries gives significant advantages when processing highly sensitive polymers in injection molding machine. The processing of crystal-clear plastics is highly dependent on the surface properties of the plasticizing components as well as fast and non-abrasive melting. For these applications, WITTMANN BATTENFELD provides its customers with components that combine maximum surface roughness with optimized screw geometry.

Standardized manufacturing processes and total quality control of all plasticizing components ensure a long product life. Development, engineering as well as in-house production of the components, and expert consultancy, all guarantee the customer a high level of supply security for the core components of the injection molding machine – completely in line with the "One-Stop-Shop" principle at WITTMANN BATTENFELD.

'Material and processing quality are crucial factors for the longevity of plasticizing components and ensure a high degree of planning reliability for our customers. That is why we place a special emphasis on them.'

Dipl.-Ing. Anton Oberradter, Materials Technology Development at WITTMANN BATTENFELD

Downloads