EcoPower B8X 55 – 300 t

EcoPower B8X 55 – 300 t

Energy saving, clean, compact

The new benchmark for electric machines

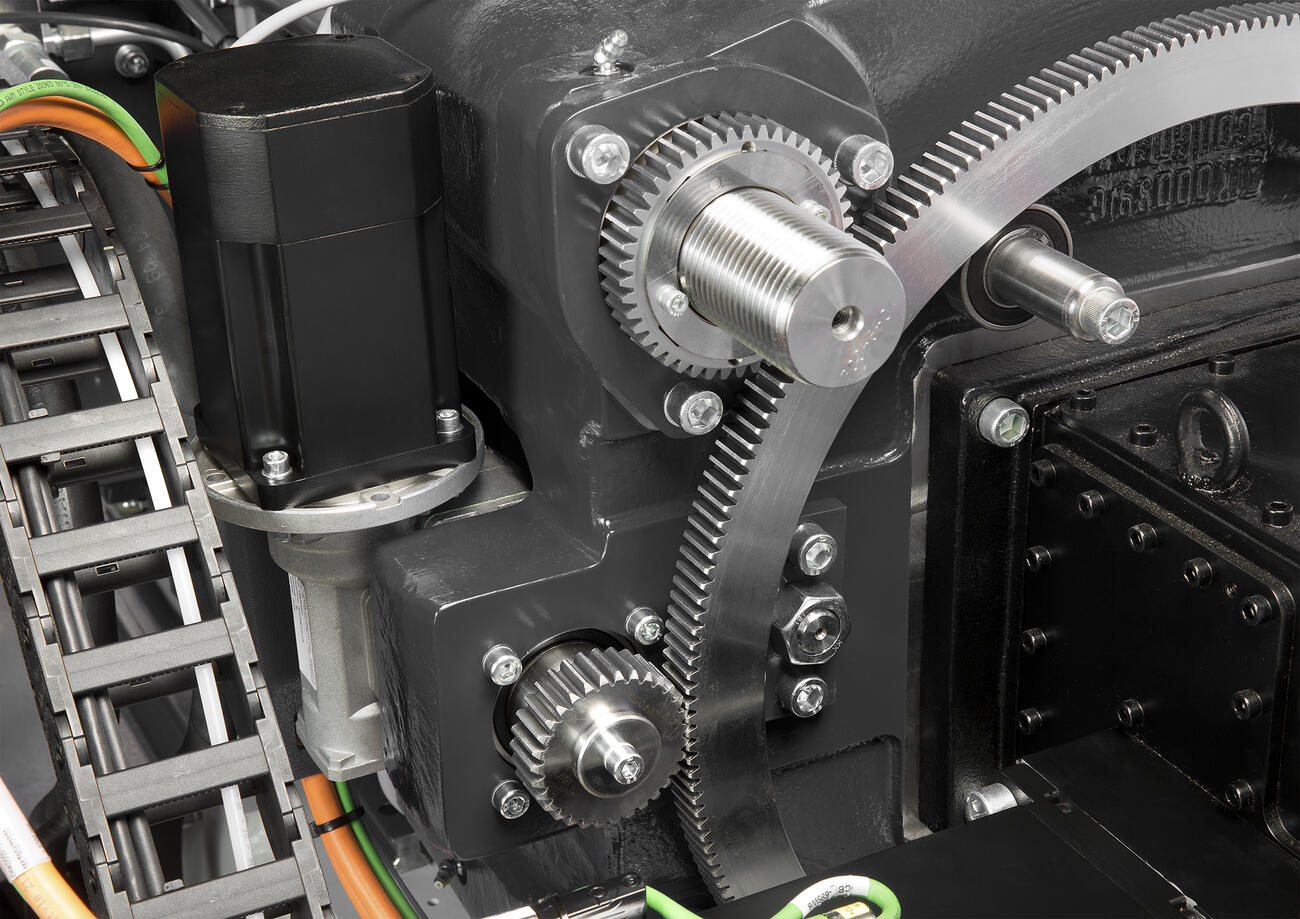

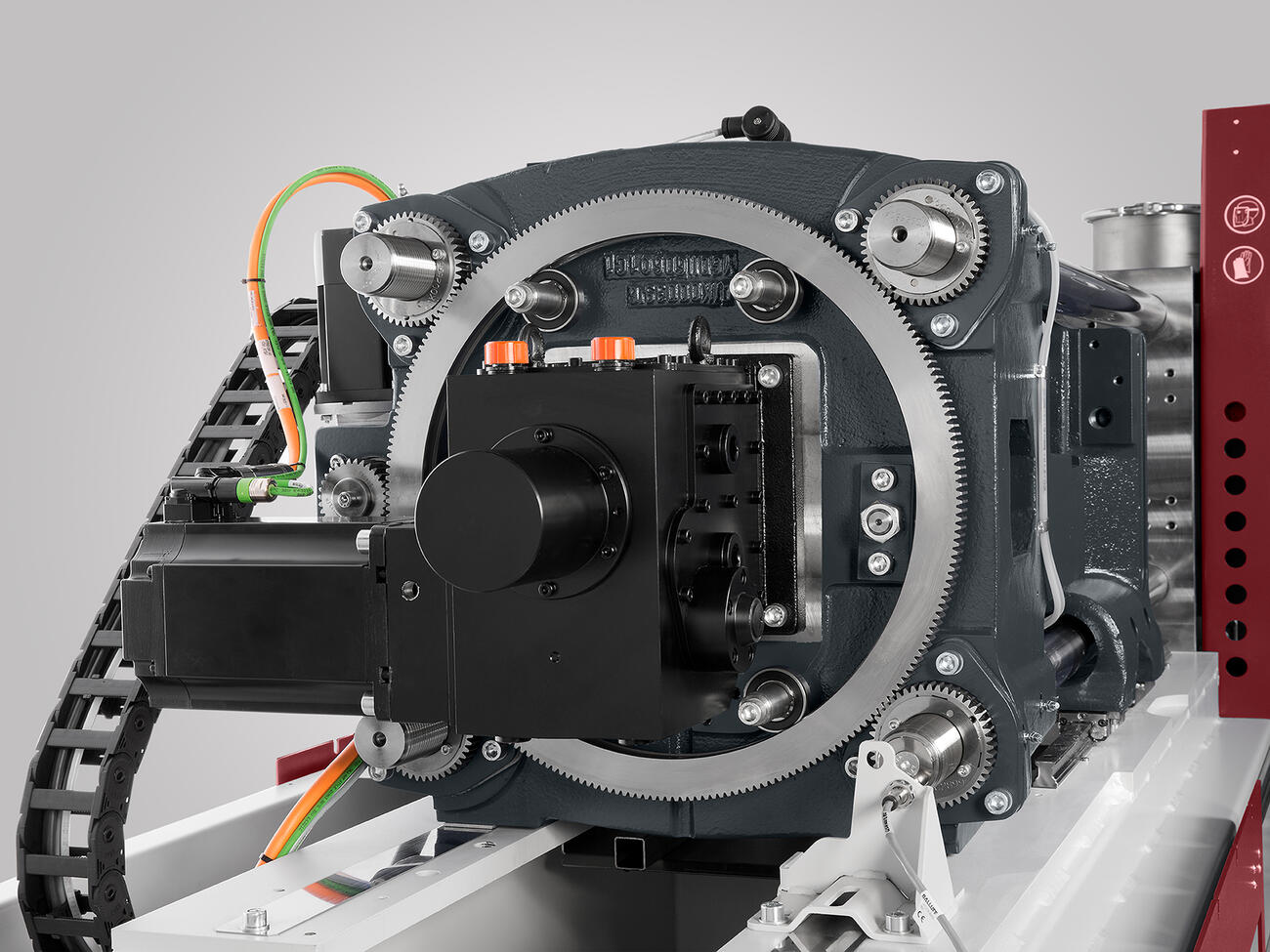

