Fakuma 2021 retrospective

Fakuma 2021 retrospective

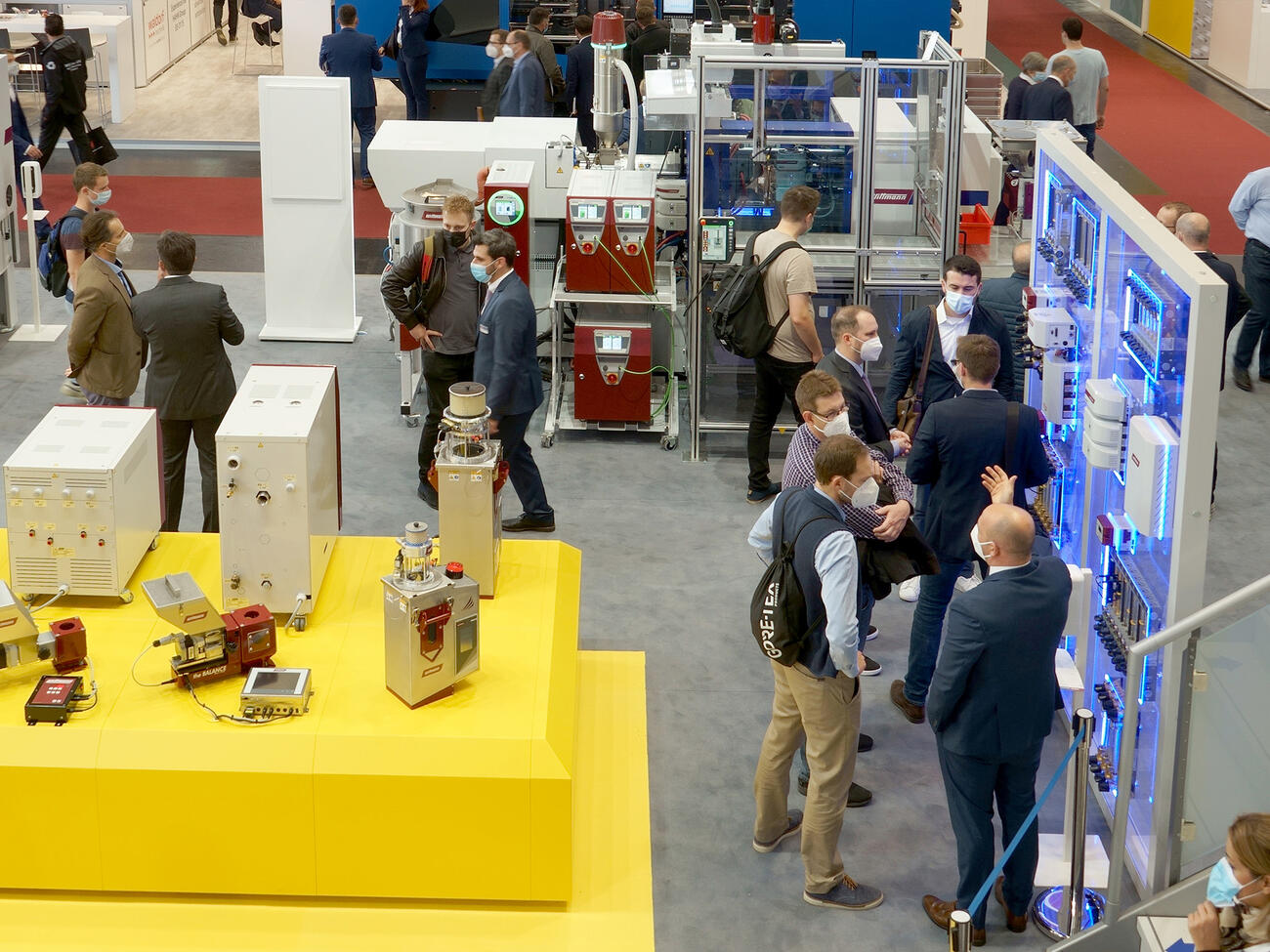

For WITTMANN BATTENFELD, the focus at FAKUMA 2021, which took place in Friedrichshafen from October 12th to 16th, was on sustainability, economic efficiency and future technologies. Numerous regular customers as well as new interested parties visited the booth.

