LSR applications for everyday products

LSR applications for everyday products

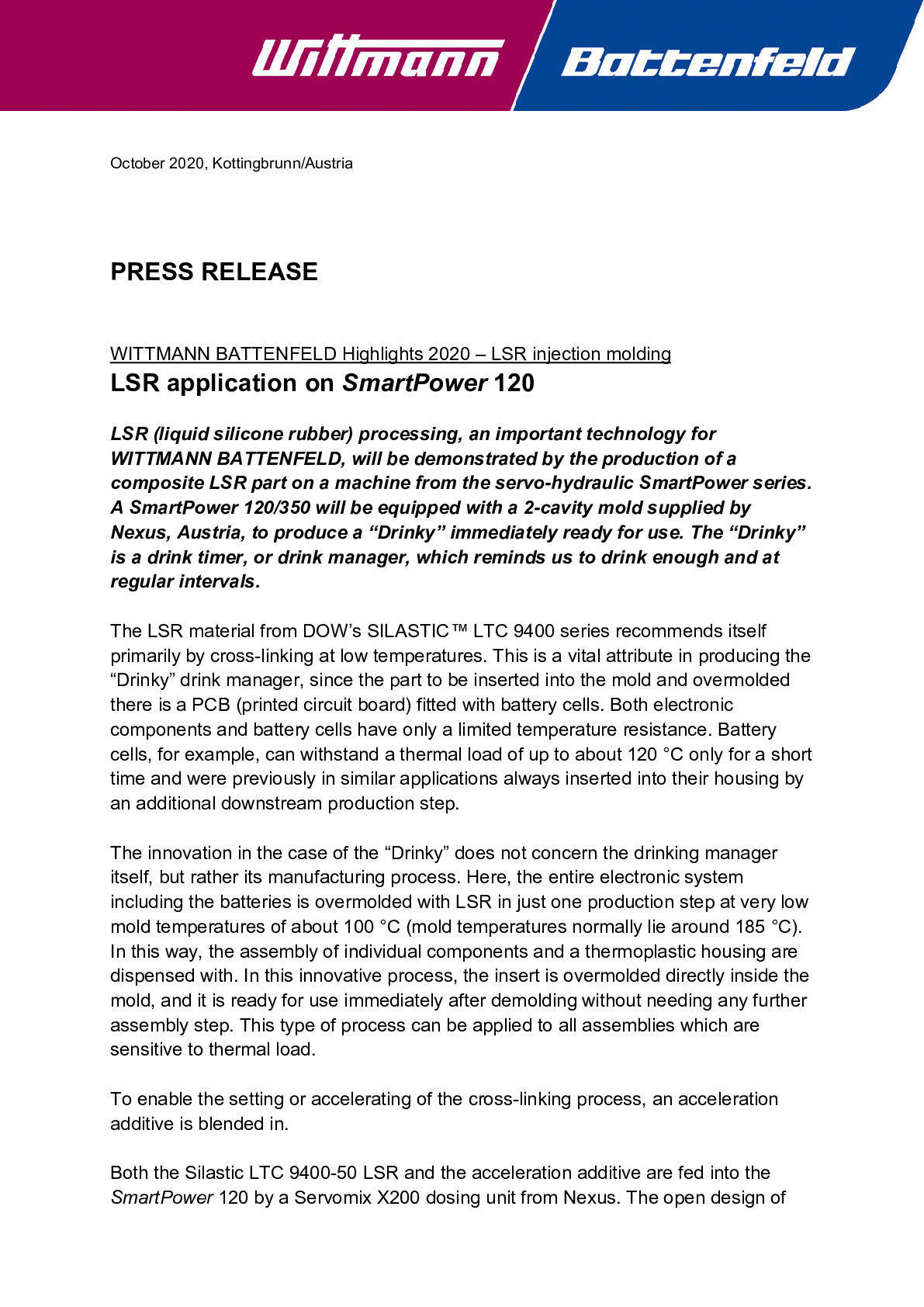

"Drinky" drink timer

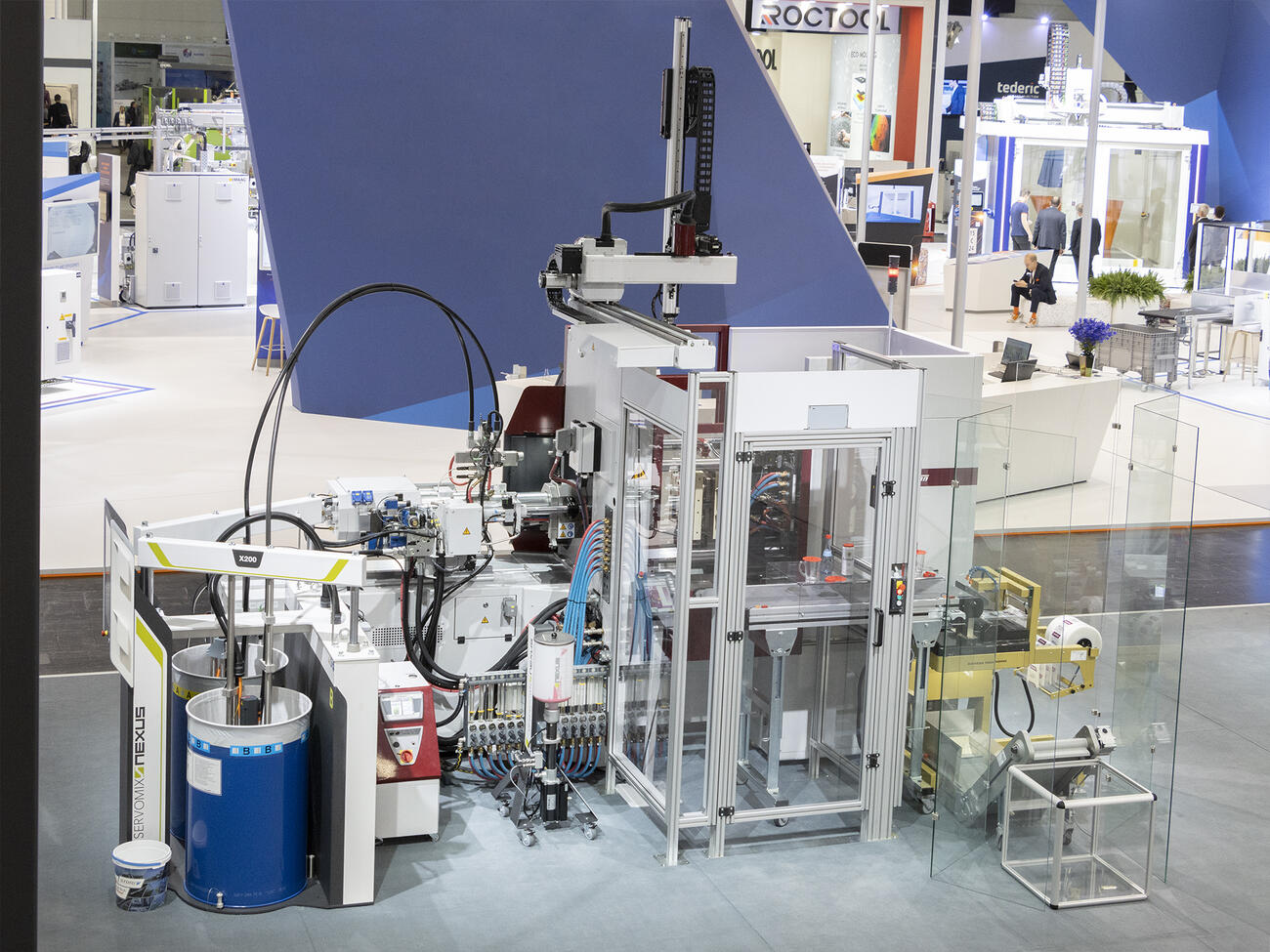

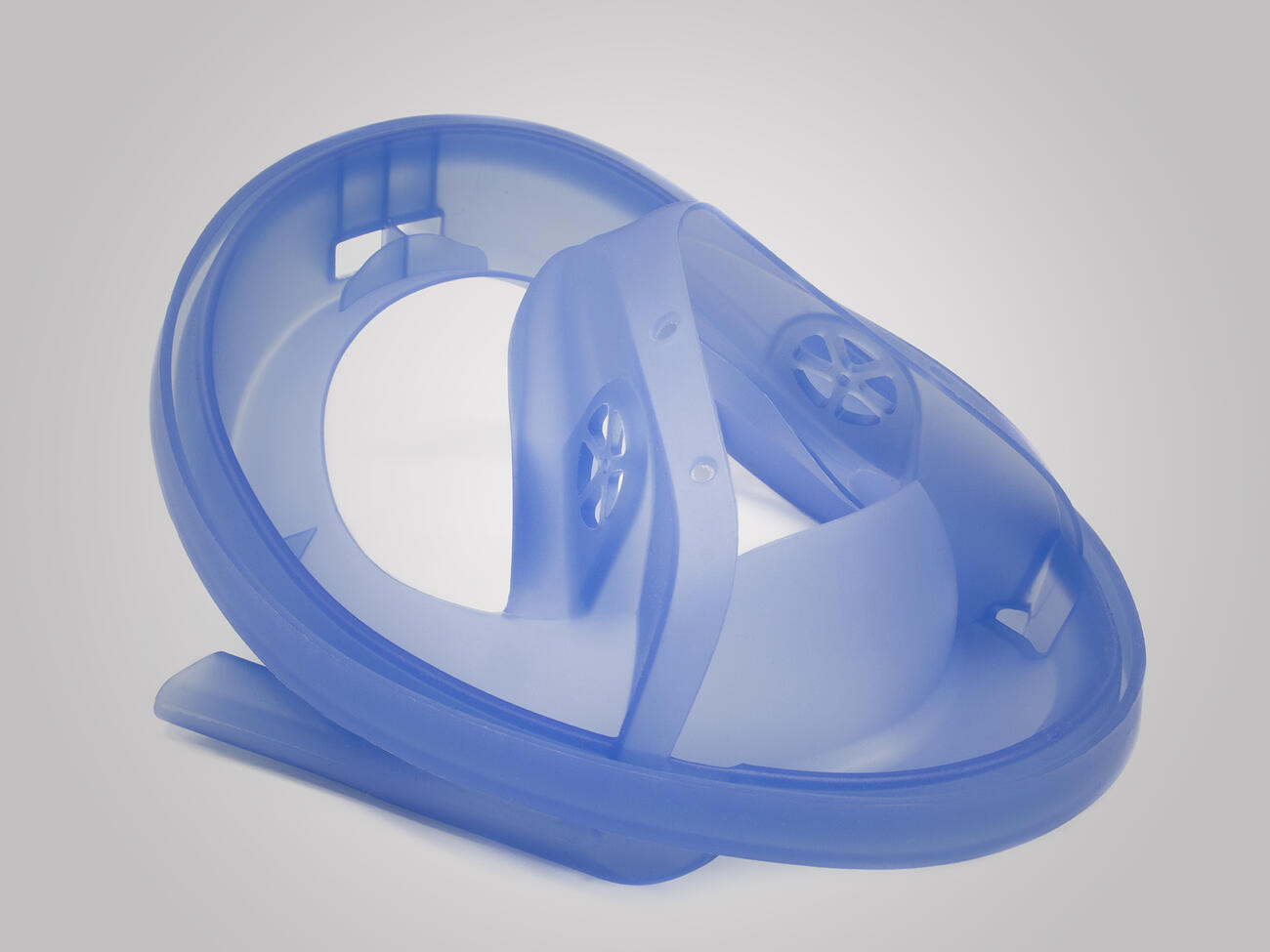

WITTMANN BATTENFELD LIM – Liquid Incetion Molding

LSR (liquid silicone rubber) processing, an important technology for WITTMANN BATTENFELD, will be demonstrated by the production of a composite LSR part on a machine from the servo-hydraulic SmartPower series. A SmartPower 120/350 will be equipped with a 2-cavity mold supplied by Nexus, Austria, to produce a “Drinky” immediately ready for use. The “Drinky” is a drink timer, or drink manager, which reminds us to drink enough and at regular intervals.

- Servo-hydraulic machine in LSR design

- Injection unit in open design for easy integration of the LSR dosing system

- Differential pressure measurement in the feed zone

- LSR dosing system with Servomix dosing unit with Euromap 82.3 (OPC-UA integration)

- Permanent monitoring and filtration of the cooling water for plasticizing unit and mold

Downloads