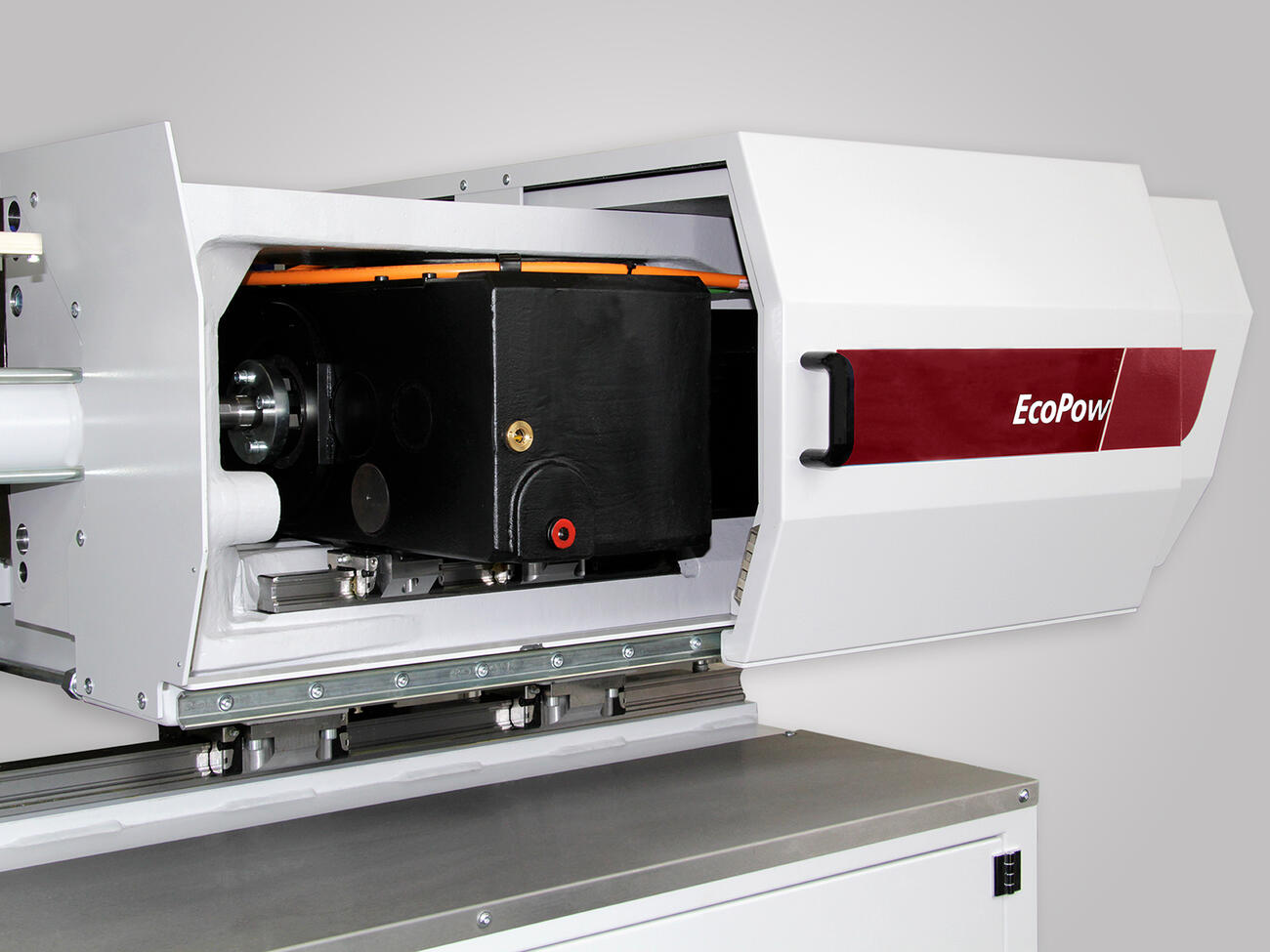

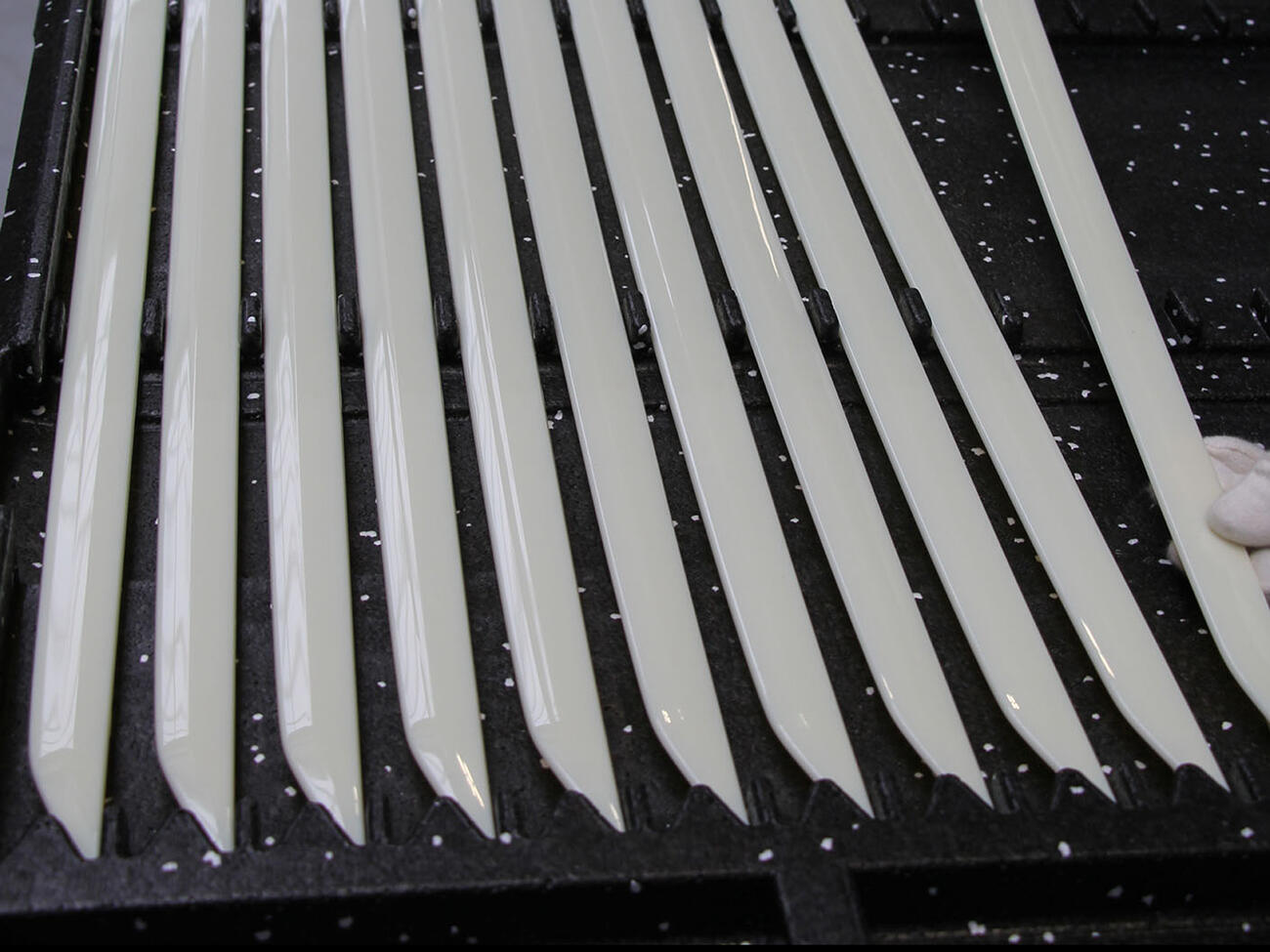

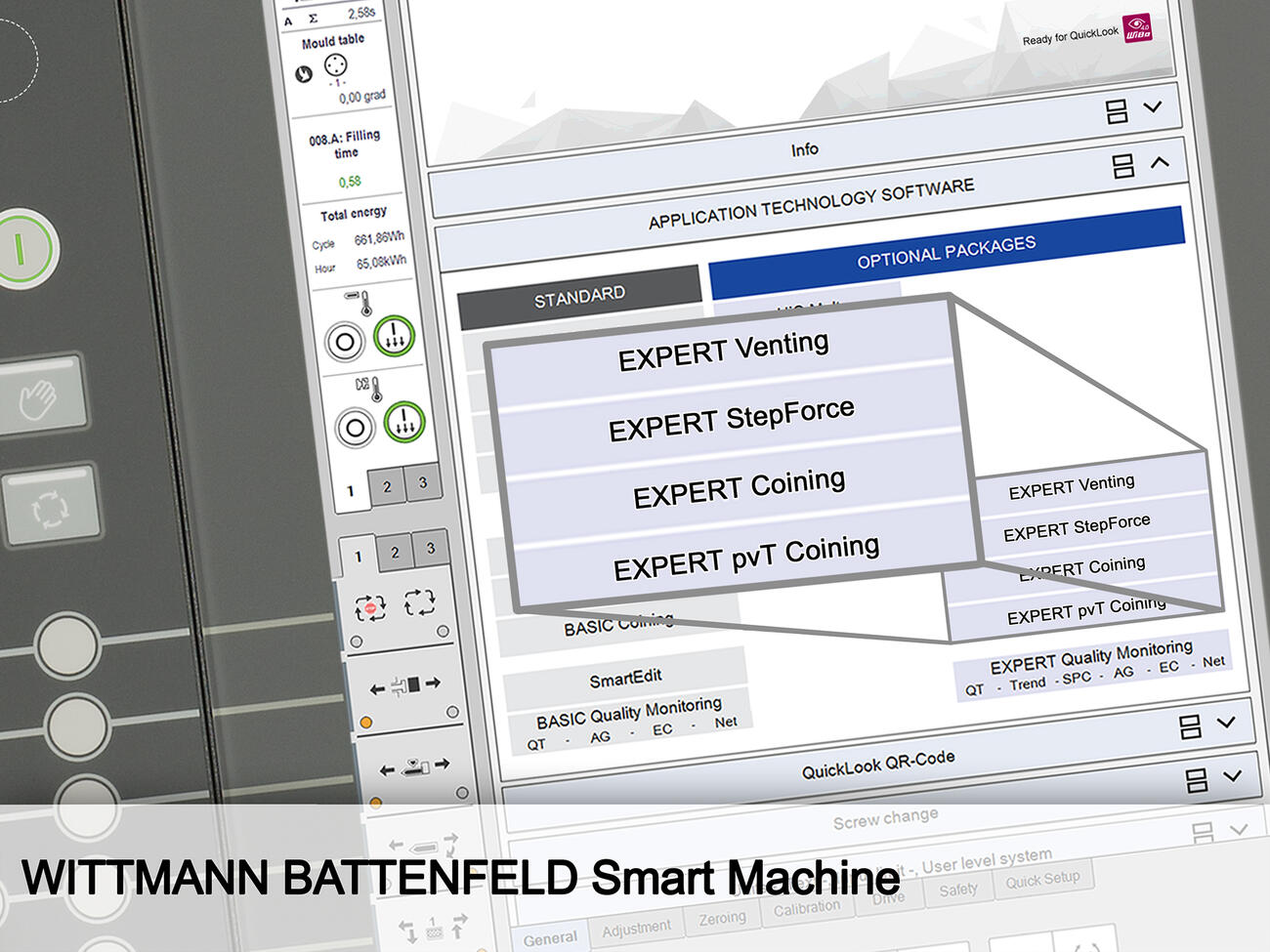

The beltless EcoPower scores with a compact injection unit and the clean design of its clamping unit, featuring a highly efficient direct drive. The braking energy of the drives, normally returned to the power supply network by an elaborate process, is completely utilized by the EcoPower within the machine to provide the necessary voltage for the control system and for barrel heating. Thus, these machines are extremely energy-efficient and are a benchmark with regard to their low energy consumption.

Another advantage of the EcoPower is its user-friendly design. In developing this machine series, special emphasis was placed on the small footprint and compact integration.