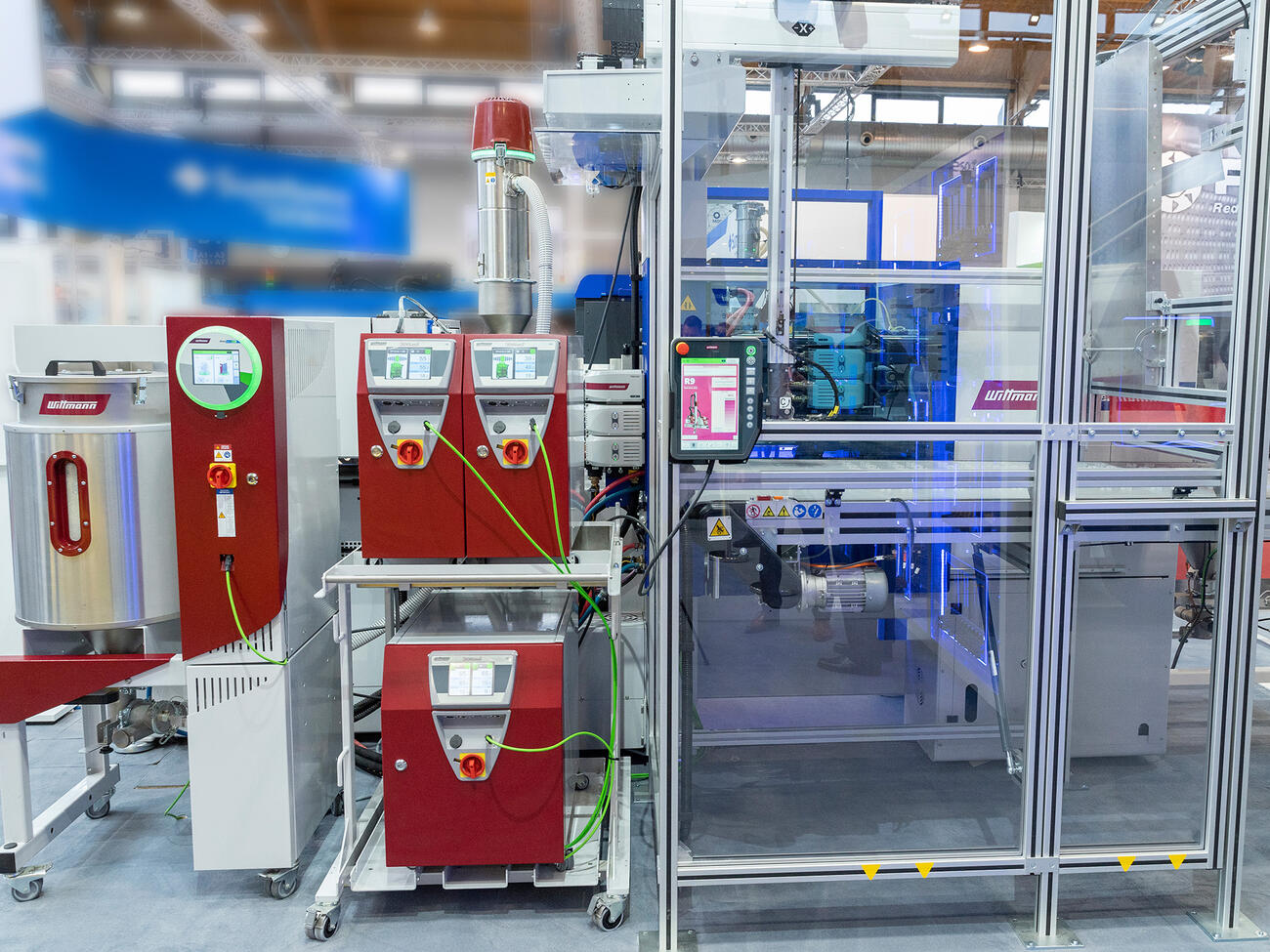

Many highlights aroused great interest. Among them was the SmartPlus machine, which is characterized by its high level of cost-effectiveness, energy efficiency and repeatability. Thanks to the use of proven technologies and selected options, short delivery times and an excellent price-performance ratio can be offered with this machine.

