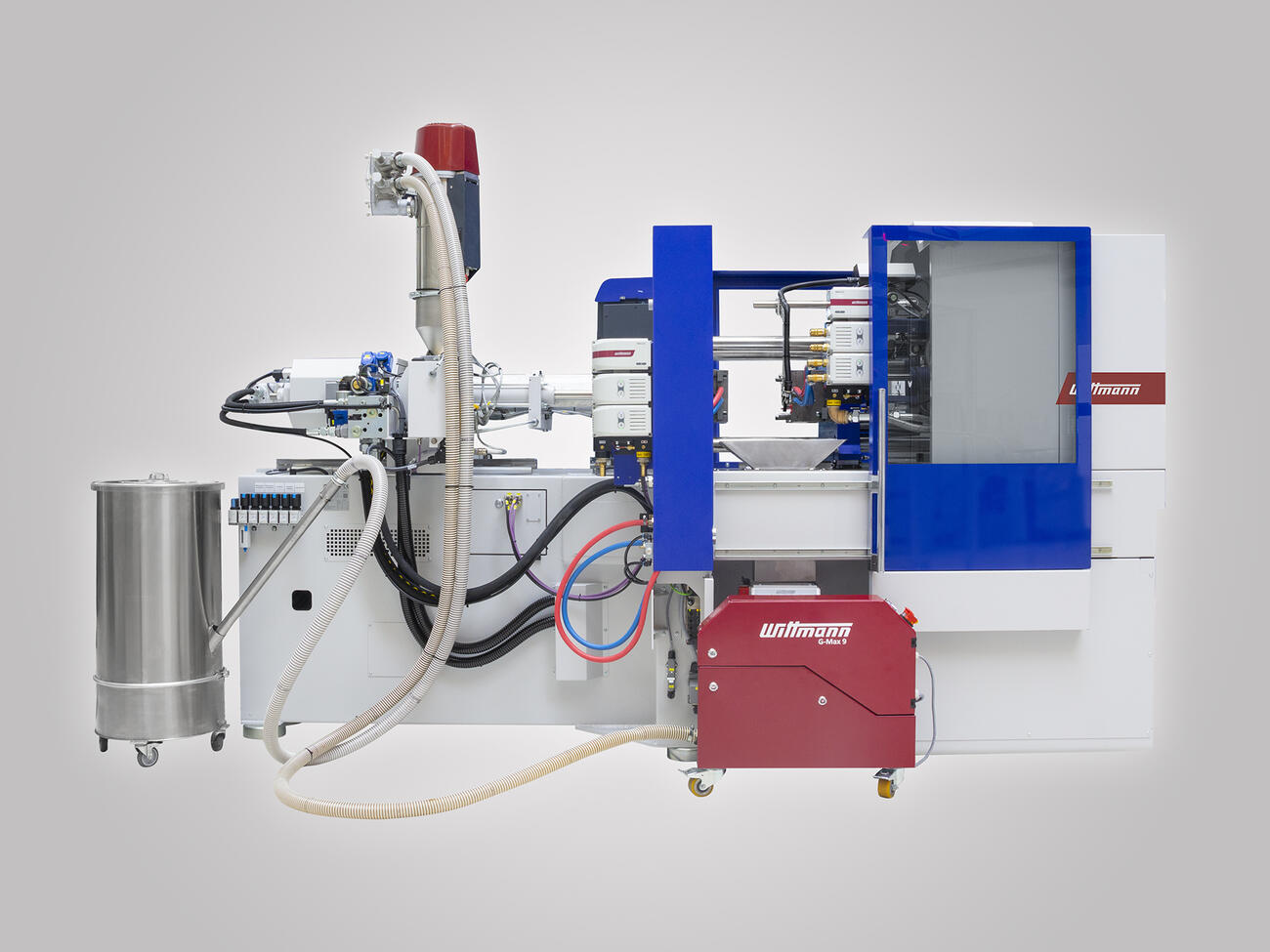

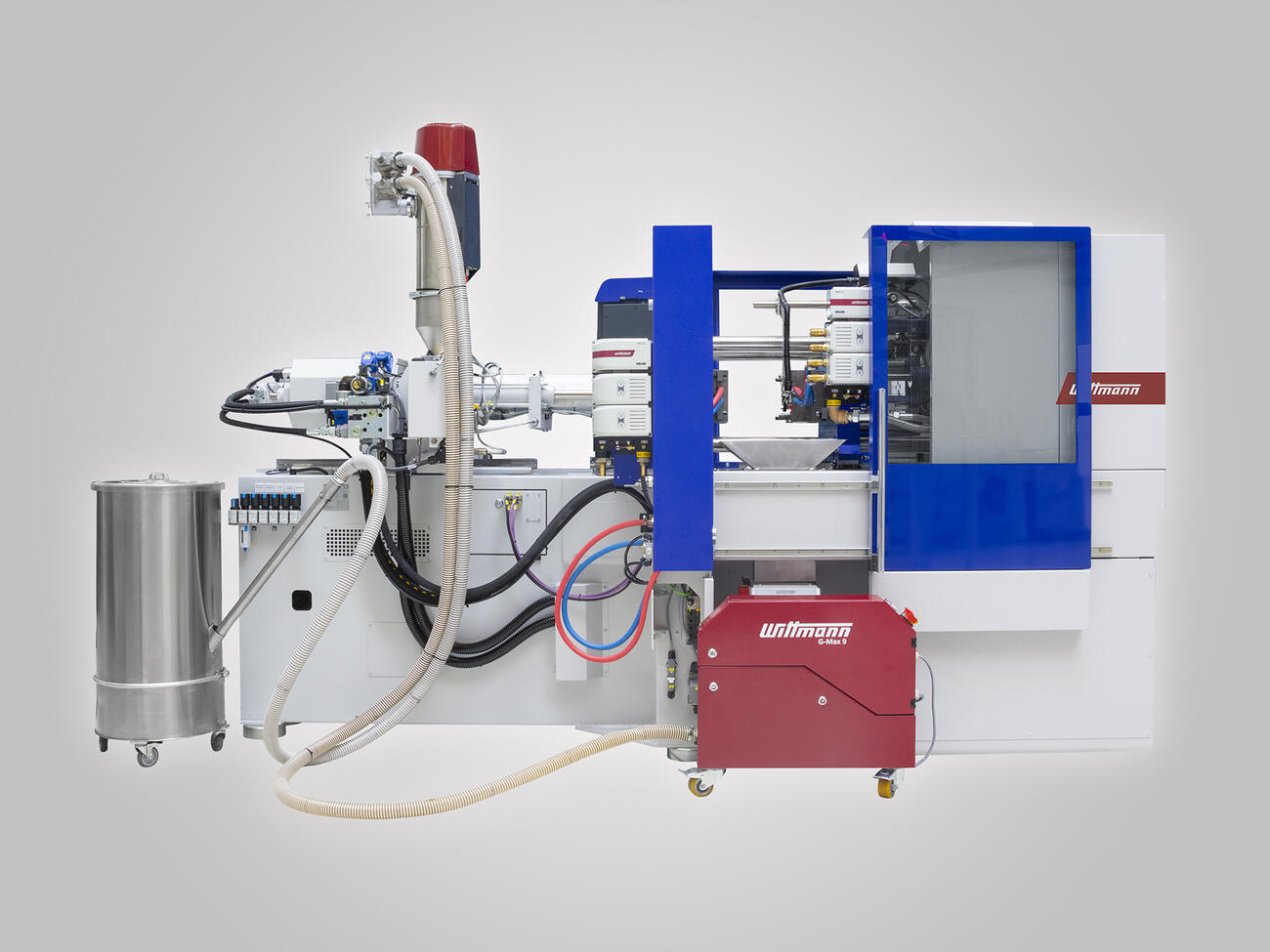

Ingrinder WorkCell

Ingrinder WorkCell

eco-friendly | practical | simple

Ingrinder package

The Ingrinder solution is designed for smaller injection molding machine models from the EcoPower and SmartPower series, since these machines are used in particular together with molds incorporating cold runner technology, thus producing sprue which must either be scrapped or passed on to a recycling system following injection molding.

Using the Ingrinder yields numerous benefits:

- Integration of the auxiliaries into the production cell gives the user a CE-certified system with a significantly smaller footprint than would be possible with a non-integrated solution. Depending on the machine model, the amount of space saved by using the Ingrinder is approx. 400 to 600 mm.

