Producing decorated and functionalized surfaces

Producing decorated and functionalized surfaces

IMD/IML technologies

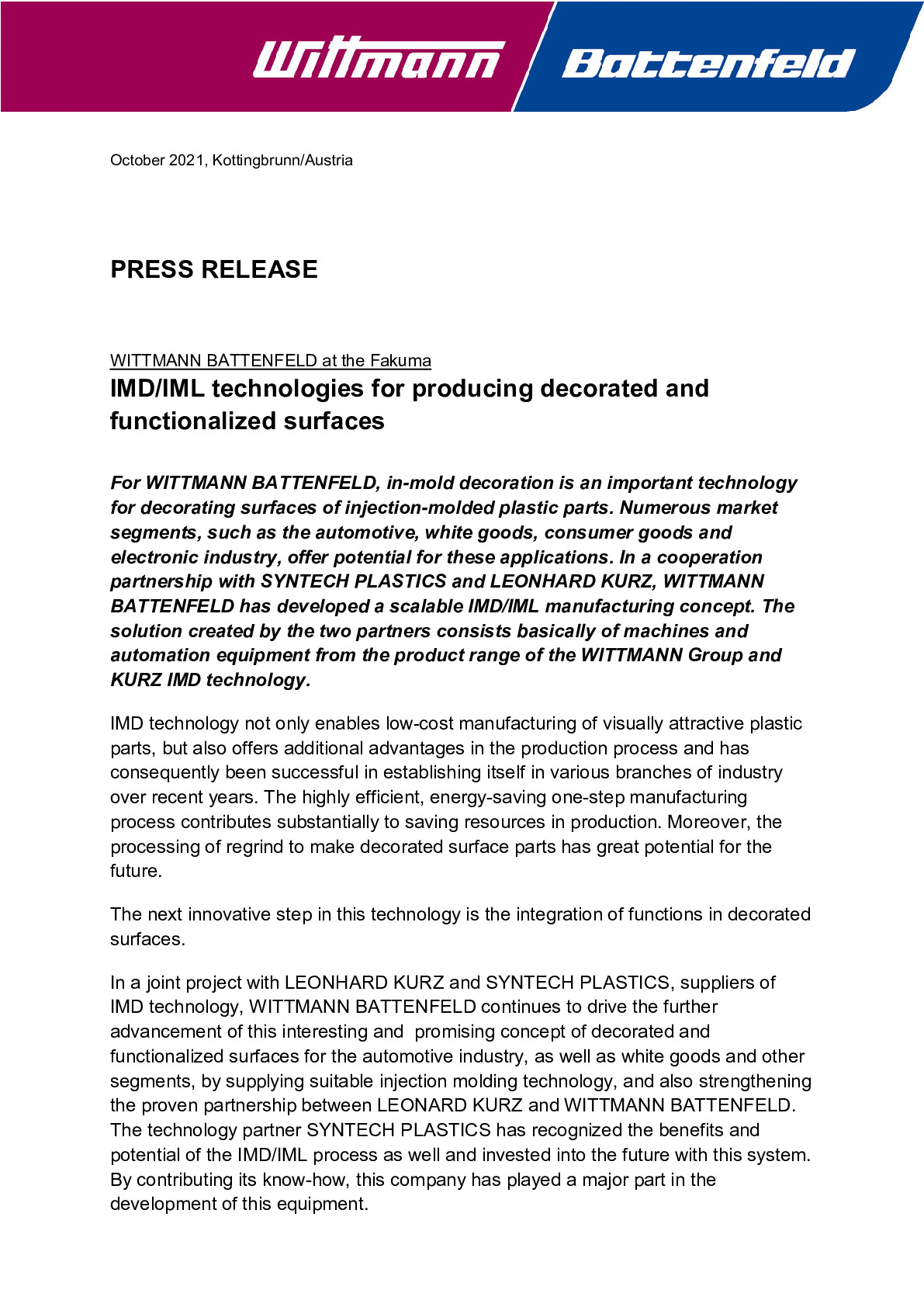

For WITTMANN BATTENFELD, in-mold decoration is an important technology for decorating surfaces of injection-molded plastic parts. Numerous market segments, such as the automotive, white goods, consumer goods and electronic industry, offer potential for these applications. In a cooperation partnership with SYNTECH PLASTICS and LEONHARD KURZ, WITTMANN BATTENFELD has developed a scalable IMD/IML manufacturing concept. The solution created by the two partners consists basically of machines and automation equipment from the product range of the WITTMANN Group and KURZ IMD technology.

