Vacuum Loaders

Vacuum Loaders

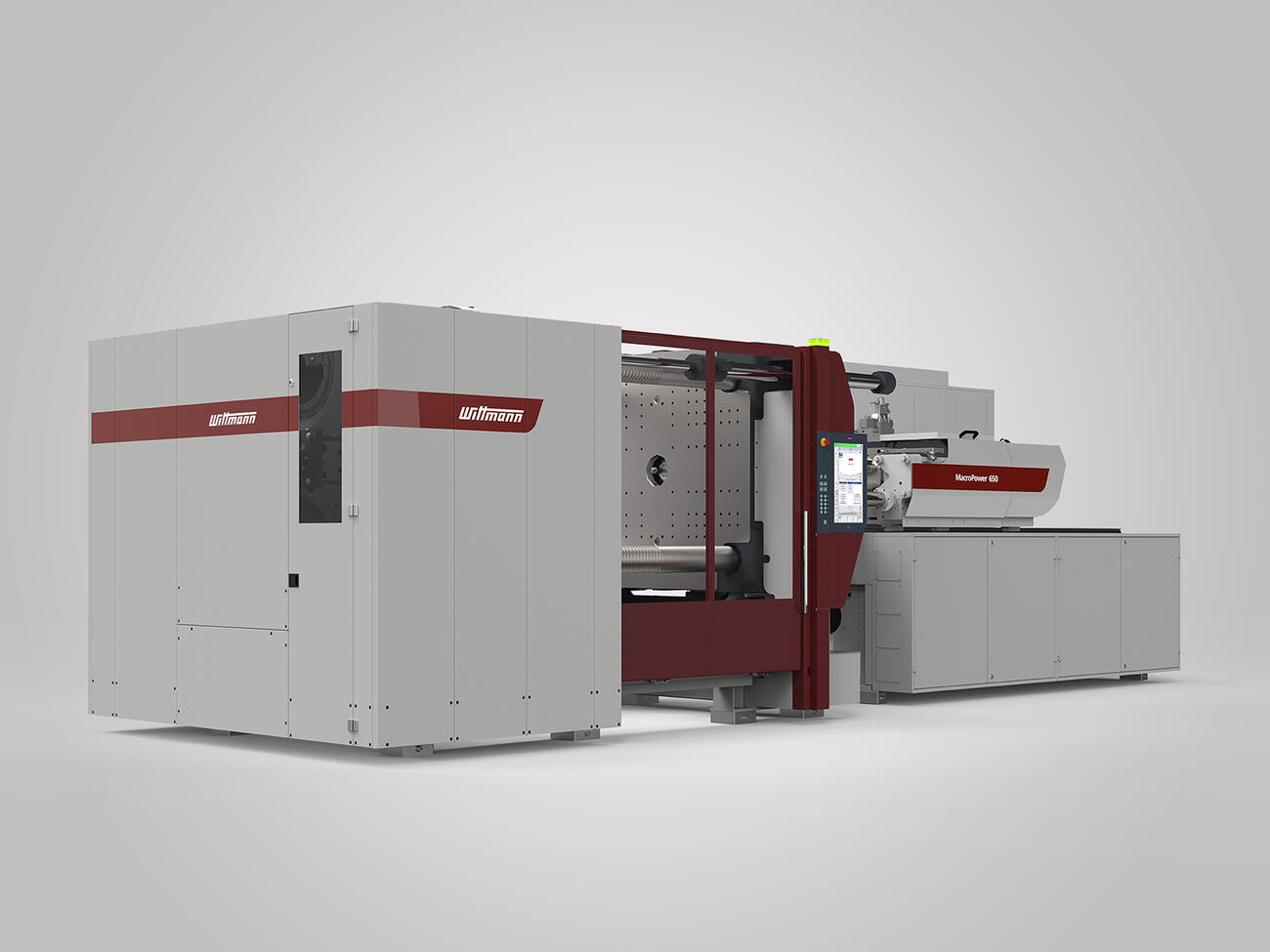

Conveying Systems for Plastics Processing Plants

WITTMANN Material Loaders and Conveying Units

Feedmax single and central material loaders, made from stainless steel, conveying material pricisely and securely. WITTMANN network controls are fit for connecting up to 320 system components.

