Presenting at this years COMPAMED

Presenting at this years COMPAMED

Liquid silicone injection molding of micro parts

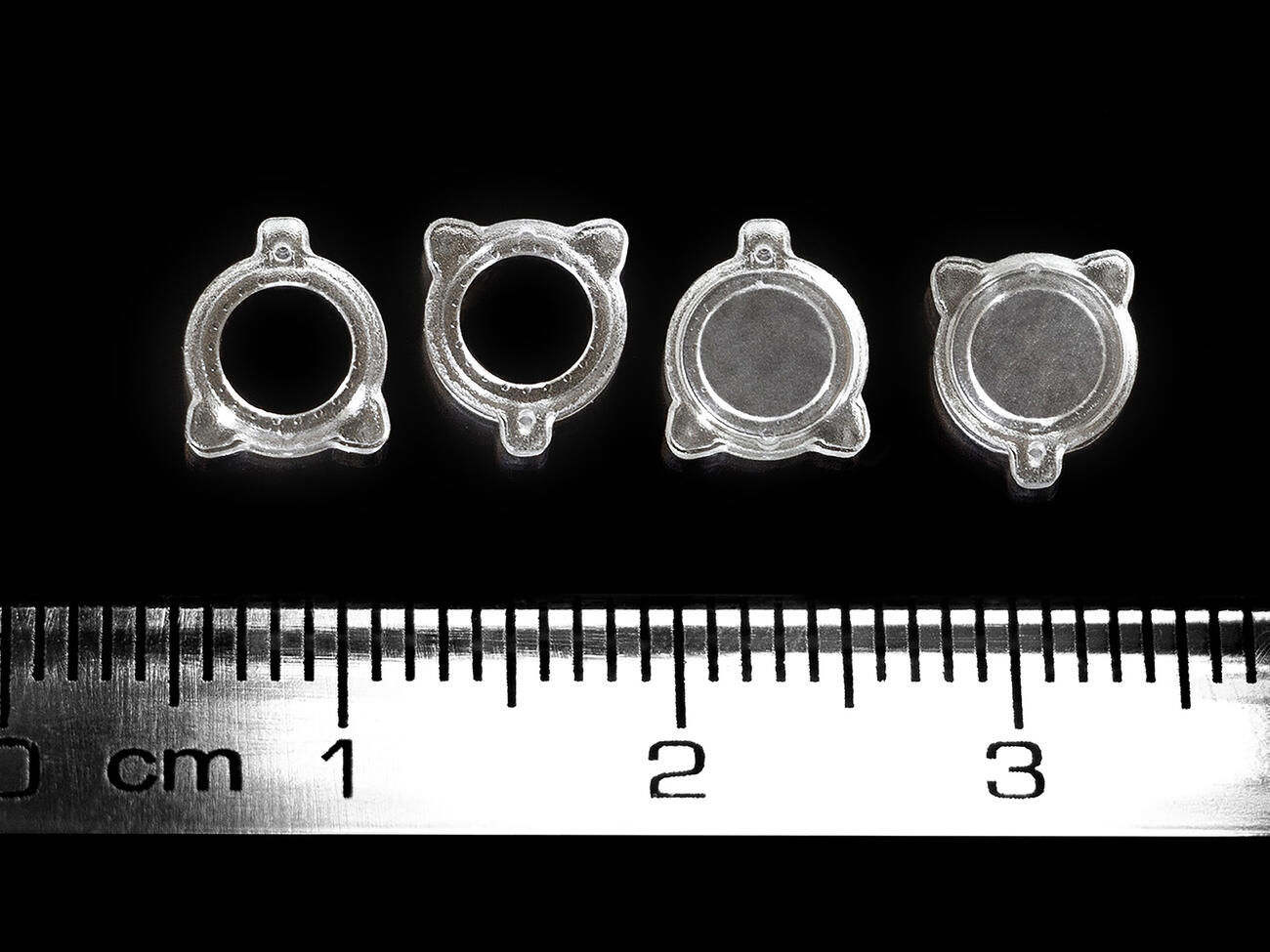

At the Compamed, the international trade fair for the medical manufacturing supplier market and product development held in Düsseldorf from 15 to 18 November 2021, WITTMANN BATTENFELD will produce a micro support ring with a silicone membrane in hall 14, booth A 20 to demonstrate its expertise in the field of liquid silicone processing.

Laying out injection molding machines for liquid silicone processing has a long tradition at WITTMANN BATTENFELD. This type of technology has been used for many years not only on conventional machines, but also on the MicroPower, a machine specially designed for micro parts injection molding.

On this machine, thermally homogeneous melt is injected via a two-step screw-and-plunger injection unit, with shot volumes ranging from just a few mm³ to 4 cm³. In this way, it has become possible to make top-quality parts in an absolutely stable production process and with short cycle times.