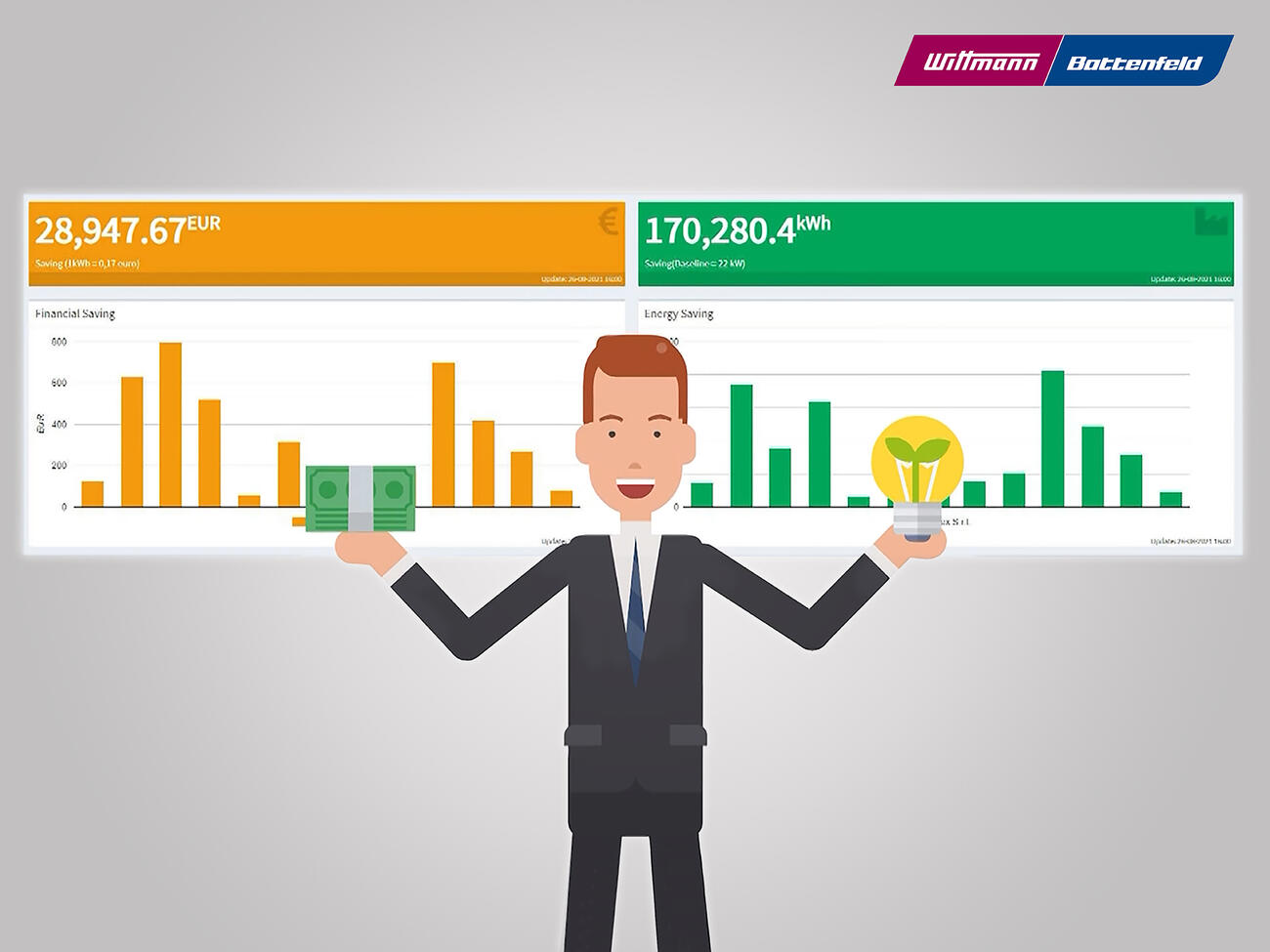

IMD technology not only enables low-cost manufacturing of visually attractive plastic parts, but also offers additional advantages in the production process and has consequently been successful in establishing itself in various branches of industry over recent years. The highly efficient, energy-saving one-step manufacturing process contributes substantially to saving resources in production. Moreover, the processing of regrind to make decorated surface parts has great potential for the future.

The next innovative step in this technology is the integration of functions in decorated surfaces.

In a joint project with LEONHARD KURZ and SYNTECH PLASTICS, suppliers of IMD technology, WITTMANN BATTENFELD continues to drive the further advancement of this interesting and promising concept of decorated and functionalized surfaces for the automotive industry, as well as white goods and other segments, by supplying suitable injection molding technology, and also strengthening the proven partnership between LEONARD KURZ and WITTMANN BATTENFELD. The technology partner SYNTECH PLASTICS has recognized the benefits and potential of the IMD/IML process as well and invested into the future with this system. By contributing its know-how, this company has played a major part in the development of this equipment.

Downloads