- The regrind is mixed in during the production process. In addition to the cost savings realized by using the regrind, additional cost cuts are achieved with hygroscopic materials, since the material has no time to absorb water, and consequently is still dry within the cycle when it reaches the granulator, which means that it need not be dried again prior to grinding.

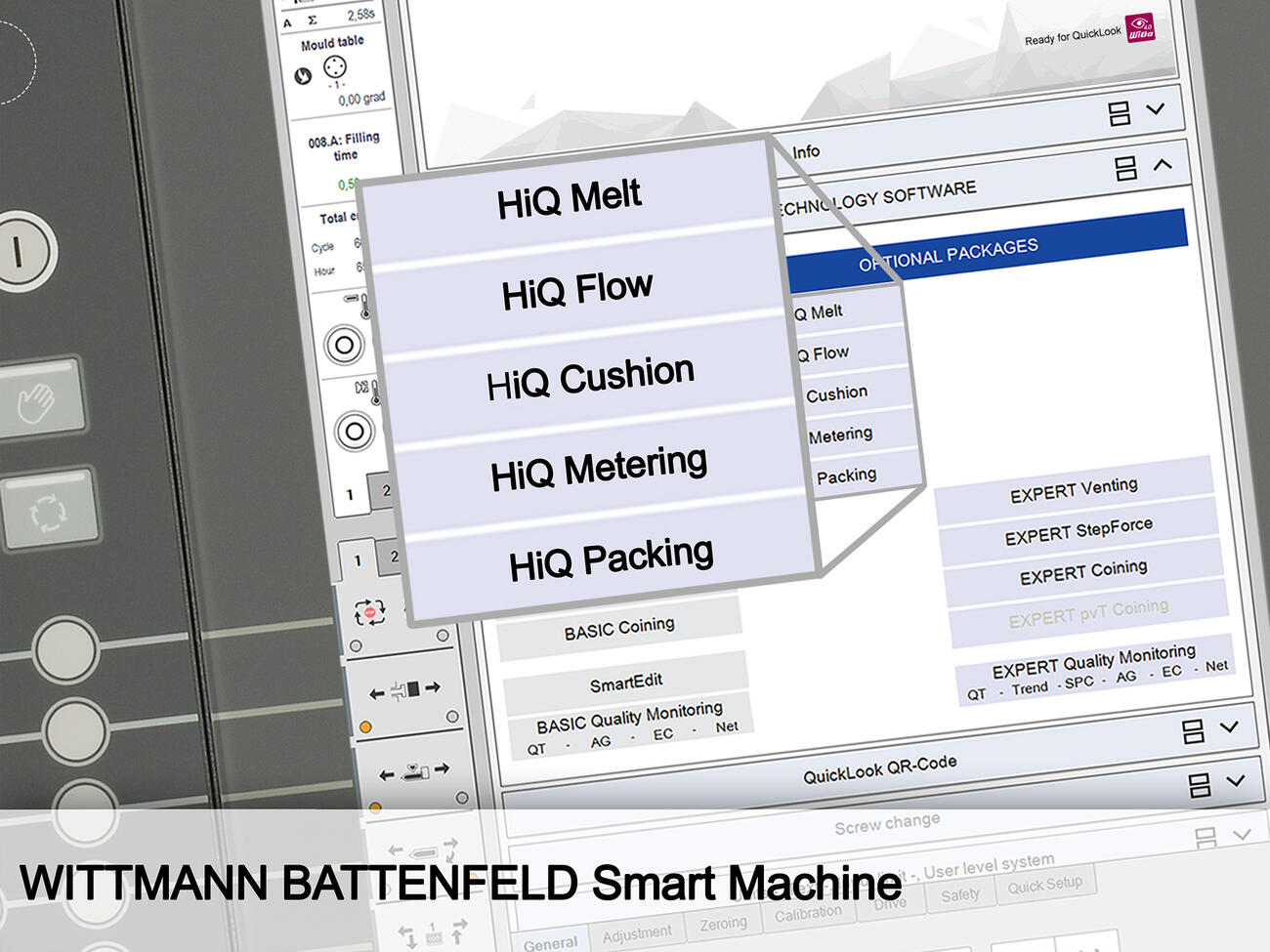

- Using the HiQ Flow® application software increases process reliability.

- The system can be extended easily into a Wittmann 4.0 cell with additional auxiliaries and the WITTMANN TEMI+ MES solution.

Downloads