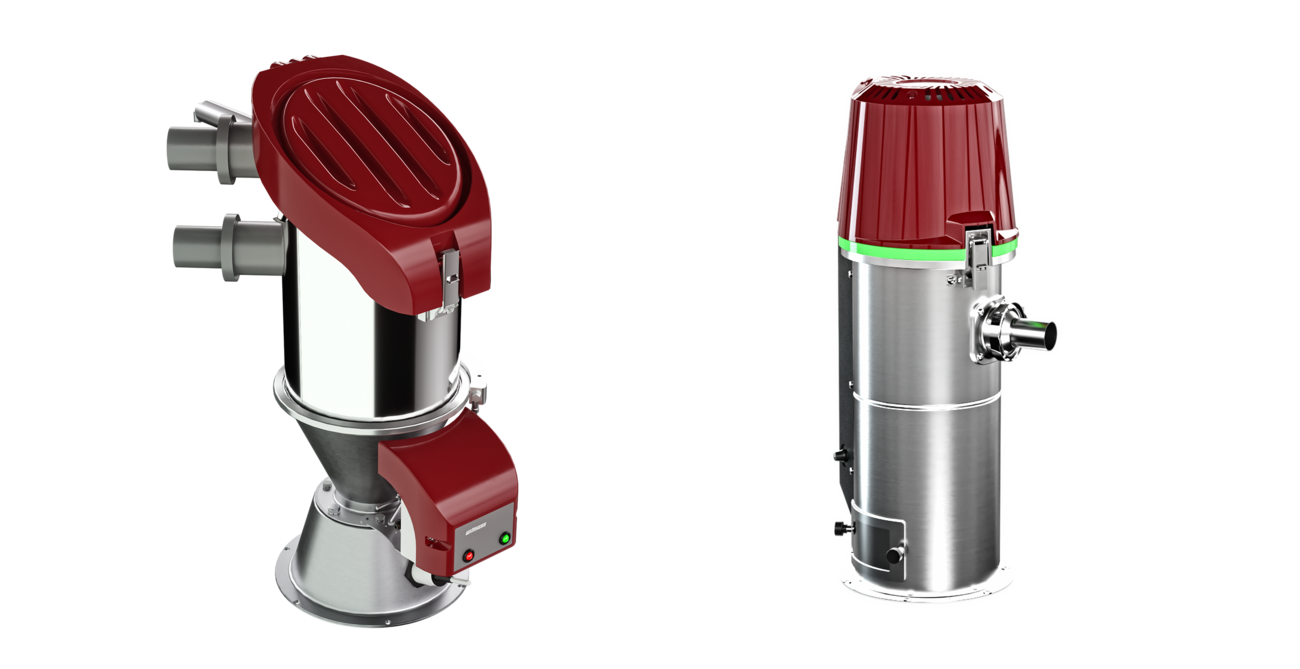

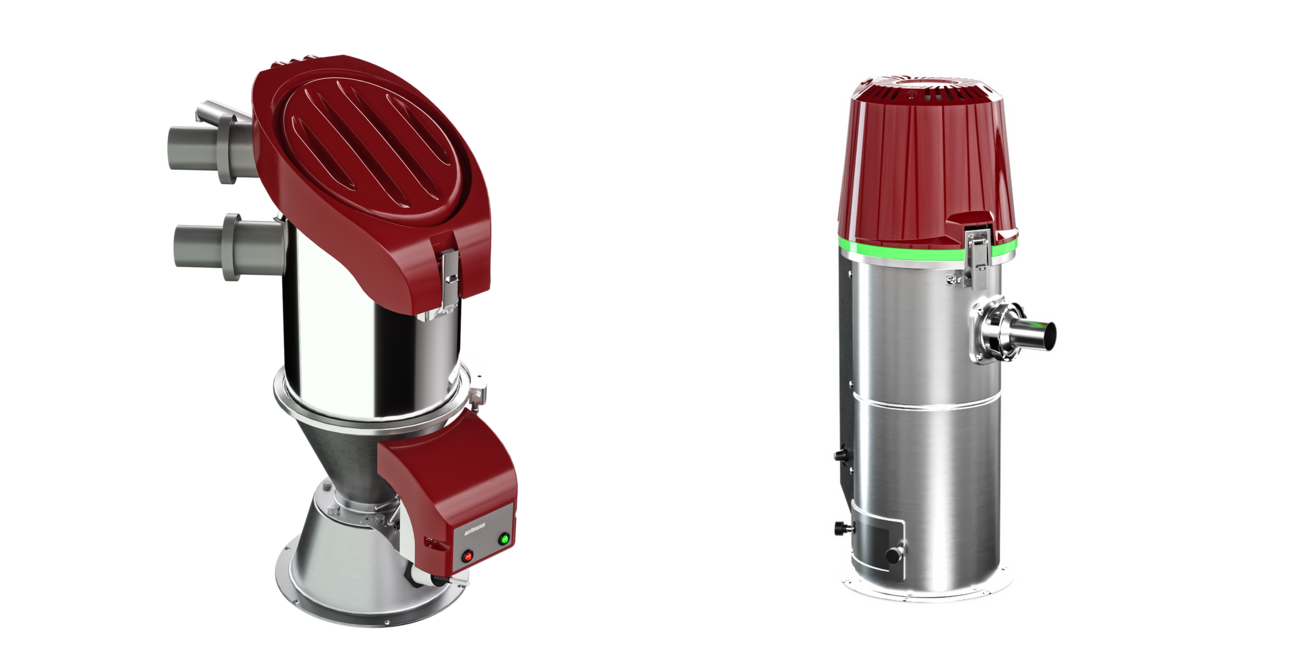

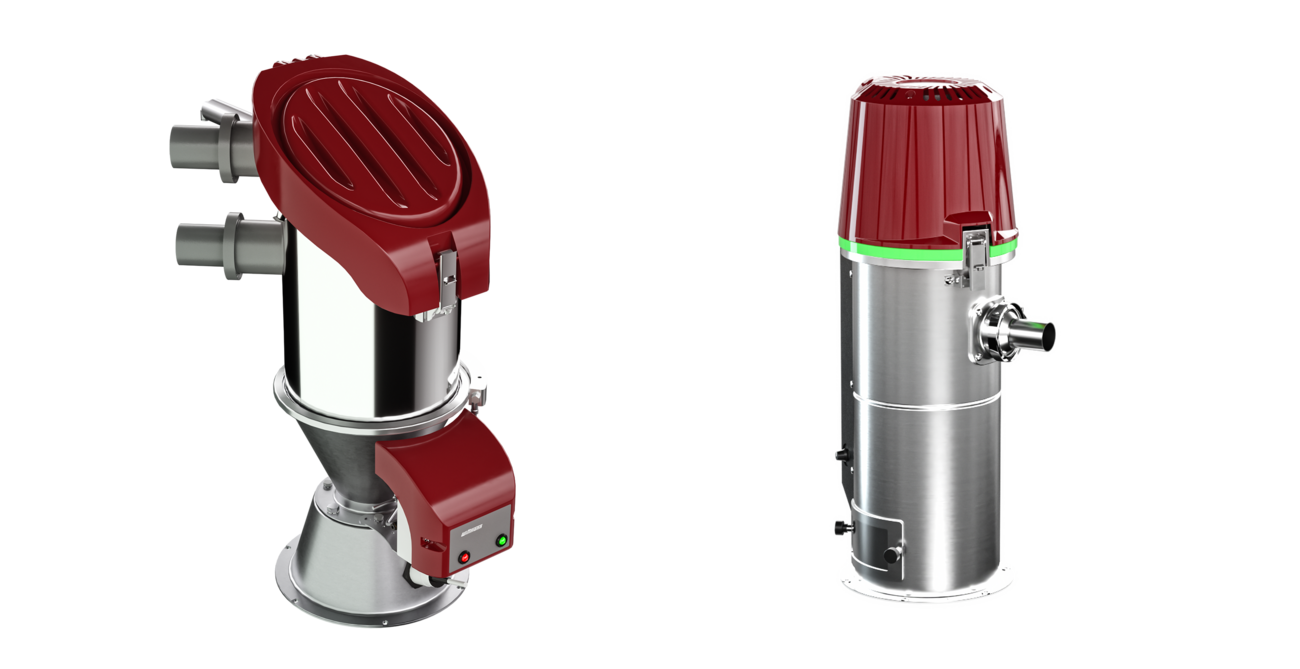

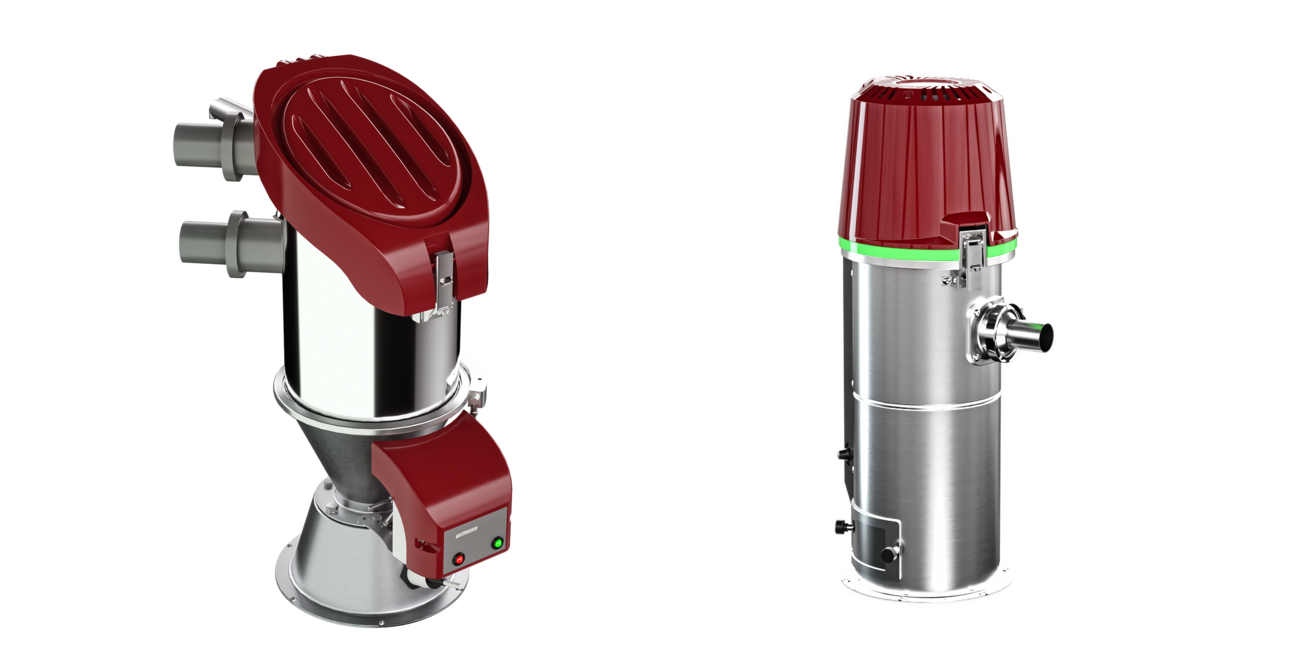

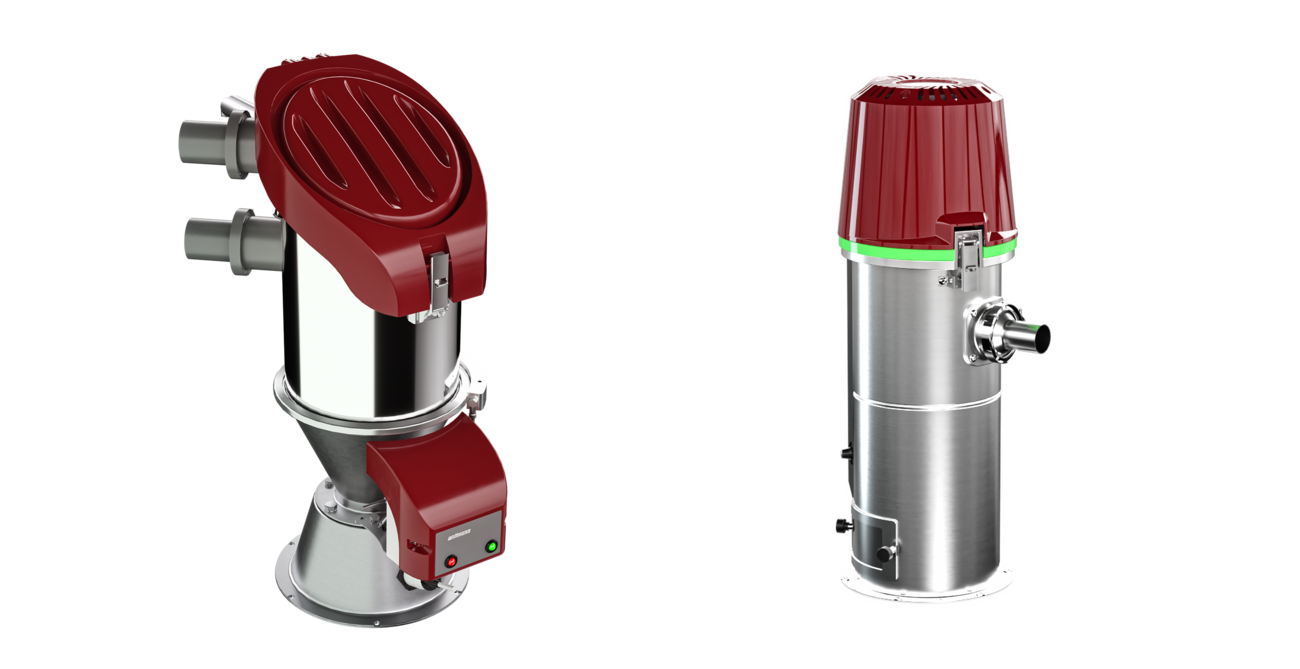

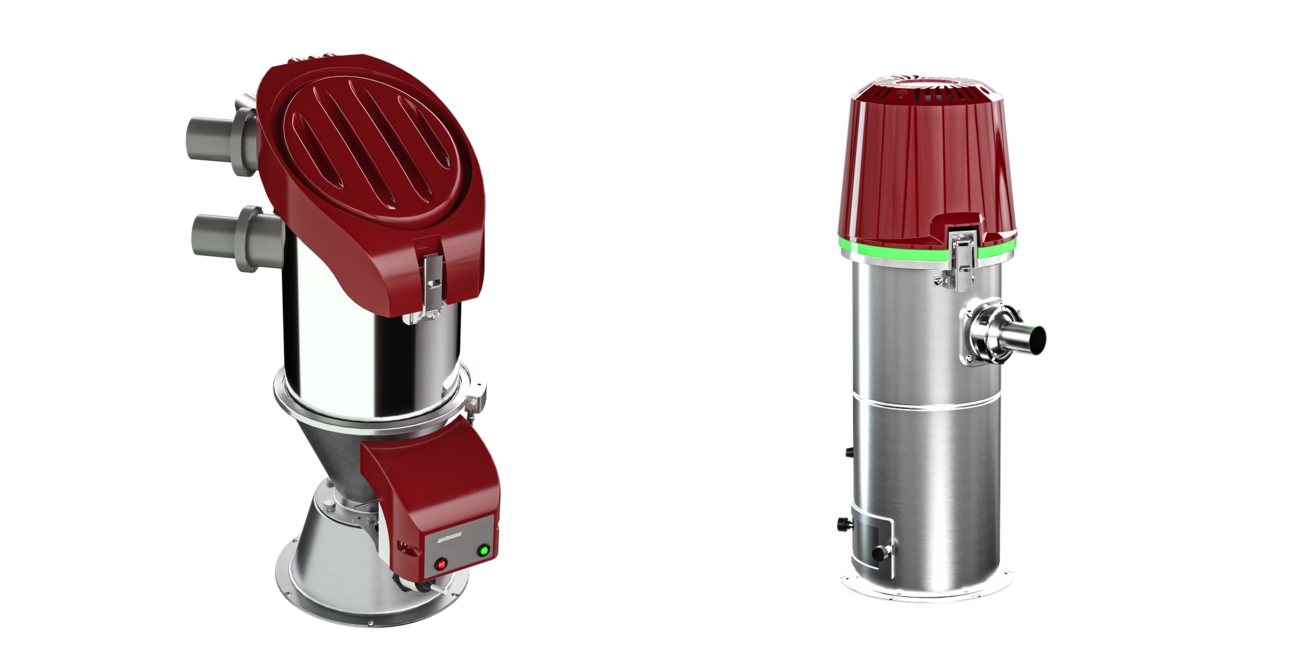

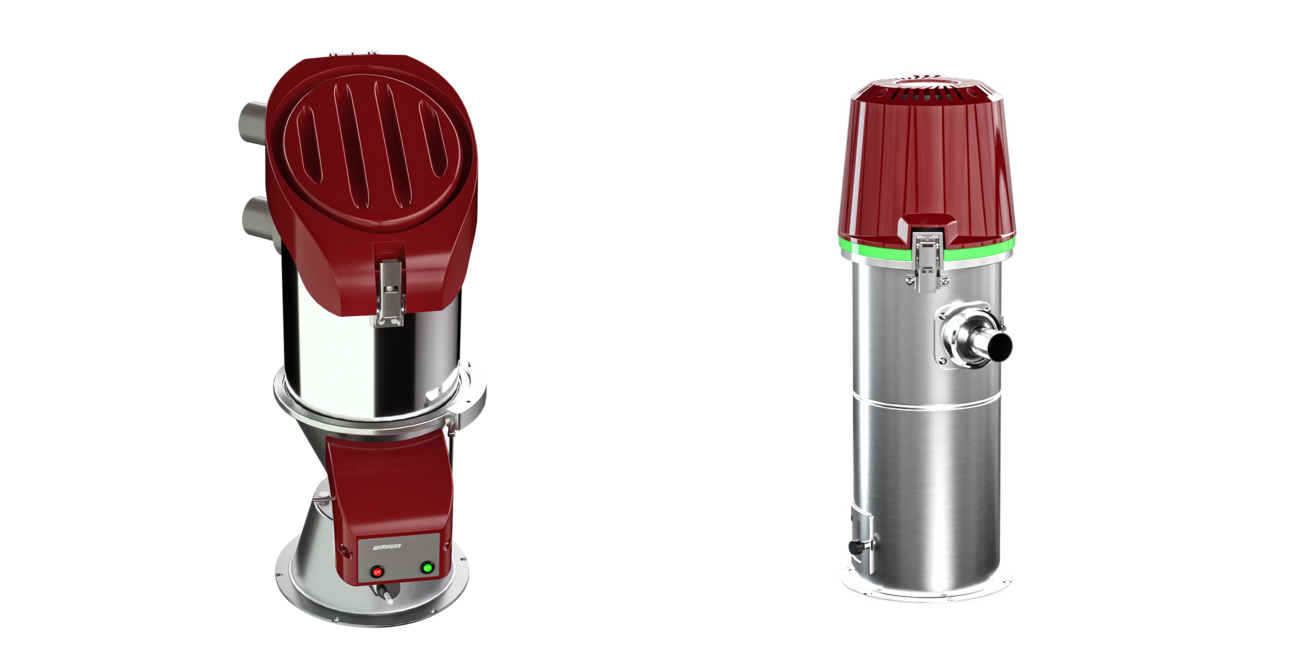

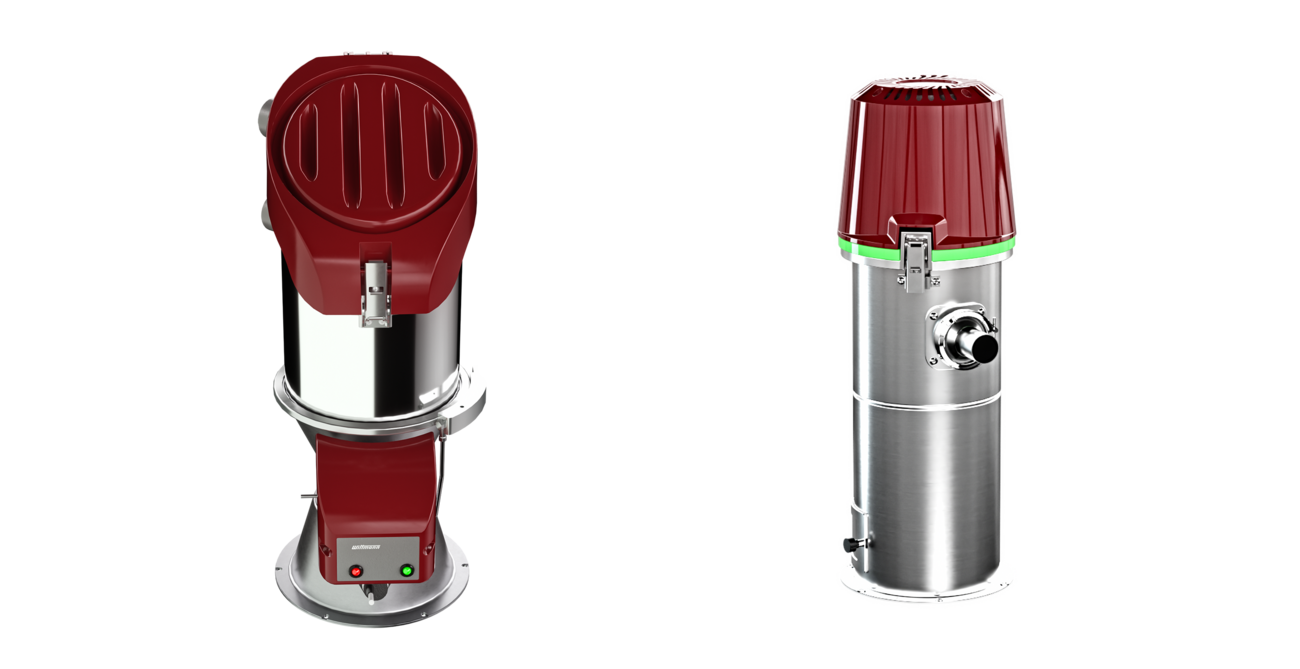

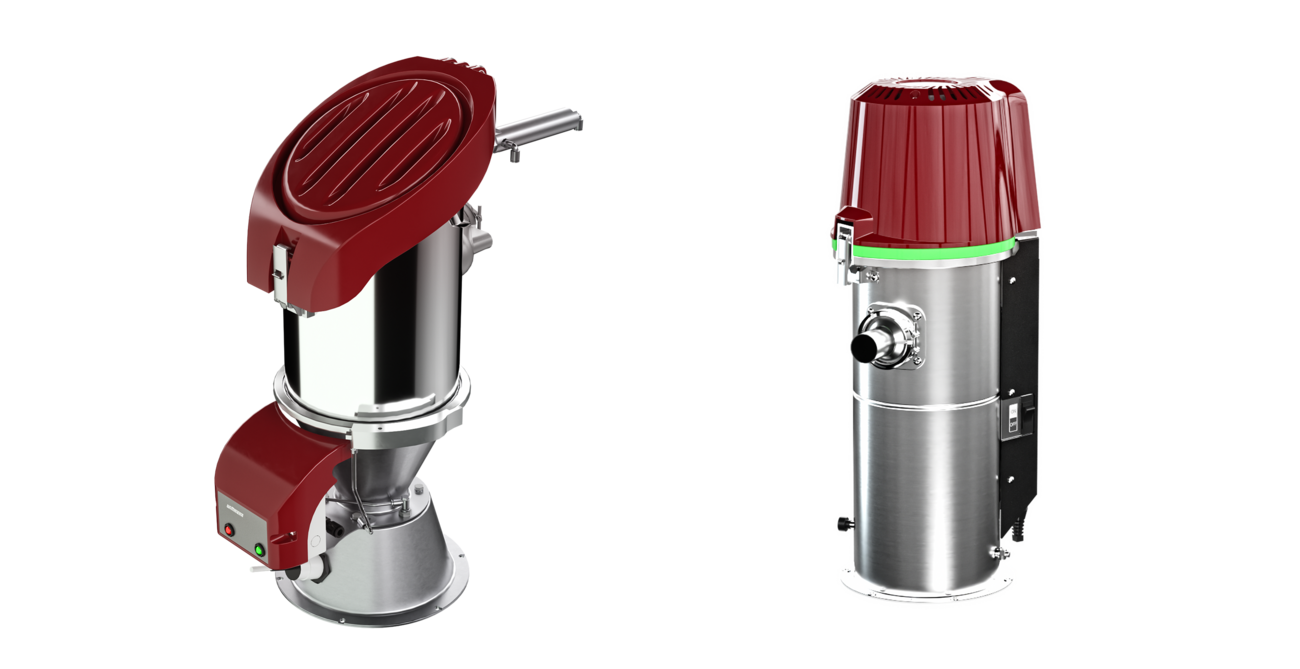

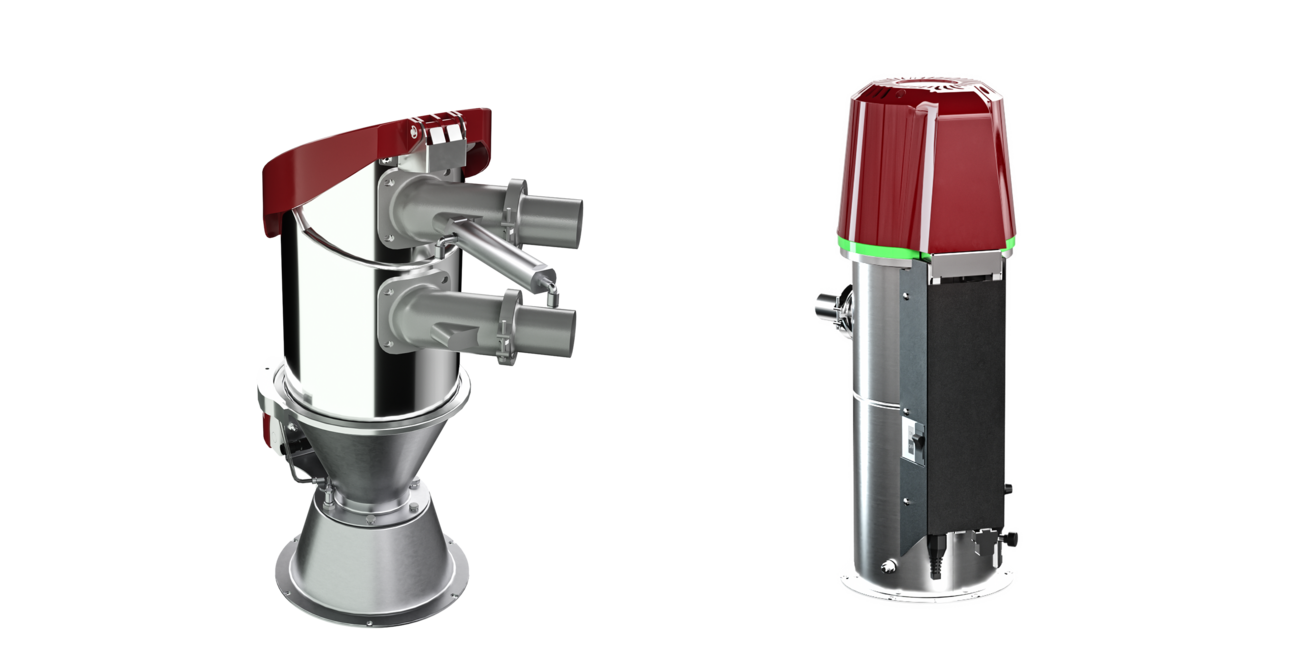

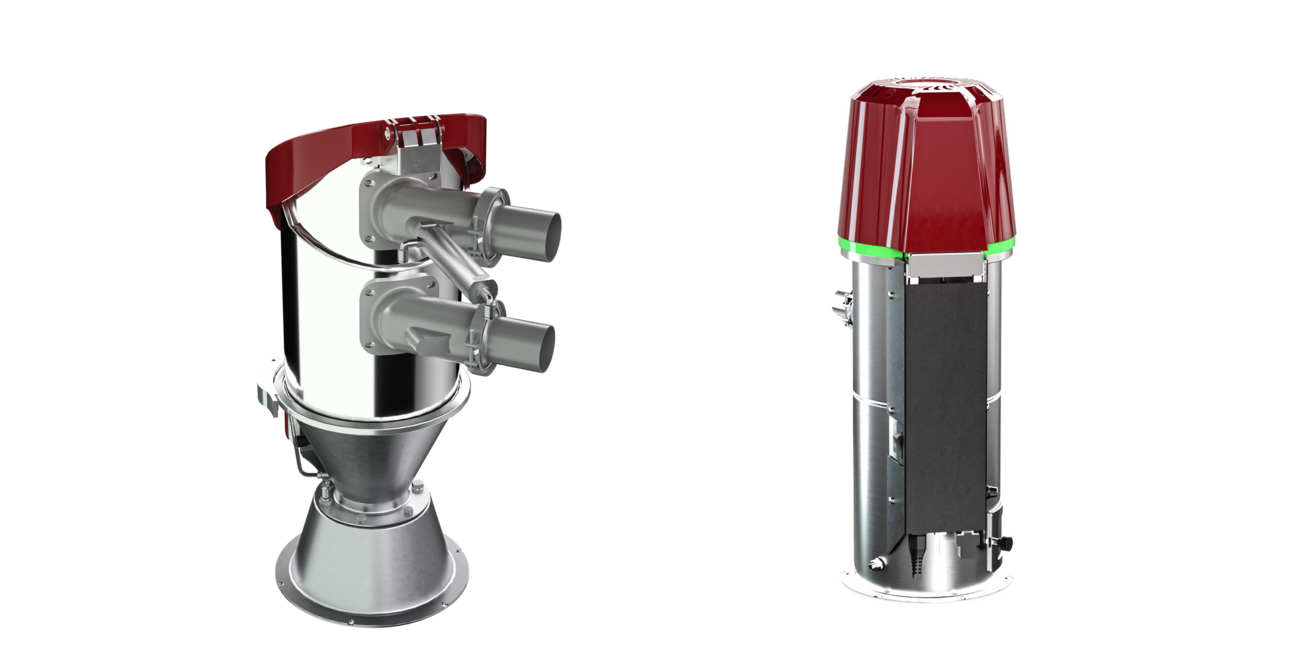