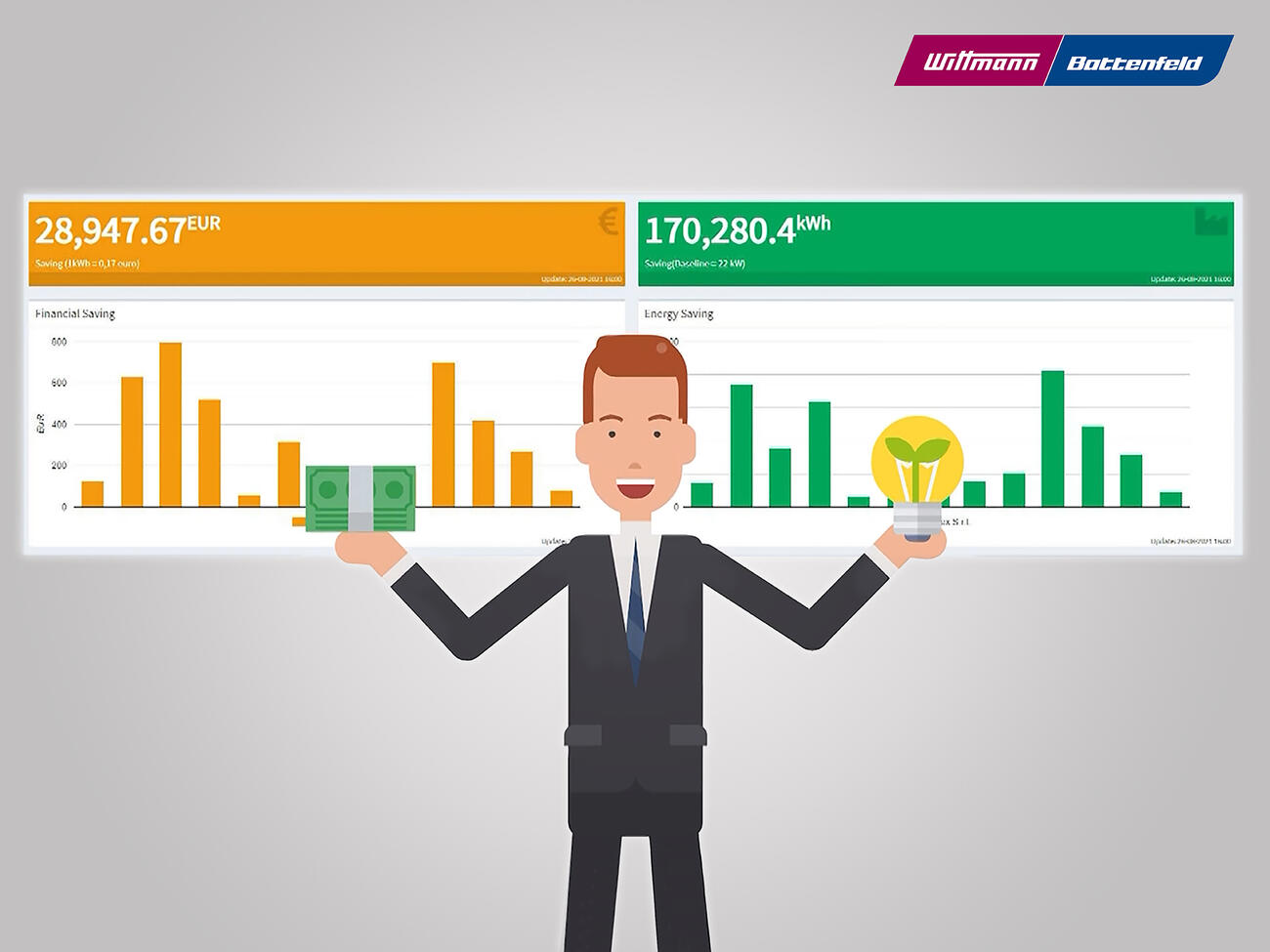

With IMAGOxt, WITTMANN BATTENFELD sets another mark in terms of sustainability. IMAGOxt allows the scalable display and visualization of energy consumption of connected machines, devices and any consumption clusters in the company. IMAGOxt includes numerous functions and tools to help show current energy consumption, graphically prepare historical trends and define key performance indicators (KPIs) and consumption targets. For example, IMAGOxt can be used to visualize real-time energy flows between different departments or consumption clusters. These consumption analyses help companies identify the real energy consumers within the company and thus help them achieve the savings targets set by the EU while maintaining financial sustainability and growth. Likewise, the program directly calculates CO2 consumption and energy savings already achieved. All calculated values can be stored in reports and are thus available for long-term analysis.

