FIT FOR ENERGY

FIT FOR ENERGY

Detect energy saving potentials

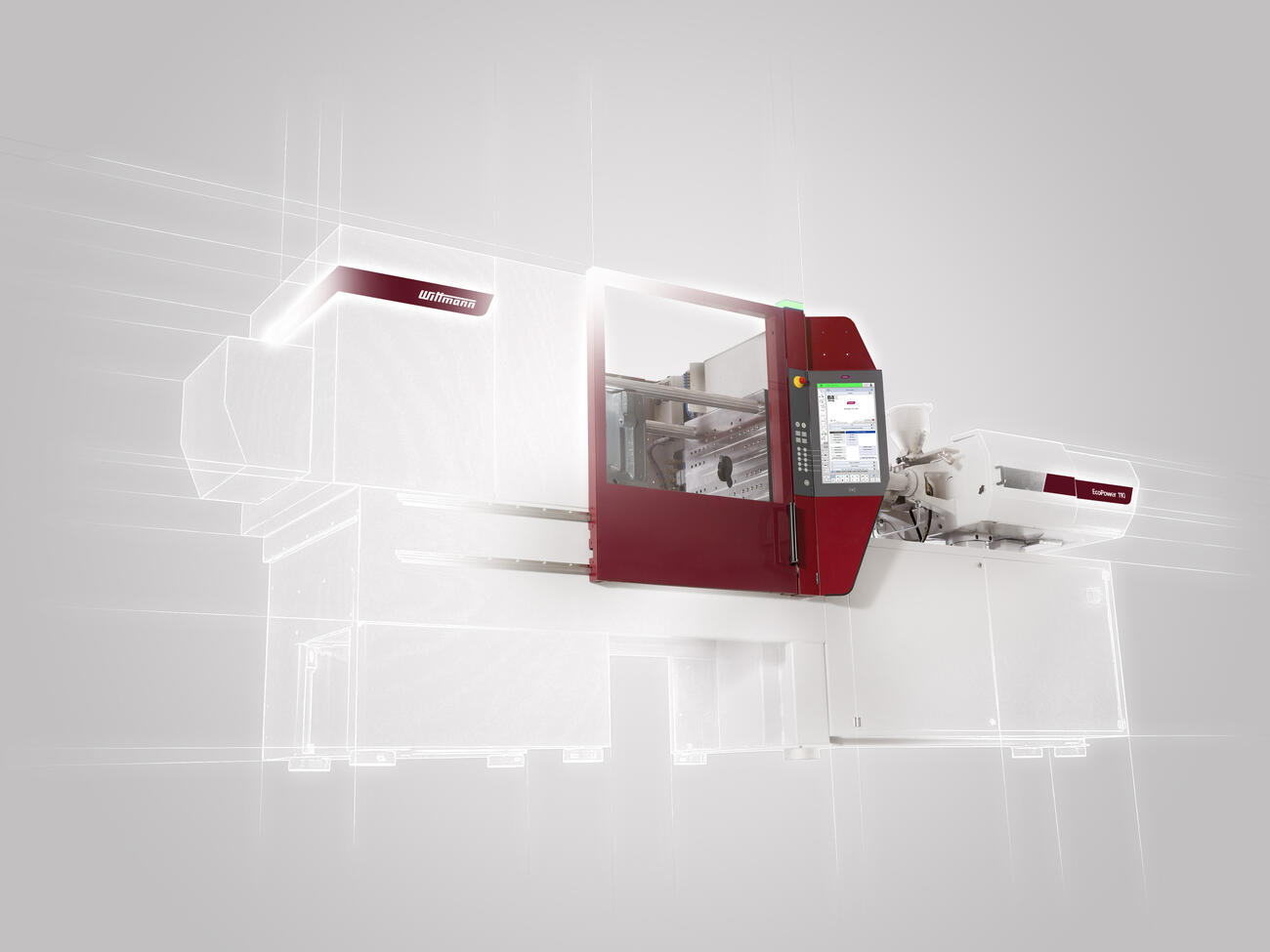

WITTMANN BATTENFELD is presenting to Fakuma visitors its service packages to detect energy savings potentials in the injection molding process at booth No. 1204 in Hall B1.

When it comes to saving energy, the question is not if, but how efficient actions to save energy can be implemented most effectively. With FIT FOR ENERGY, WITTMANN BATTENFELD supports plastics processors in finding and realizing the appropriate measures.

To identify savings potentials, it is important to proceed in a systematic way. For this purpose, WITTMANN BATTENFELD has put together three service packages. The special point here: this range not only functions with the company’s own machines, robots and auxiliary appliances, but also with products of other brands. The company takes a comprehensive approach and focuses on its customers’ entire range of machinery and equipment.

Transparency across all energy consumers

Transparency is the first consideration: with the entry-level package, the energy consumption of each injection molding machine is measured, calculated and recorded according to Euromap 60.2. The second, extended package goes a step further by covering the entire production cell, including all auxiliaries in the energy measurement. On the basis of the data collected from the injection molding machine and the auxiliaries, including the consumption of cooling water and compressed air as well, the existing potentials for saving energy are revealed. Finally, the premium package also includes the implementation of energy efficiency measures. Across the entire production cell, the energy consumptions are measured, analyzed, and then the remedial actions decided on jointly with the processor are started. The package also includes a final measurement to visualize the success.

The three packages are coordinated with each other. Whoever starts by choosing the entry-level or the extended package can ramp up their consultancy scope to that of the next larger package at any time.