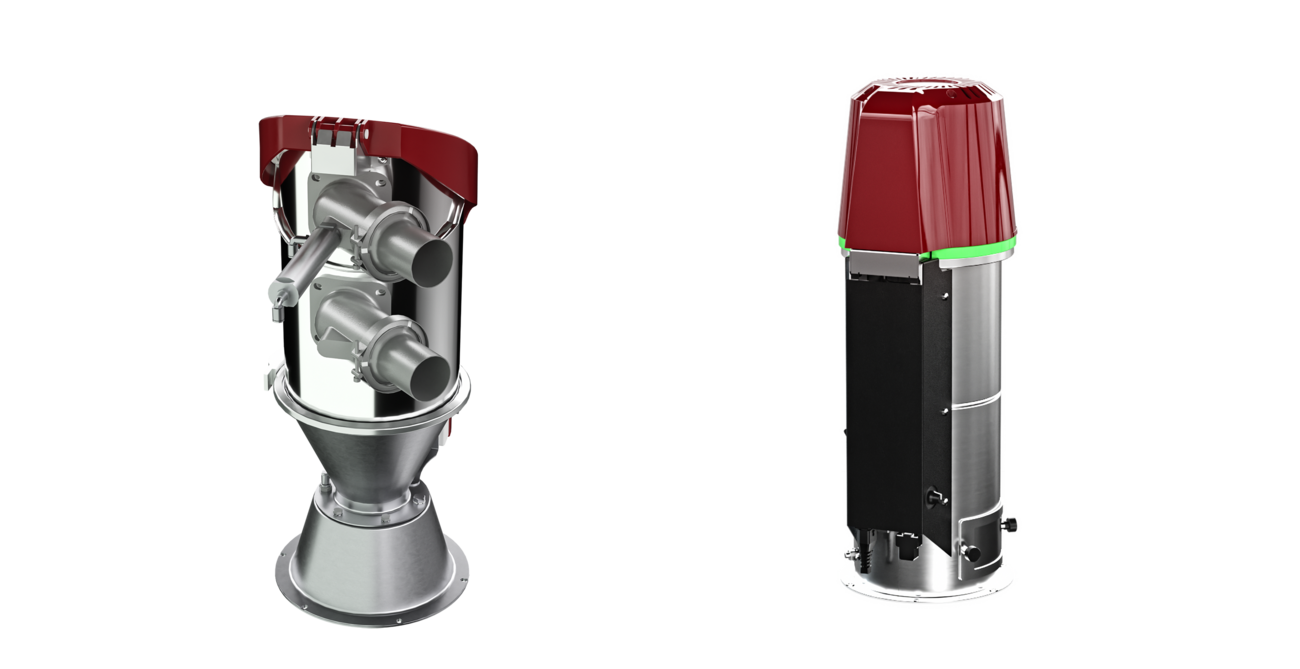

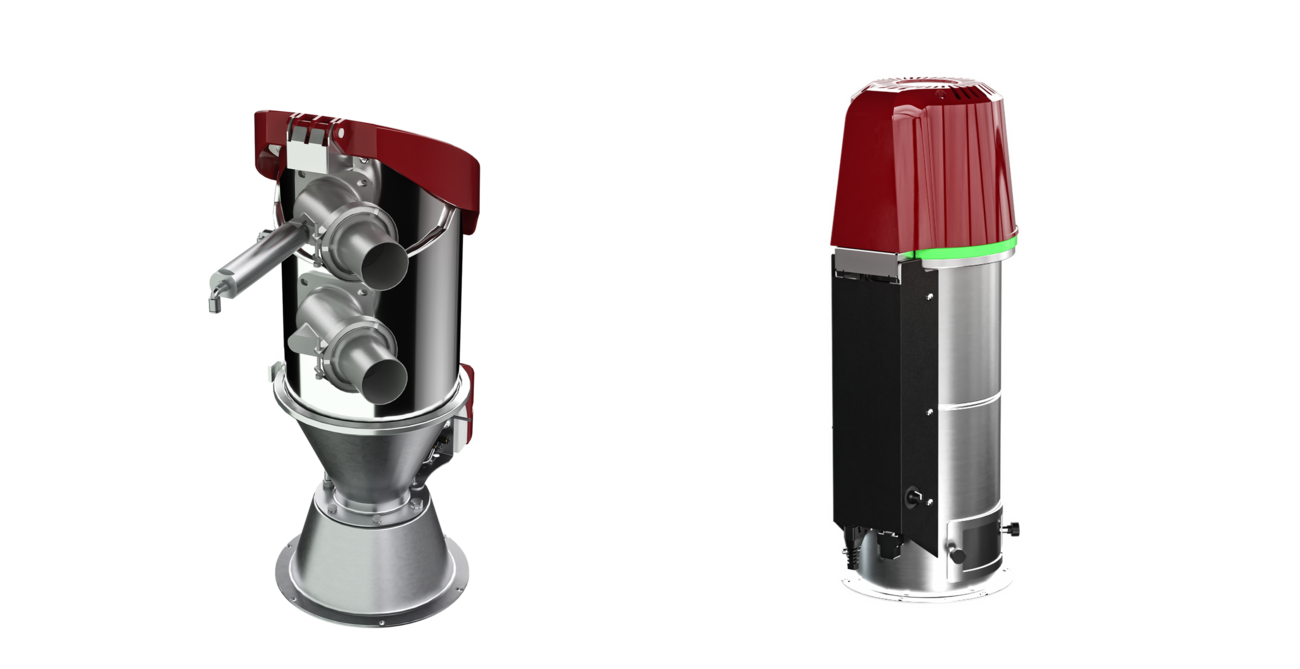

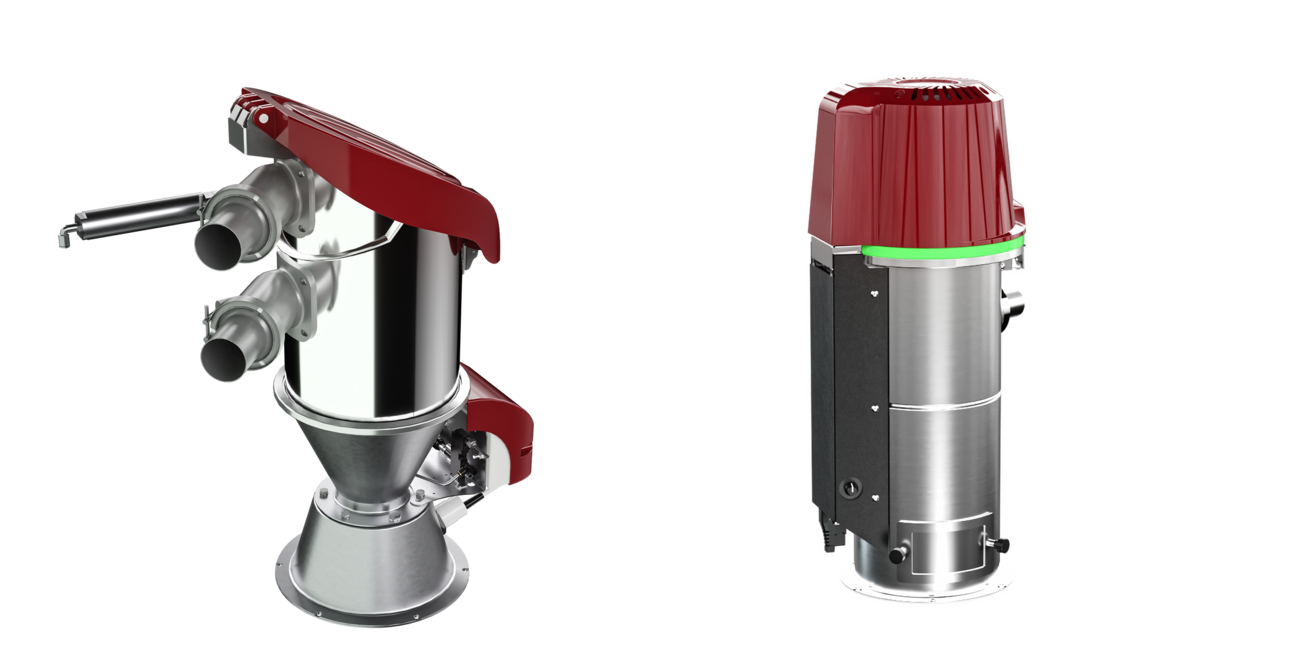

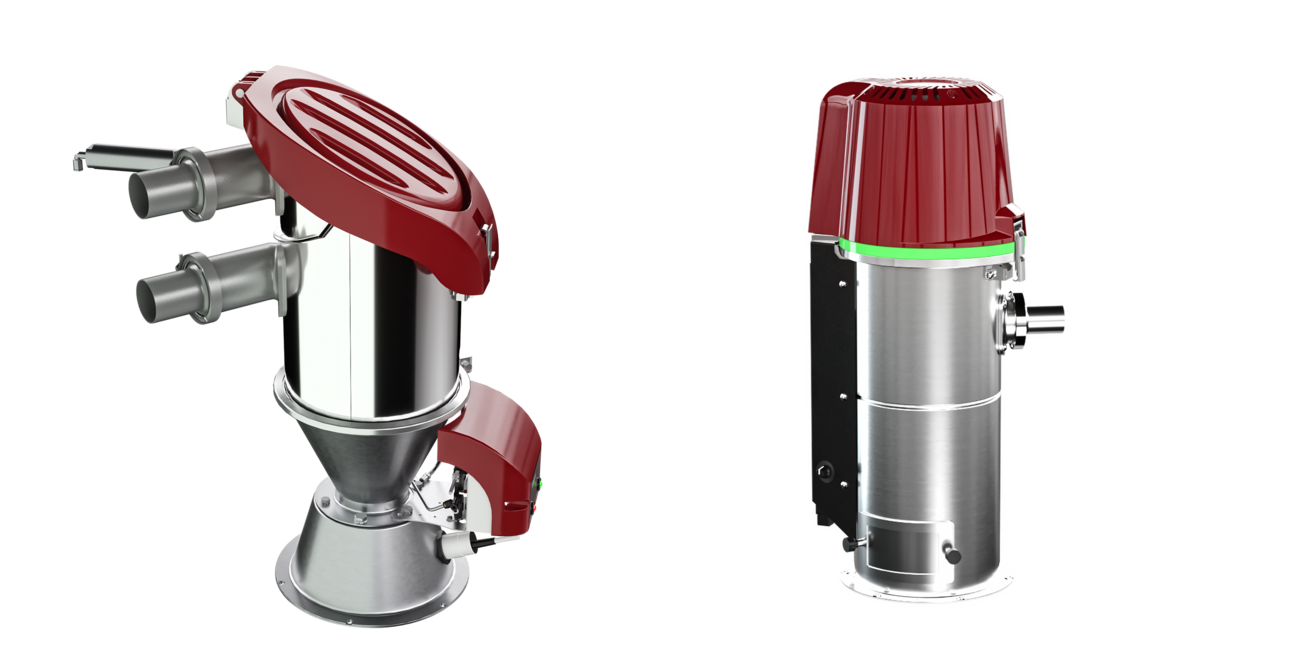

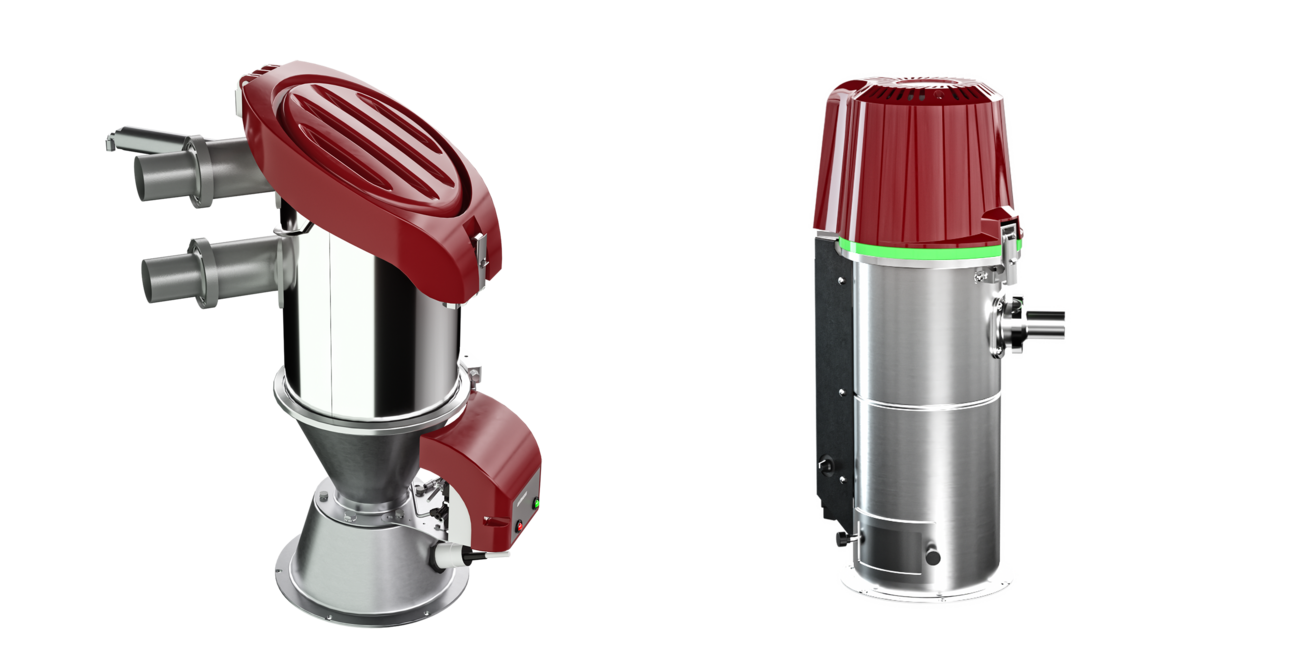

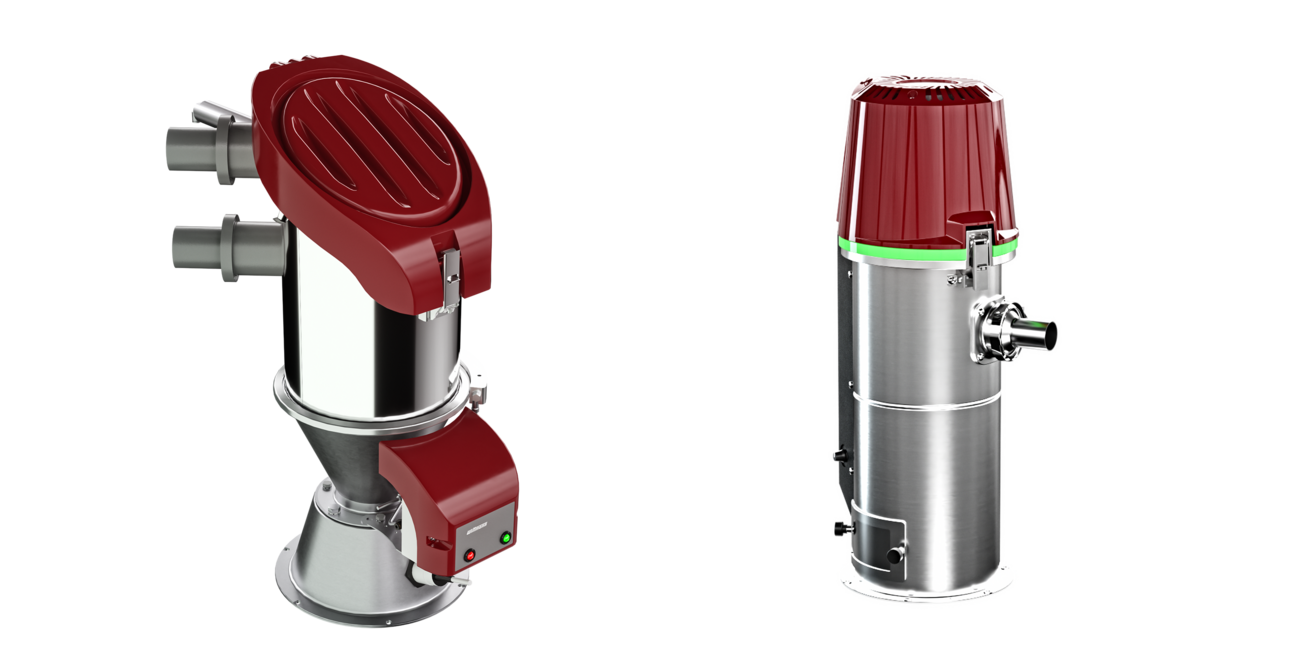

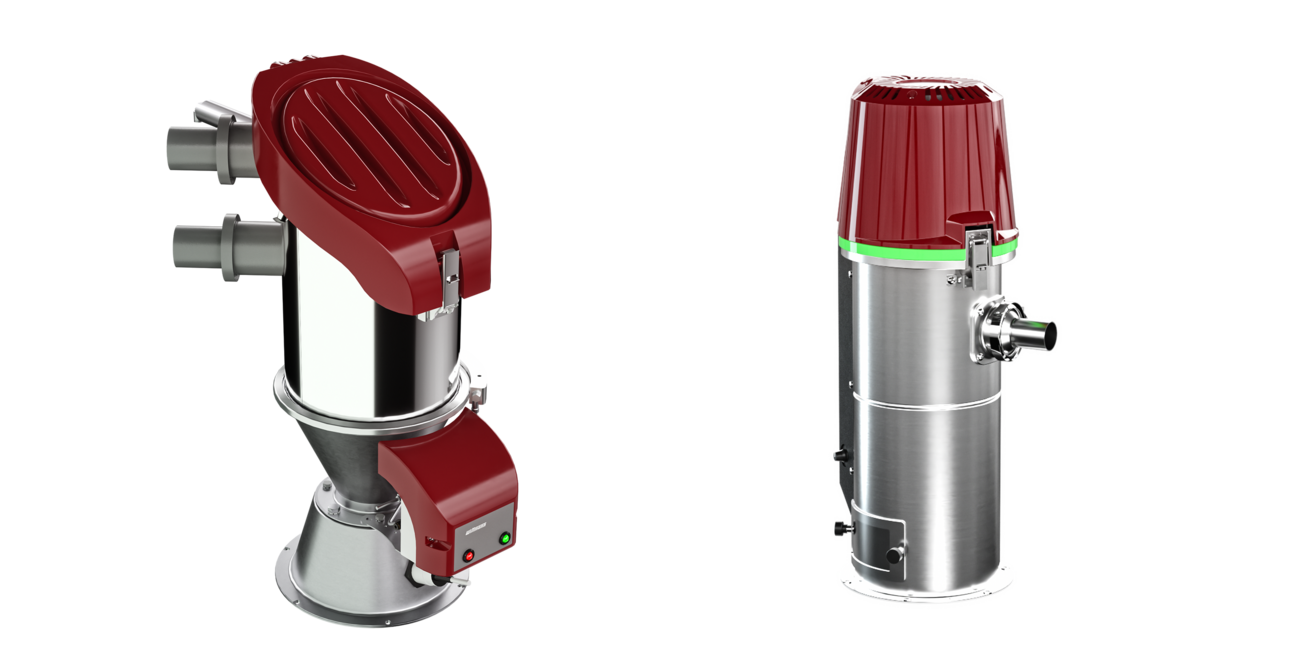

Feedmax S3 net

Single Material Loader

Optimized single loader for flexible conveying of smaller material volumes of up to 176 lbs/h in permanent operation. Peak performance of up to 330 lbs/h.