Advantages

- Fast, precise injection and repeatable holding and back pressure

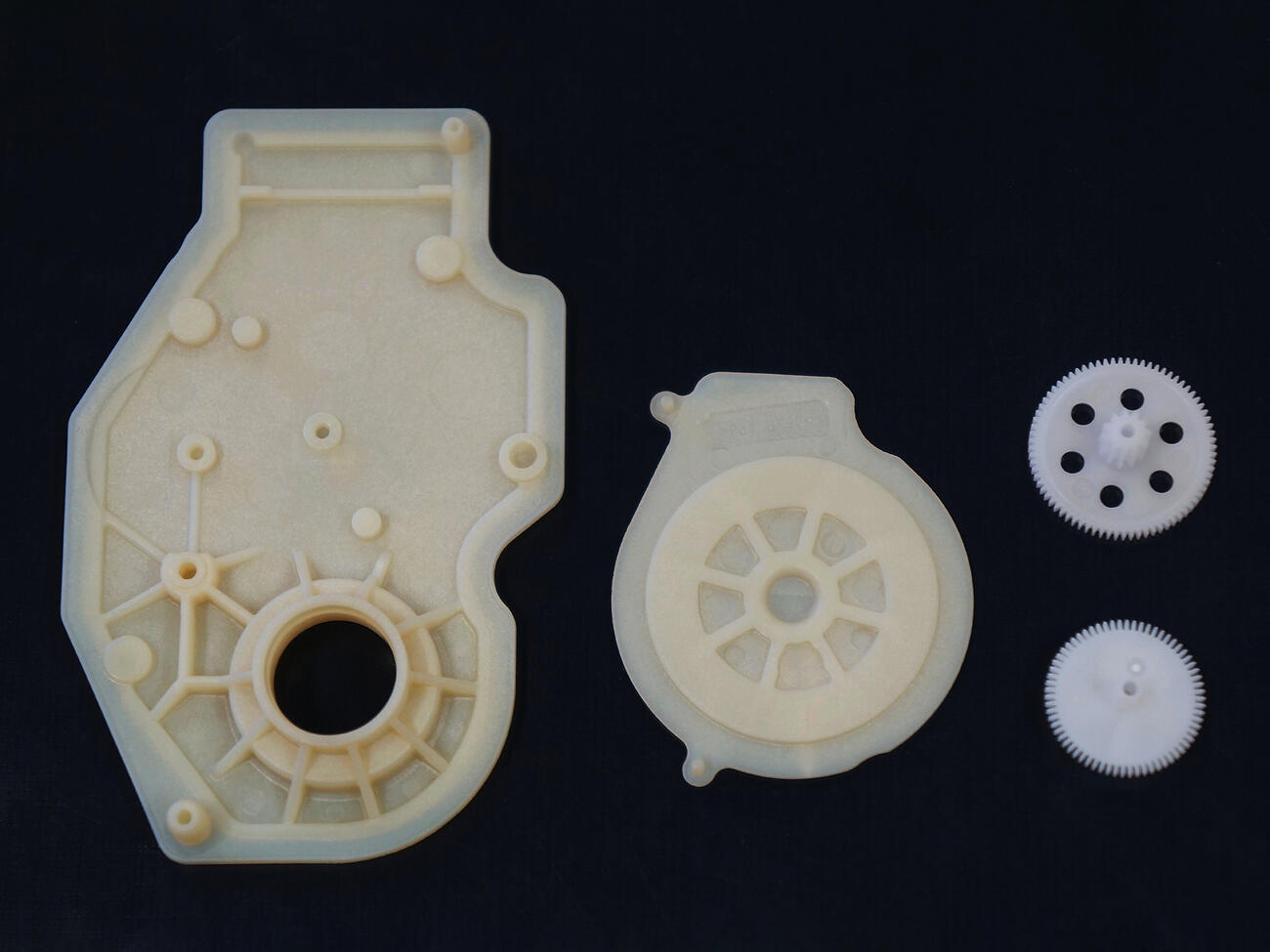

- Clean and compact design of capsuled gear unit

- Minimal energy consumption with internal utilization of braking energy for power supply to the control system and barrel heating

