LIM – Liquid Injection Molding

LIM – Liquid Injection Molding

Material with great potential for many applications

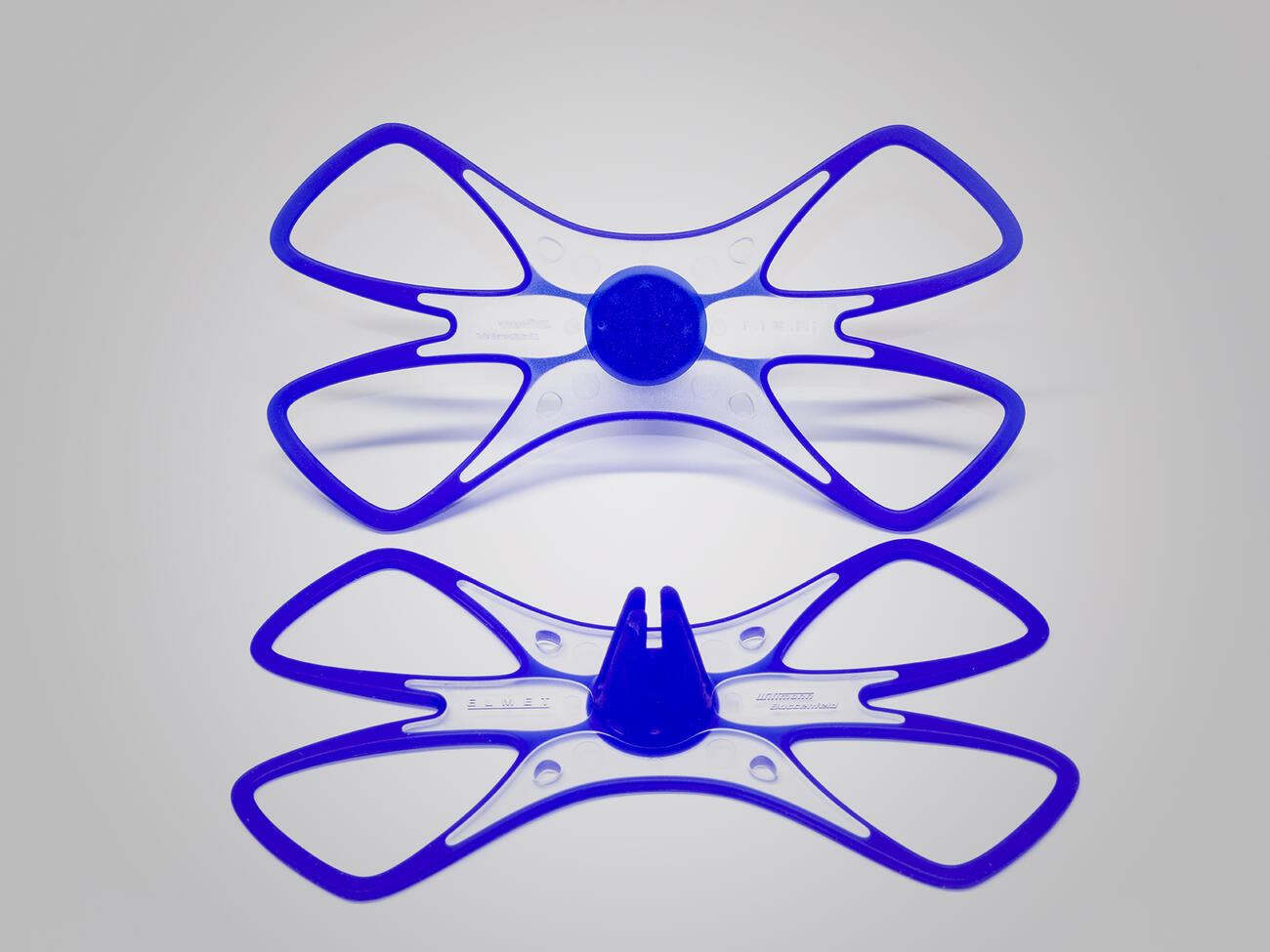

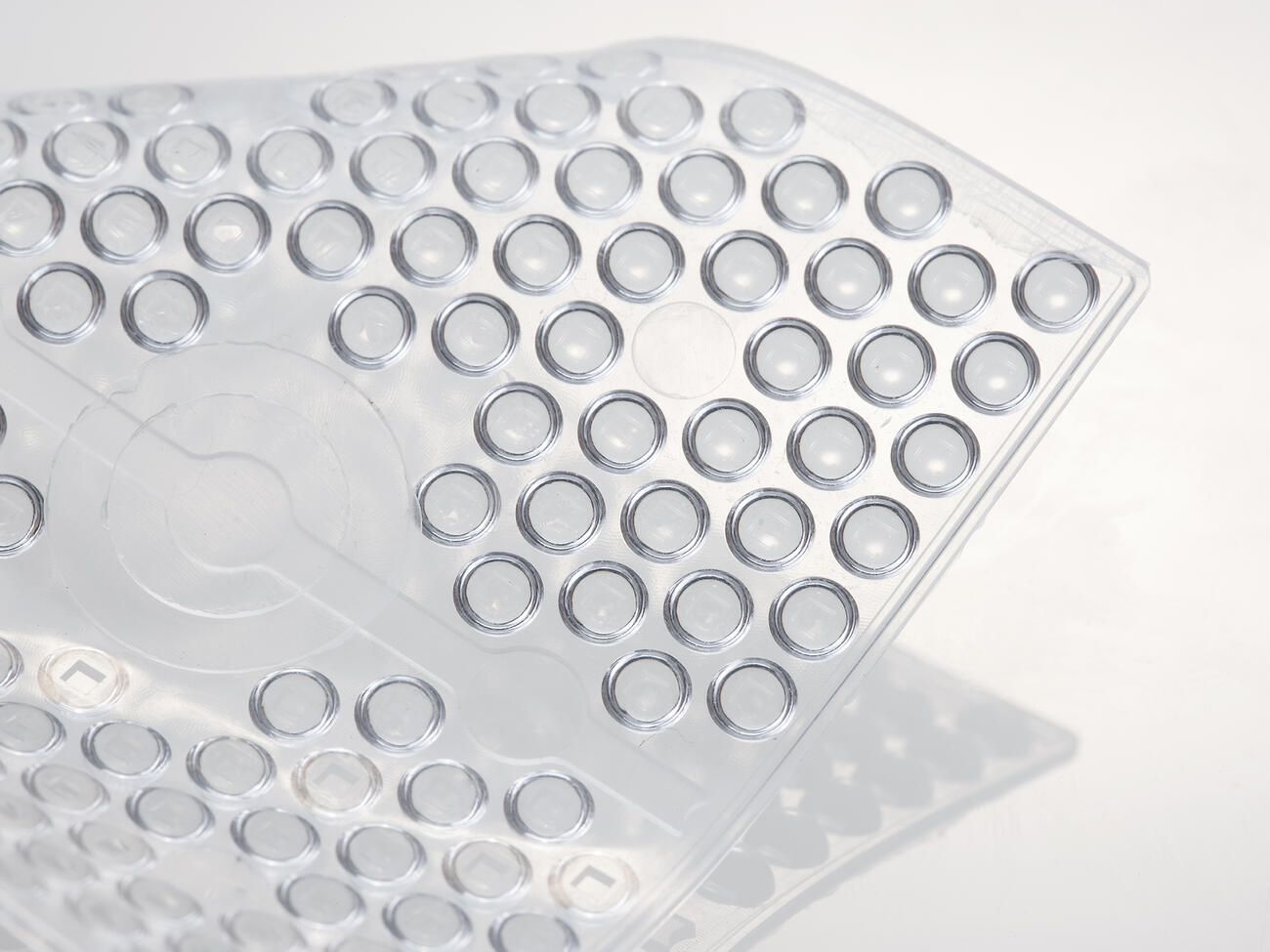

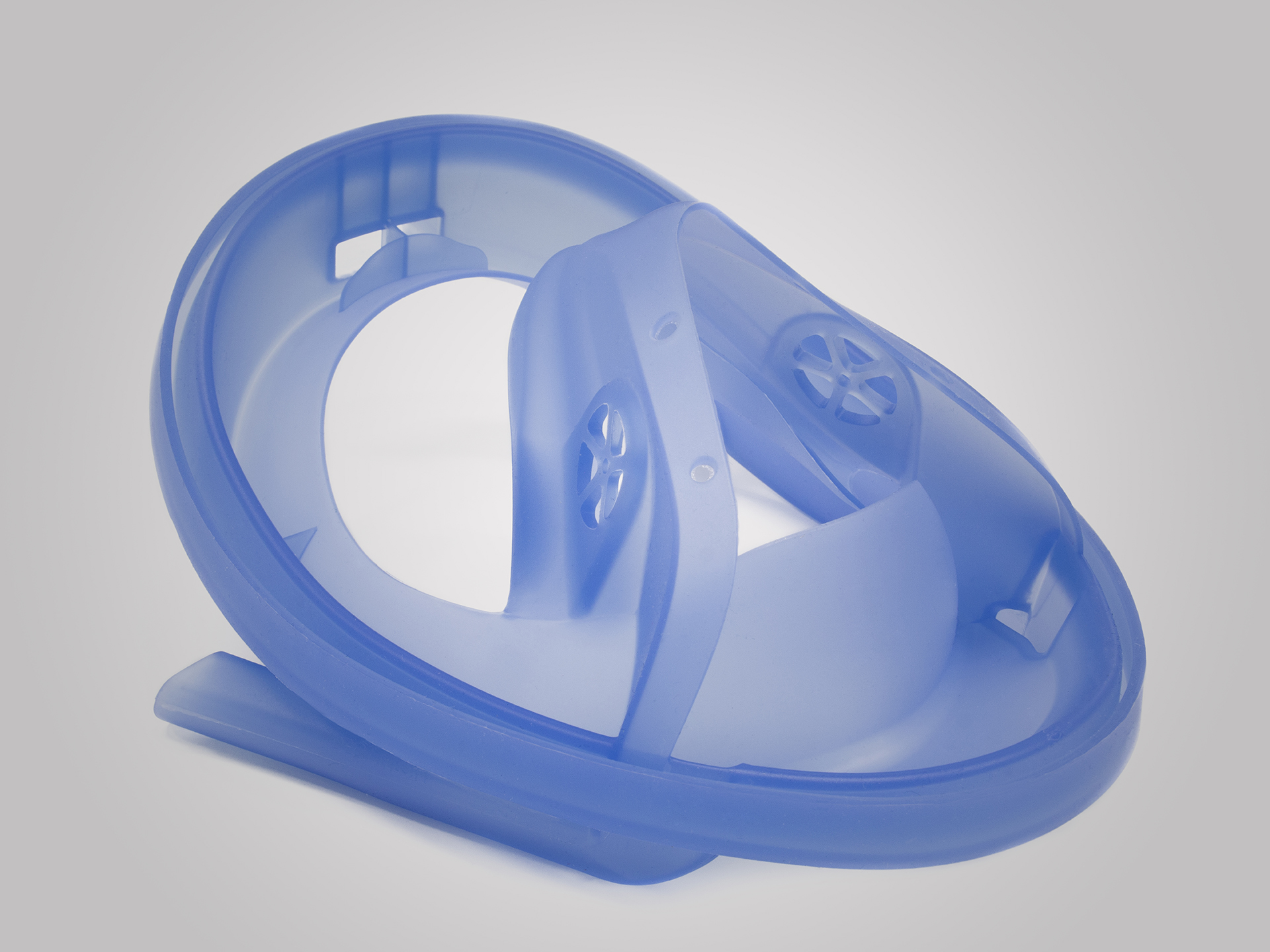

LIM application

LIM is the injection molding process used to manufacture elastic parts made of two component liquid silicon rubber (LSR – Liquid Silicon Rubber).

Advantages of the LIM application

- Extensive range of applications from – 50 to + 250 °C

- High flashpoint and advantageous fire behavior

- Good electrical insulation property

- Excellent resistance to weathering and aging

- High dimensional stability even under long-term load (sealing)

- High bio-compatibility, odor and taste neutrality (medical use, baby care, etc.)

LIM equipment

The basic machines for LIM injection molding are the standard machines from the MicroPower, SmartPower and EcoPower series. Injection units specially adapted to the material attributes of liquid silicone and other LSR-specific equipment options characterize the LIM machines from WITTMANN BATTENFELD. The LIM equipment package follows a modular concept like the standard machines. It covers a wide range of injection volumes and mold sizes.

The LIM equipment options:

- Injection unit with pneumatic shut-off nozzle for 2-component liquid silicone processing

- Spring-activated check valve

- Interface for 2-component mixing and metering system

- Cooling circuit drillings in the mold platens

- Vacuum package

- Cooling water monitoring

- Flushable water filter

Moreover, an extensive range of equipment package options is available to adapt the machine individually to the relevant application.

Advantages of the equipment

- Easy access to the injection unit for cleaning and maintenance.

- A spring-activated disk check valve version, which allows active closing and prevents the low-viscosity material from flowing back during injection

- Parameter setting and regulation as well as monitoring (also of auxiliary equipment) directly via the machine control unit

- High quality standard

- Clean production, less waste

- Repeatable quality and economic production of large quantities

Downloads

References