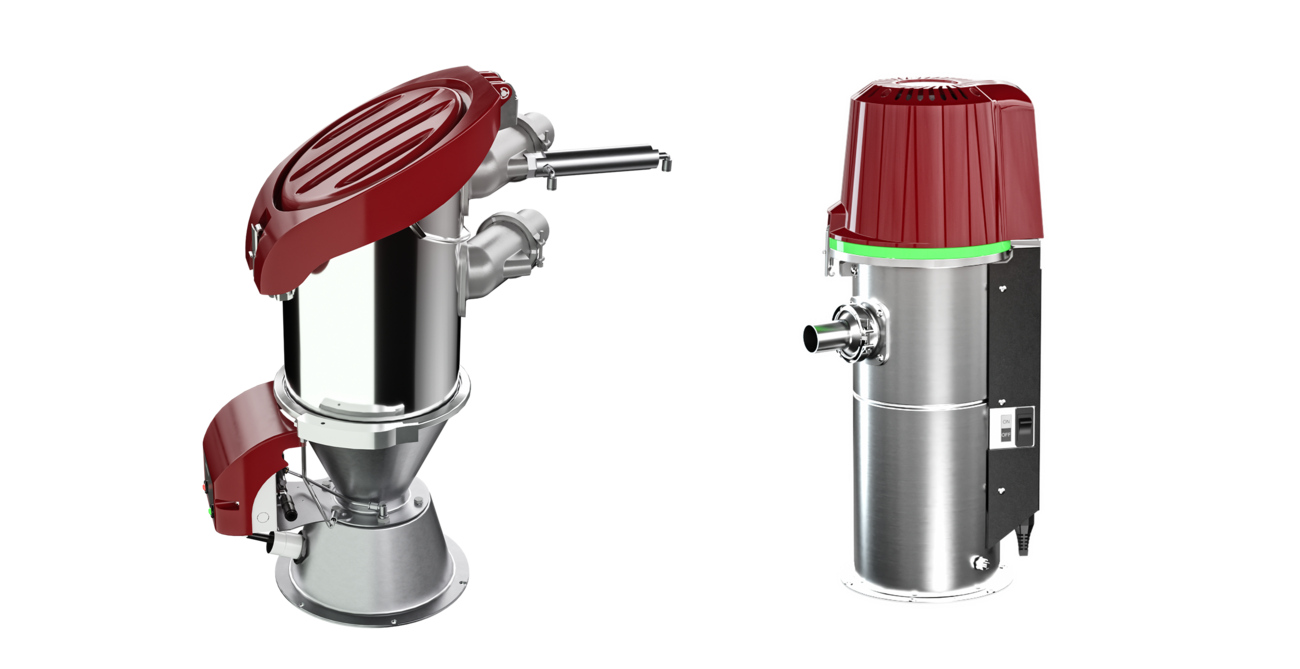

Feedmax S3 net Features

- Robust stainless steel construction – All components in contact with material are made of stainless steel and are therefore perfectly suited for critical and abrasive applications.

- Polyester filter with blow-back cleaning to achieve a longer lifetime a polyester filter was used. The cloth-like filter surface is ensuring that any intake and accumulation of dust particles is made impossible. This