- Modest space requirements and extremely low noise emission

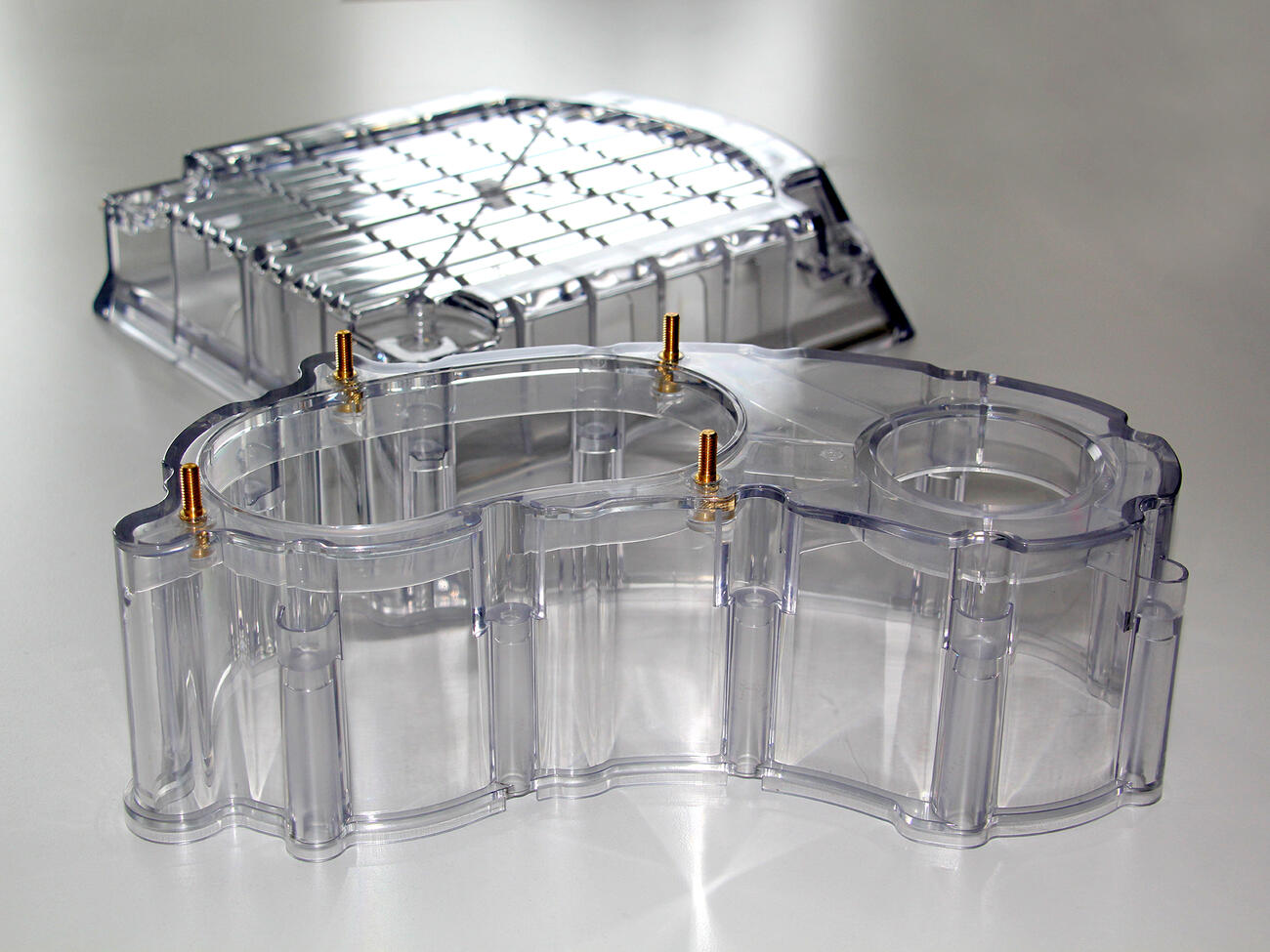