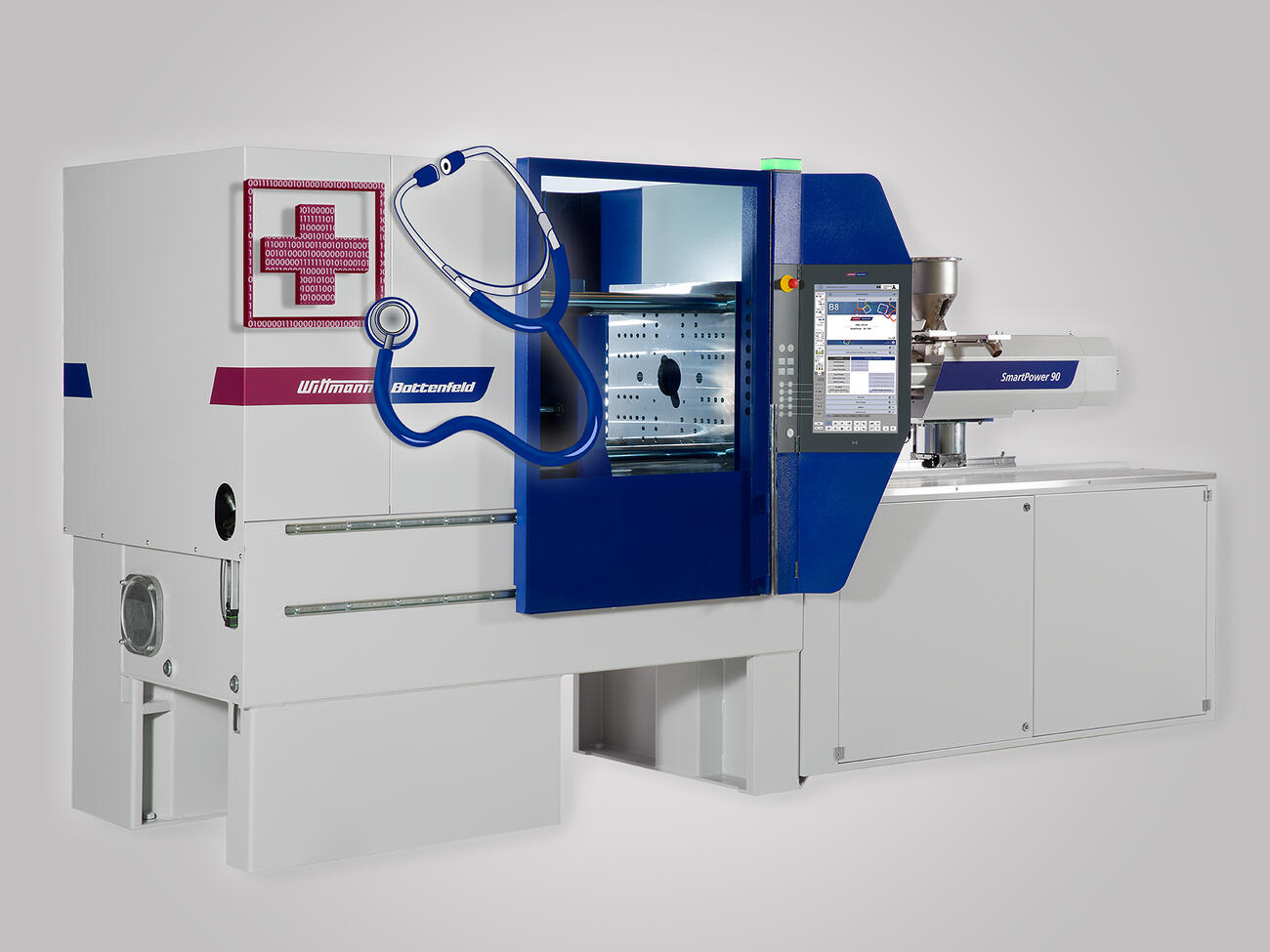

Another innovation, the Health Factor, uses easy-to-understand and robust key figures to provide a view of the health of the machine axles as well as the hydraulic pumps. This makes it easier to plan necessary machine maintenance, among other things. With this information, the maintenance or repair can not only be better planned in terms of time, but it is also carried out in a targeted manner for the respective axis or pump. The user can procure the necessary spare parts in good time and plan any machine downtime required for the repair in such a way that ongoing production is disrupted as little as possible.