filter is never losing its shape, and it is held in position during the entire conveying cycle, ensuring an absolutely unproblematic buildup of vacuum.

- Wand – Included in the standard package is a 780 mm long wand with air vents for the adjustment of the material load, as well as a 5 m PVC hose.

- AmbiLED – Light signal in different colors at the hinged lid for the visualization of internal operating conditions.

- Granulator operating mode – Adjustable timer function for the emptying of a granulator regrind bin.

- Teachbox basic – Optional teach pendant for remote access when the loader is mounted on blenders or tall machine hoppers. Via the touch display, the control of up to 24 material loaders is possible.

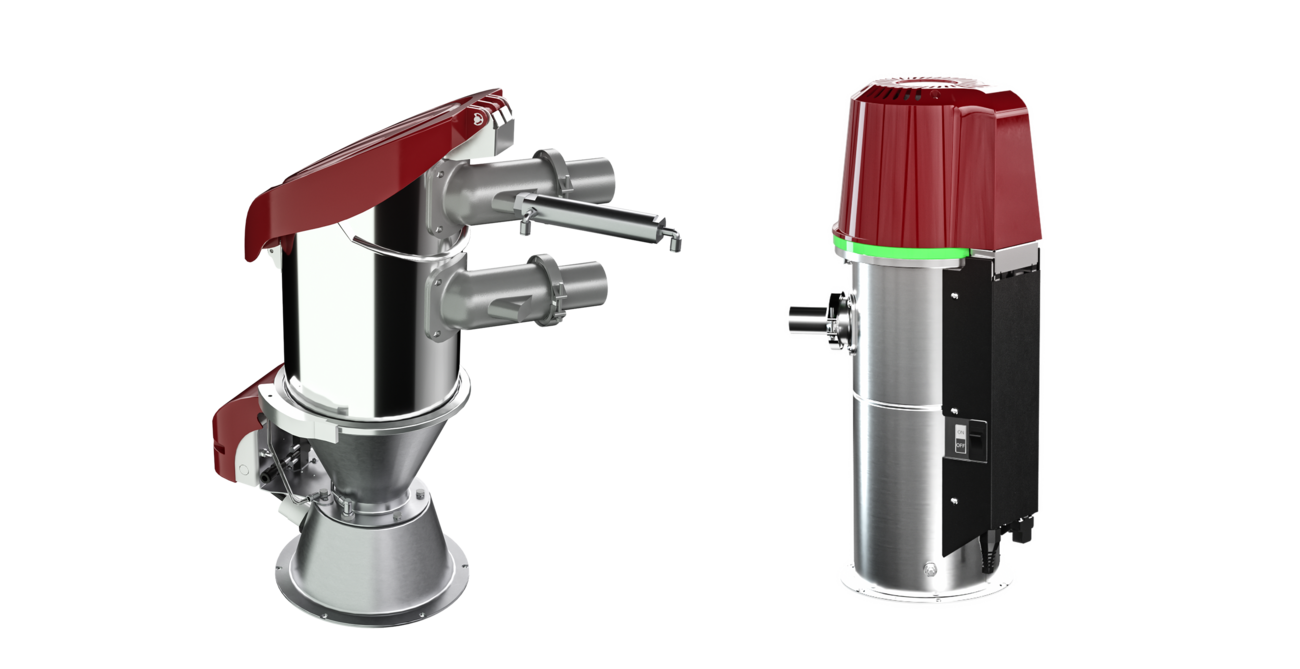

- Proportional valve (optional) for the conveying of two components is externally attached to the material inlet. The dosing relation can be set easily via a Potentiometer.