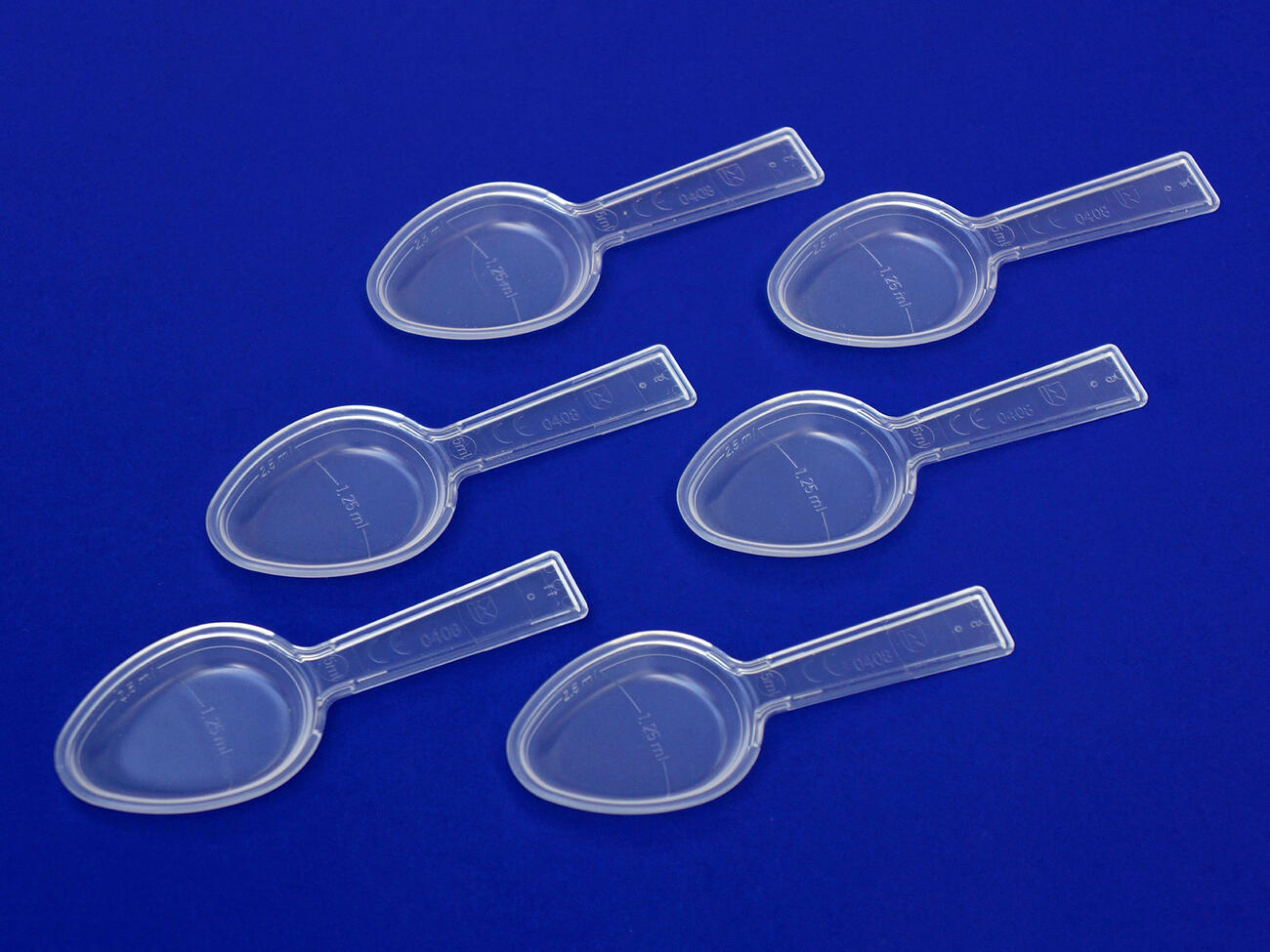

- Modular construction kit for standard, high-performance and cleanroom design

Downloads

References