Kärcher Romania relies on technology from WITTMANN BATTENFELD

Kärcher Romania relies on technology from WITTMANN BATTENFELD

Machines | Automation | Auxiliaries

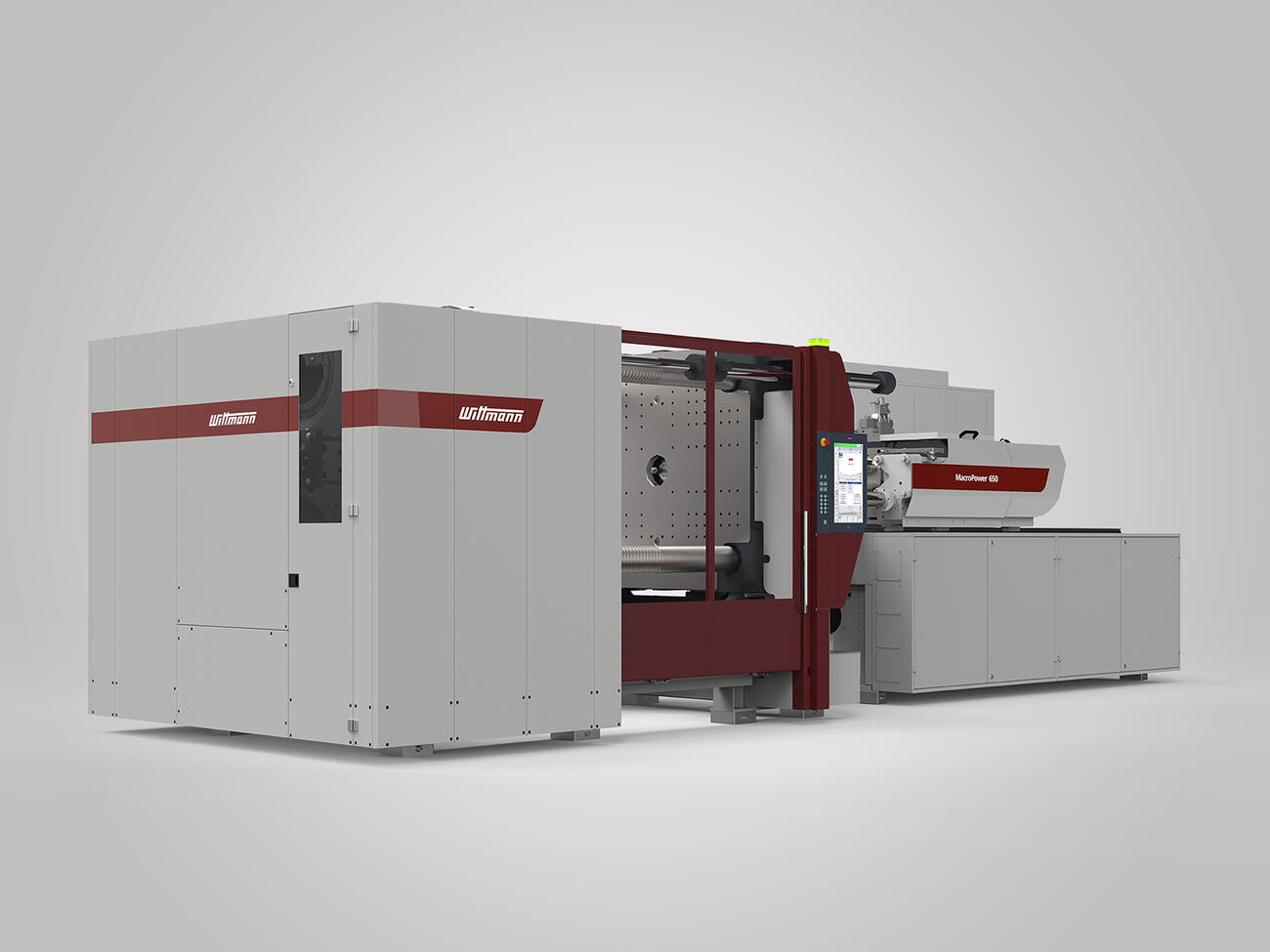

CER Cleaning Equipment in Romania, a company of the German Kärcher Group, has been using machines, automation and auxiliaries from the WITTMANN Group for years. In late 2020 and early 2021, another 18 machines of the MacroPower series were installed at CER Cleaning Equipment.

Kärcher is the world's leading provider of efficient and resource-saving cleaning systems. The company's cleaning devices are characterized by functionality, ease of use and a sophisticated look. More than 1,300 patents and utility models testify to the innovative strength of the Kärcher company. The cleaning equipment is used in both commercial and private areas. The wide range of products from Kärcher includes high-pressure cleaners, scrubbing and suction machines, sweepers, window and surface vacuum cleaners, steam cleaners, air cleaners, generators and dirty water pumps, washing systems, irrigation systems, garden tools and much more.

In the year 2016, Kärcher has started their own production of professional and home & garden vacuum cleaners in Romania with CER Cleaning Equipment based in Curtea de Arges. CER Cleaning Equipment is a 100% subsidiary of the German Kärcher Group.

Since this beginning, the WITTMANN Group has been supplying CER Cleaning Equipment with machines from the EcoPower and MacroPower series, robots and auxiliary equipment. The first 16 MacroPower machines in the clamping force range of 4,000 kN up to 11,000 kN were delivered in 2016. Due to the continuing growth of CER and the high demand for vacuum cleaners, the delivery of a second batch of machines took place in 2018. As growth continued without interruption, another factory building next to the original building had to be constructed starting middle of 2020 with more machines, robots and a central material handling system following as well. At the end of 2020 and the beginning of 2021, WITTMANN BATTENFELD installed another batch of 18 machines from the MacroPower series in the clamping force range from 4,500 to 9,000 kN in the new facility of CER. The machine park of CER Cleaning Equipment currently comprises 44 machines of the MacroPower series and one EcoPower machine.

“The communication with the team from WITTMANN BATTENFELD Romania is excellent. The service we received after delivery of the equipment was very professional.'

Ion Bican, Managing Director of CER Cleaning Equipment

Ke stažení