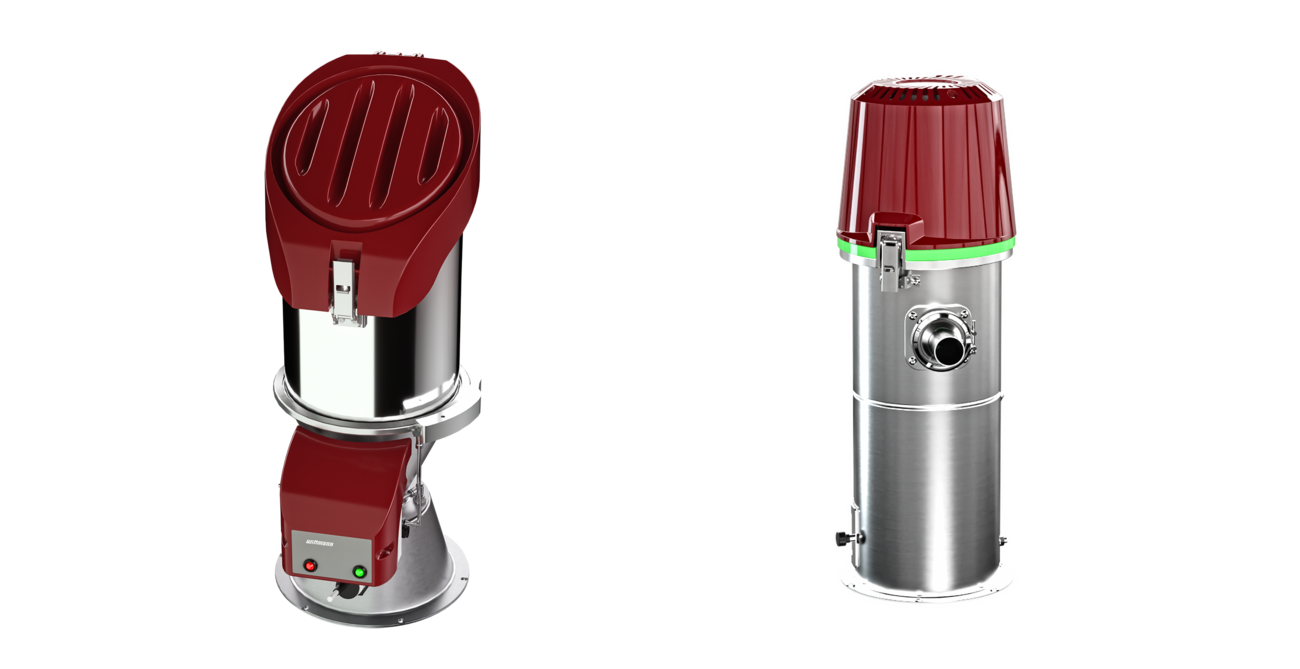

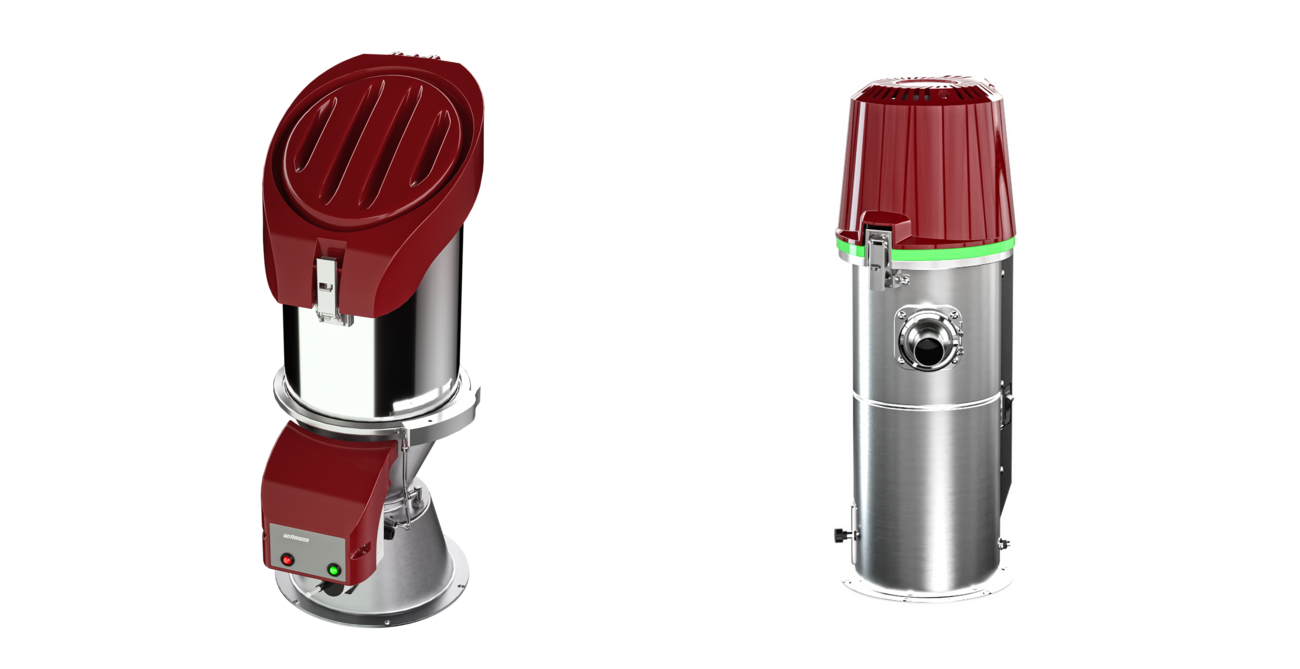

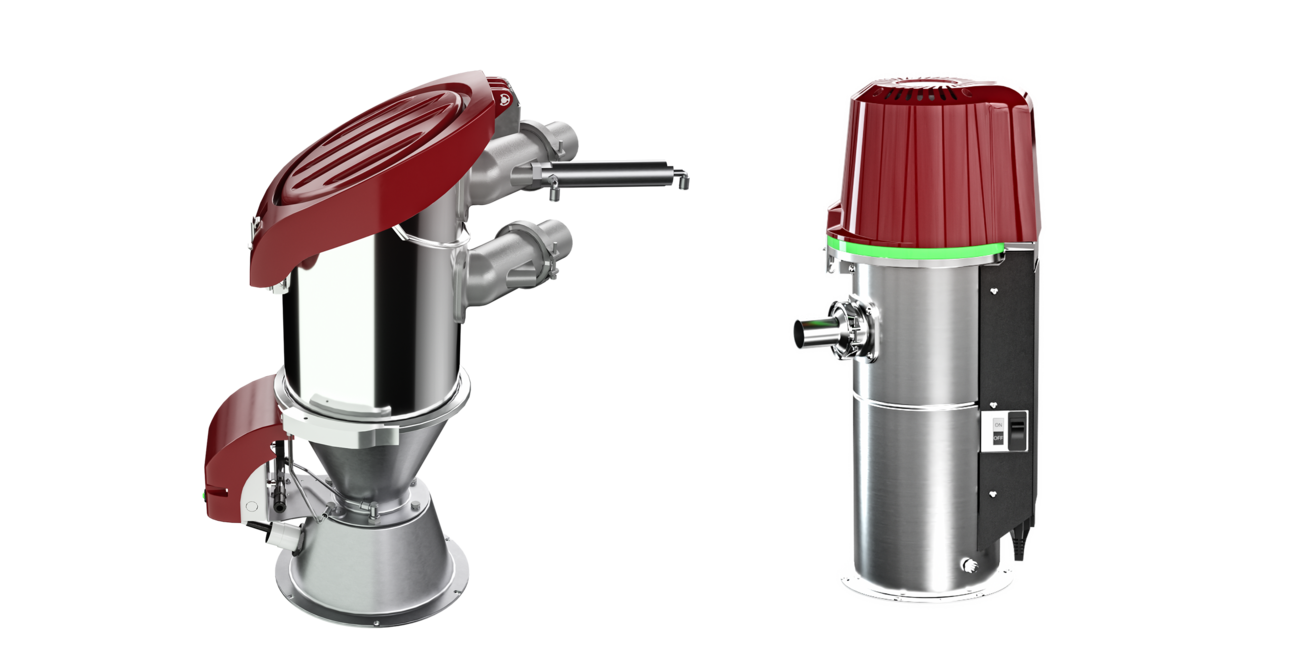

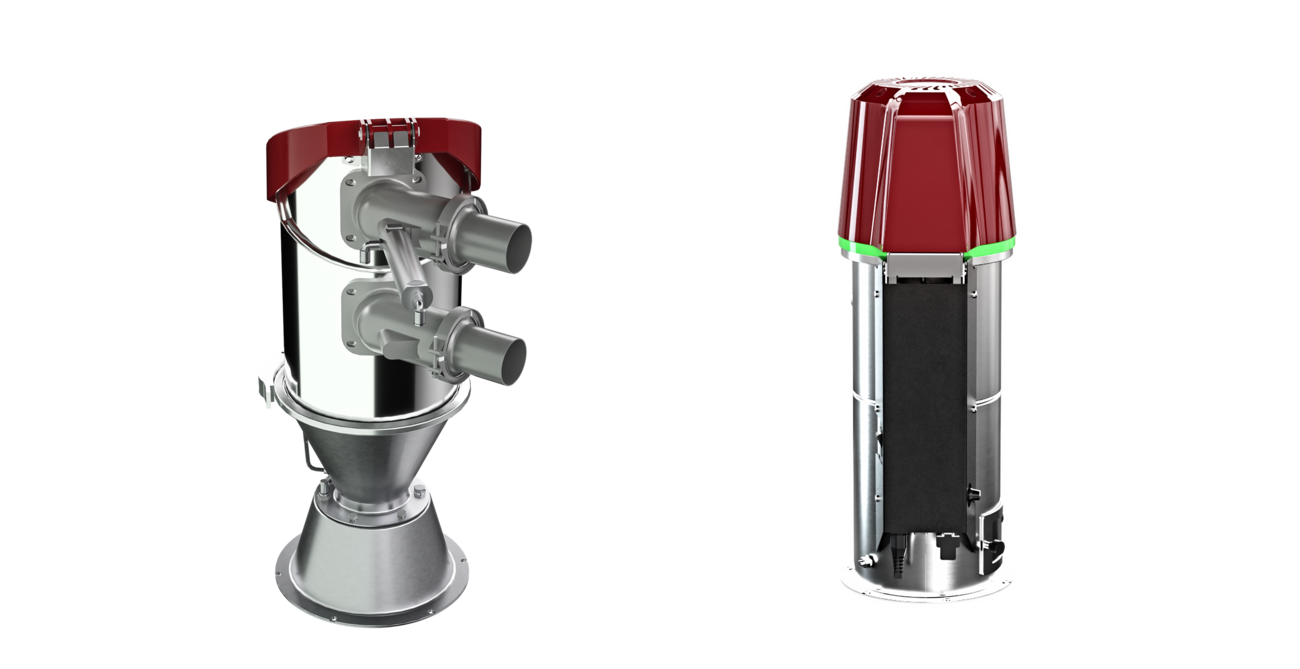

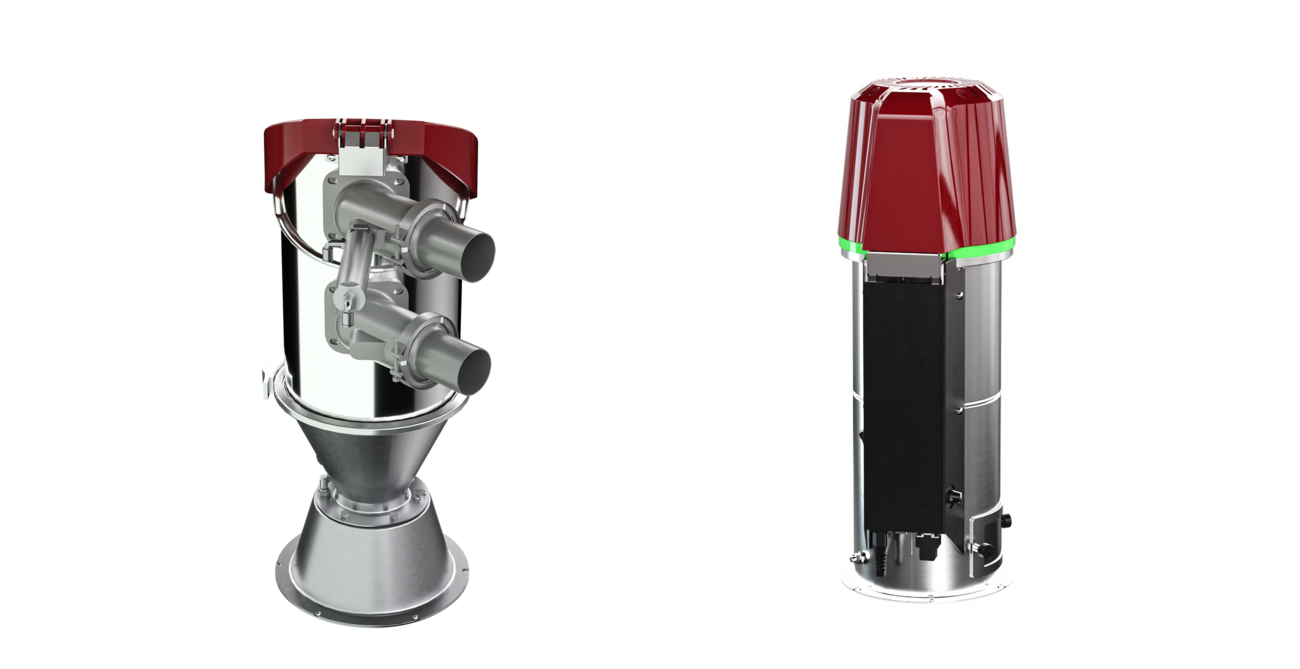

FEEDMAX basic/plus

Central Material Loaders

These units combine the advantages of a single loader with those of central material loaders.

- Material contacting components made of stainless steel

- Vacuum connection with sealing surface

- Hinged lid with integrated screen

- Inlet with proper wall thickness, special steel precision casting

- AmbiLED status Display

Feedmax basic

A practical, newly designed appliance with the appearance of a single loader, and it has to be combined with high-performance blowers, so that it can reach a higher material throughput and handle material conveyance over longer distances.

Feedmax plus

Based on the central loaders with pneumatic discharge shut-off valves, the Feedmax plus offers the possibility of controlling up to 24 devices using the Teachbox basic touch-screen remote control – even in combination with Feedmax basic.

Teachbox basic

Net5 system – Teachbox basic

The graphical surface of the Teachbox basic allows for the control of up to 24 conveying stations, up to two vacuum circuits. Beyond that, the control of filter stations and suction valves is possible. Linked units are identified automatically. These units are displayed on a highres 4.7" touch-screen: for simple operator guidance and process parameter Display.

Clearly Arranged Screen View

Clear graphical display of units, including status display