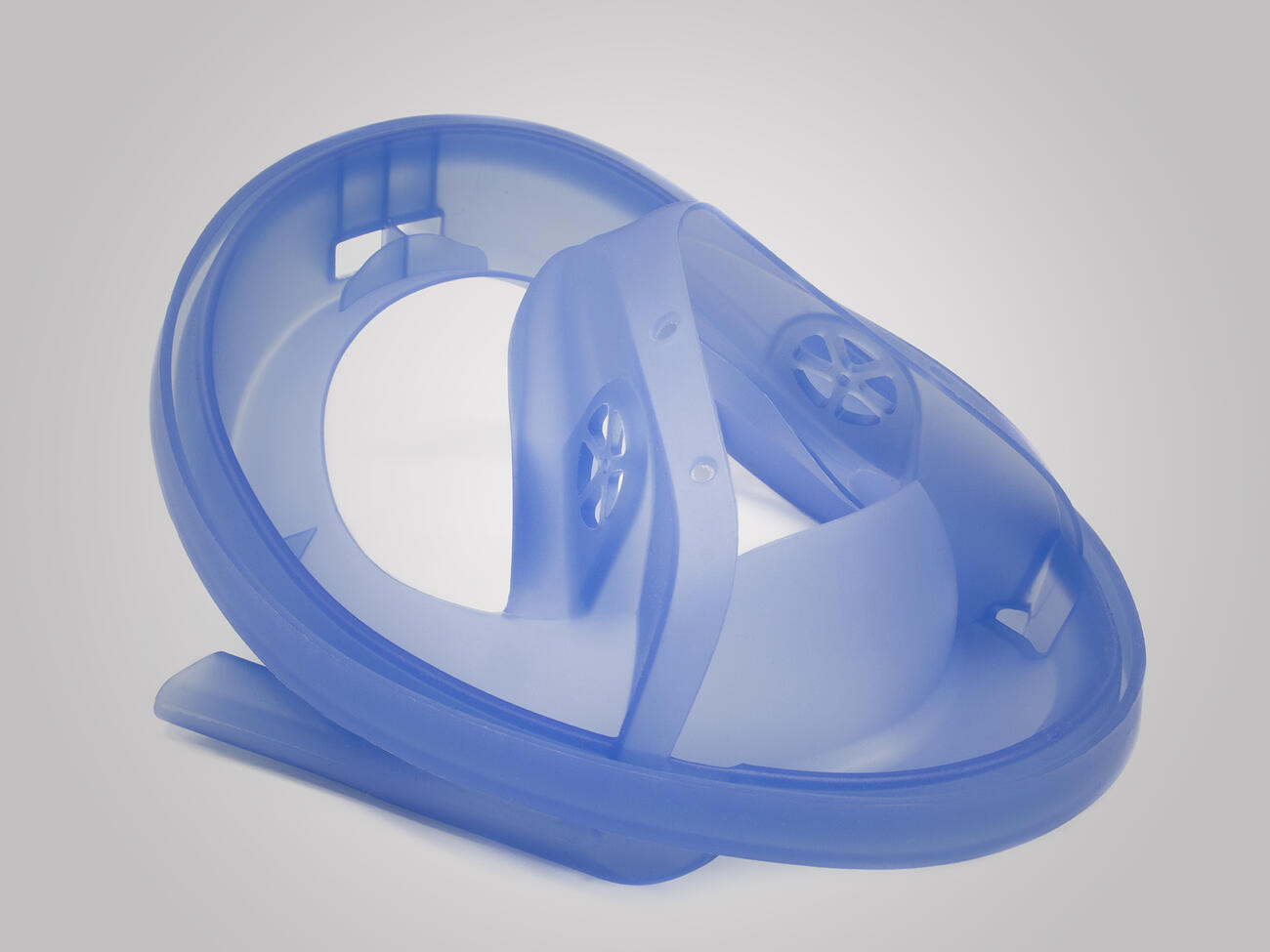

The multi-component version of the MicroPower, known as MicroPower Combimould, is equipped with two horizontally positioned injection aggregates and a rotary disk integrated in the machine. The rotary disk takes care of turning the part towards the second injection unit and back. The machine is also laid out for clean-room injection molding. Its rotary disk is completely encapsulated. All connections for heating aggregates, temperature sensors, water tempering, core pull pneumatics and sensors, as well as the blow-through valve, are installed close to the rotary disk. The resulting short connection lines to the mold enhance the machine’s user friendliness.

At the Compamed, WITTMANN BATTENFELD will demonstrate its know-how in the field of LSR processing in micro part production by manufacturing a support ring with a silicone membrane from PC and LSR on a MicroPower 15/10H/10H Combimould. The materials to be used for this purpose are polycarbonate (Macrolon) from Covestro and a self-adhesive LSR (Silopren) supplied by Momentive. The mold has been constructed in co-operation with Nexus. The LSR metering device actually comes from Nexus and is equipped with a new Servomix liquid dosing unit for LSR with an OPC-UA interface (Euromap 82.3).

Downloads