Everything from a single source from energy measurement to grant applications

WITTMANN has consistently invested in the FIT FOR ENERGY program. In items such as the measurement and analyzing equipment. Moreover, the energy analysis tool IMAGOxt has been developed, which is able to collect and analyze energy data from individual machines right up to entire production floors.

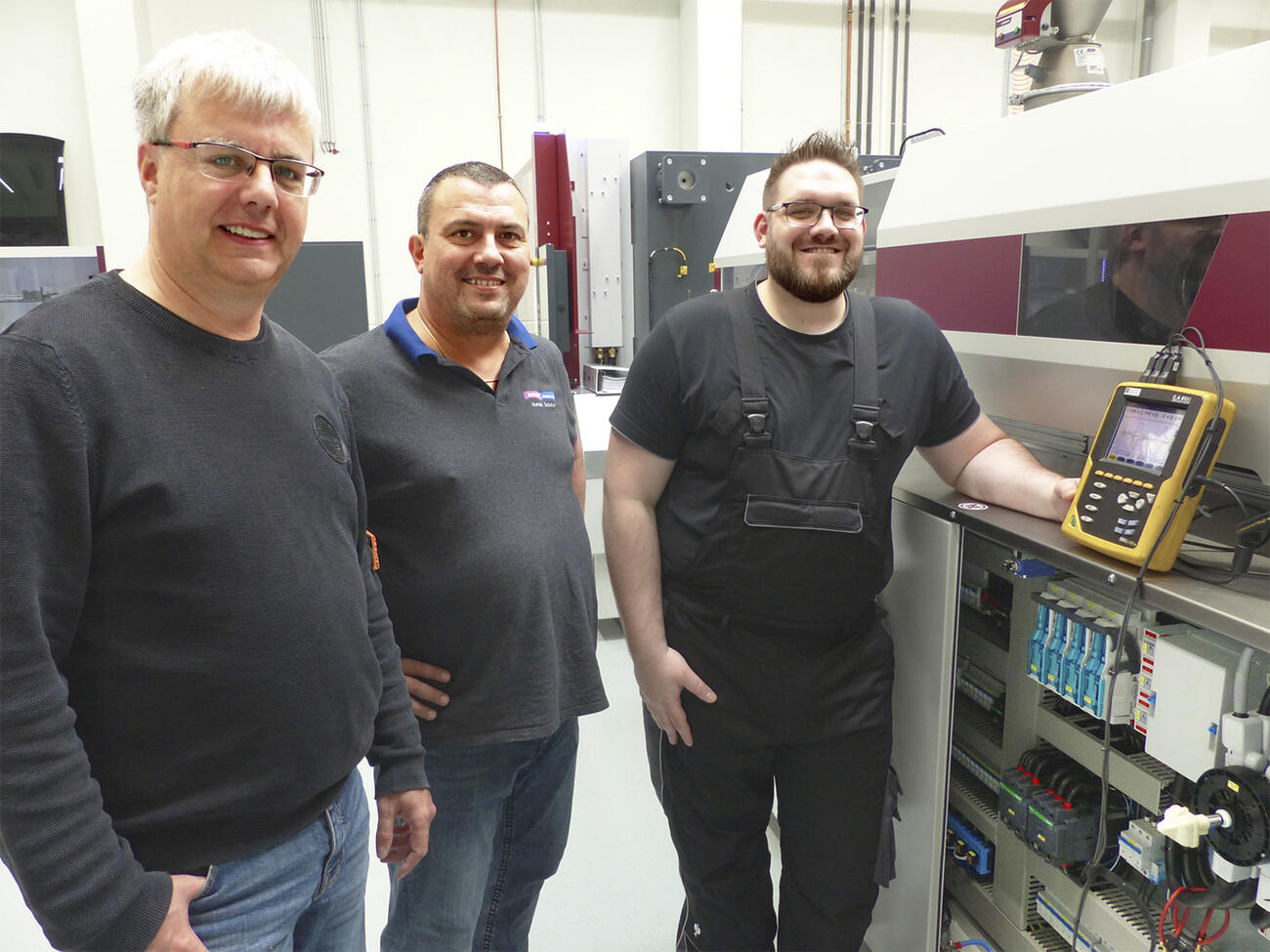

The personnel have also received consistent advanced training for the new consulting tasks. Experienced process and service engineers with an in-depth understanding of all injection molding processes stand ready to assist processors with energy measurement, analyses and consultancy. As a system supplier with a high innovative strength of its own in the areas of injection molding machines, automation, materials handling, temperature control and digitization, the WITTMANN Group covers the entire portfolio of injection molding products. No other supplier on the market can provide a portfolio of similar scope.

By way of close partnerships with energy consultants, primarily in Germany, the WITTMANN BATTENFELD experts have also acquired extensive knowledge about investment promotion options. Successful joint launching of grant applications has long been an integral part of its sales work.

At WITTMANN, conservation of resources takes center stage in all new developments and improvements – in its own production plants as well as in all customer projects. Processors benefit from the individual counseling and flexible implementation. There is no more effective way to achieve energy efficiency.

Energy measurement

At the Fakuma, an energy measurement will be carried out on all machines exhibited at the booth, using the IMAGOxt software, in addition to presenting the service packages mentioned above. The software provides a scalable display and visualization of the connected machines’ and appliances’ energy consumptions. The program also calculates directly the CO2 footprint plus any energy savings already achieved. All calculated values can be saved in reports and thus remain available for long-term analyses. The IMAGOxt program is a certified product according to DIN ISO 50 001. Consequently, the investment costs are eligible for funding in Germany.

Downloads