Versatile Setting Possibilities

Easy change of settings for conveying and vacuum (depending on the preset user rights)

Display and Administration of

– up to 24 Feedmax S3 net

– up to 24 Feedmax basic or Feedmax plus

– up to 2 vacuum lines and 1 back-up blower

Filter Stations and Machine Hoppers

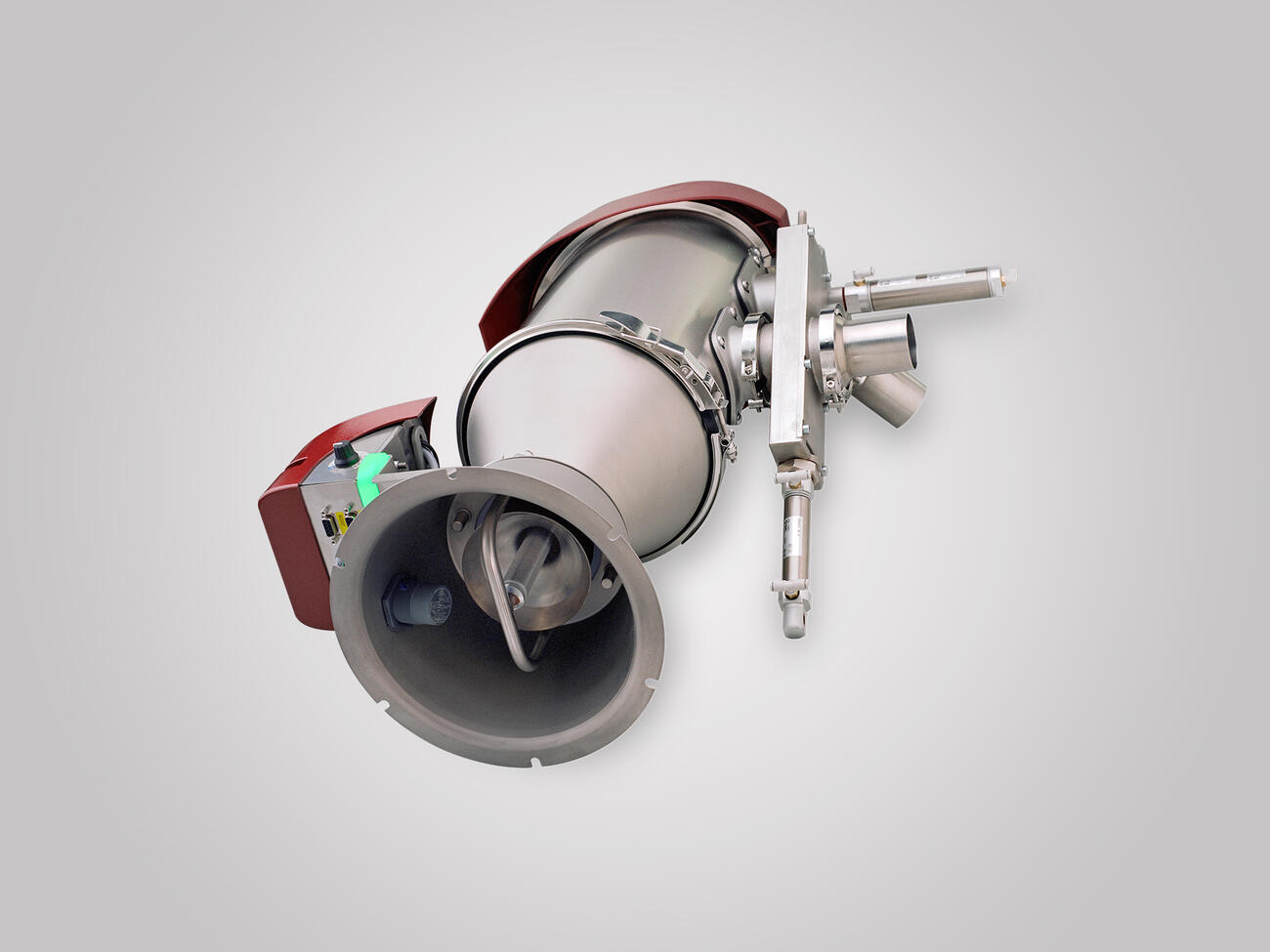

Central Filter Stations for VS

CS Cyclone Filter Station

- 2-stage filtration system – In first stage pre-filtration takes place by means of the cyclone effect and in the second stage, micro filtration occurs by means of a polyester micro filter.

- Effective dust blow-off and user-friendliness – The filter surface is cleaned by means of implosion, and the dust is blown into a dust collection bag. For visual inspection, the dust container is executed in robust glass.

XMB Filter Station

- 2-stage filtration system – In first stage pre-filtration takes place by means of the cyclone effect and in the second stage, micro filtration occurs with a polyester micro-filter having 3 m2 of surface area.

- User-friendly – The dust container can be removed during operation for emptying.

- Choice of dust container – The dust collection area is kept pressureless through a shut-off valve in the discharge cone of the filter and therefore allows the use of any dust collection container, e.g. a plastic bag.

Machine Hoppers for Feedmax

Ranging in size from 3 l to 60 l guarantee the optimum volume of the material inventory to the total material throughput and thus, the performance of the entire System.

Downloads