Blenders

Blenders

Precision Blending

WITTMANN Blenders

Gravimax material blenders and Dosimax feeders are of highest precision and have the latest technology

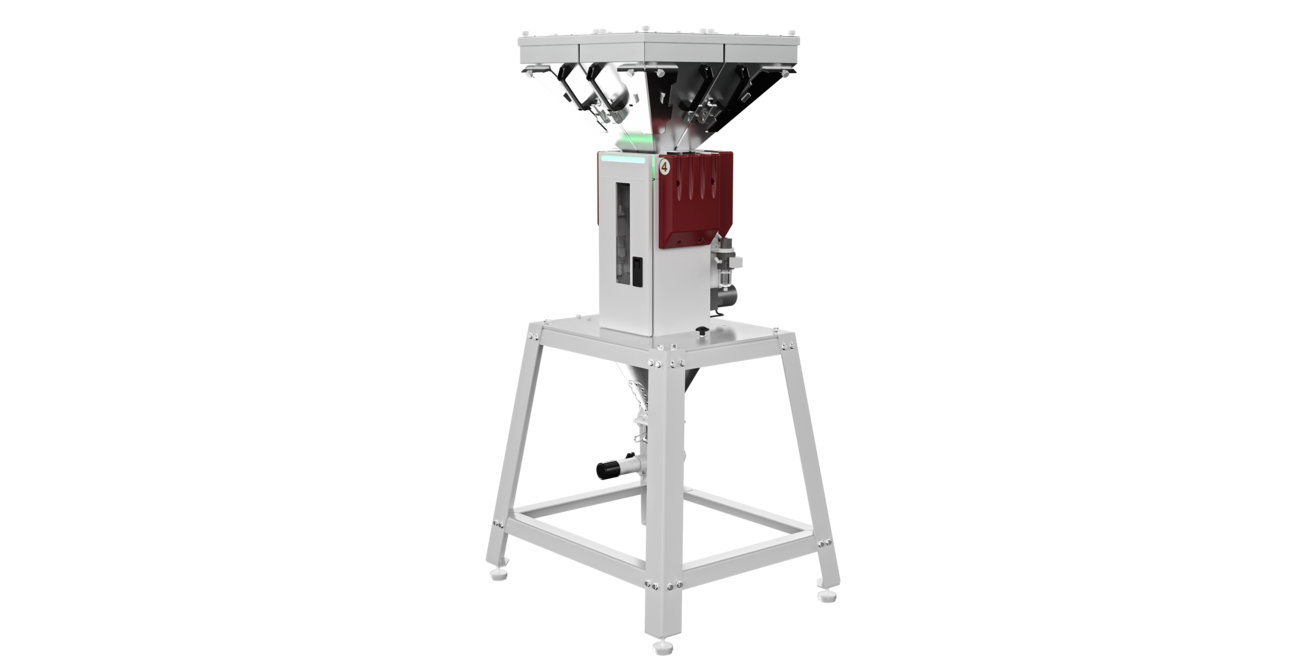

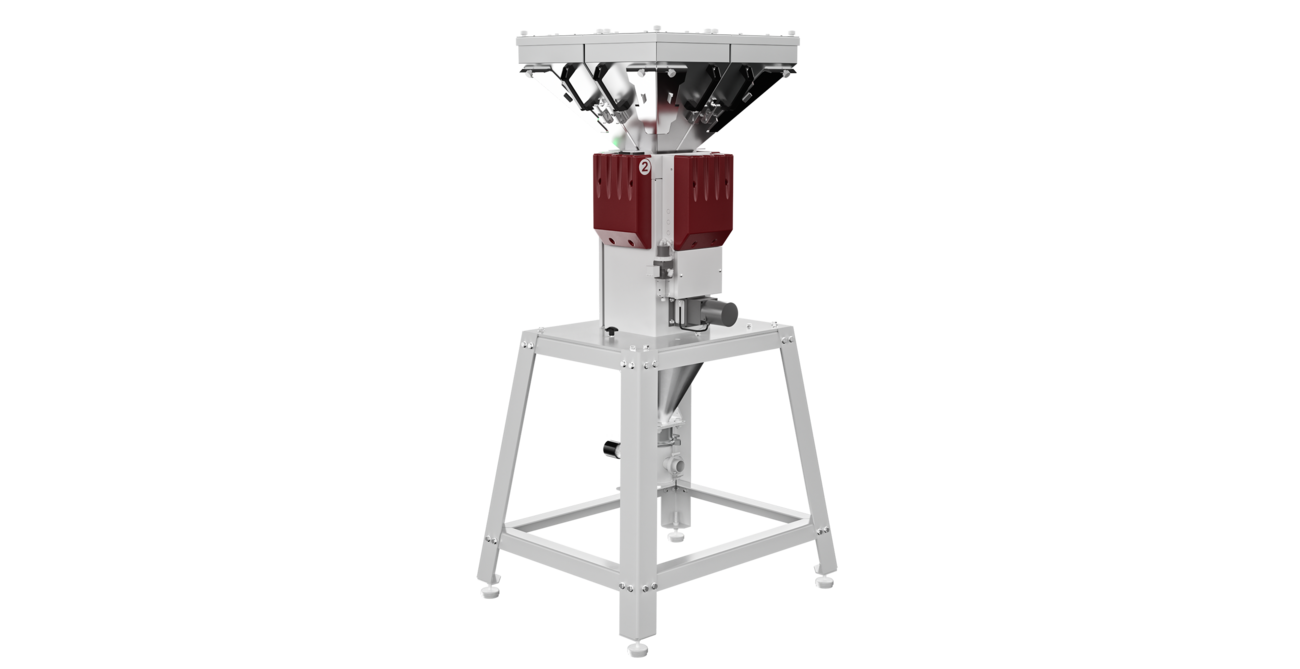

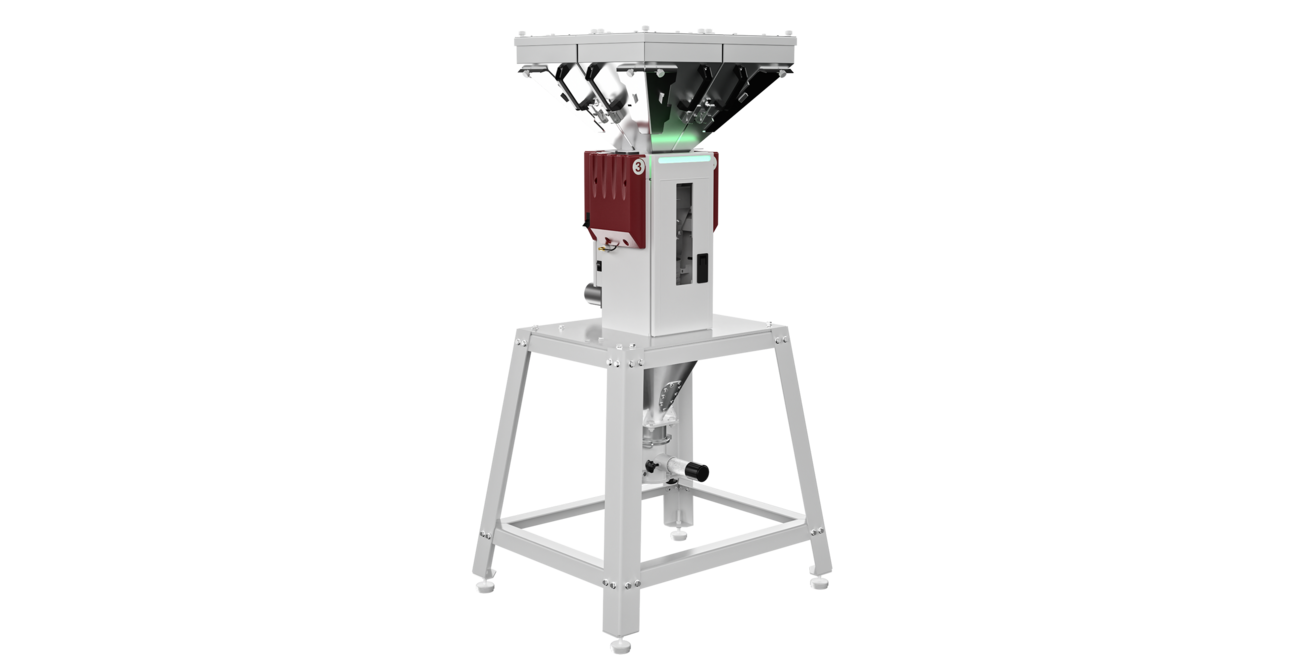

Gravimax Gravimetric Blenders

The Ultimate in Precision Blending

Gravimax blender models Series 1, 3, 7, 9, and 18/27 for batch sizes from 1 to 27 kg (2.2 to 60 lbs.)

Advantages of Gravimax Blenders

- Simple operation

- Highly precise metering valves made from stainless steel for high abrasive wear applications

- Interchangeable steel hoppers with self-closing valve mechanism

- “Clip-on” corner window provides full view for material inspection

- Easily removable weigh bin

- Uniform material blending using a highly efficient spiral mixer

- RTLS Technology uses progressively smaller dispensing algorithms to approach the target weight

Gravimax Touch-screen Control

- High-capacity microprocessor controller

- Designed for Simplicity, Ease-of-use and High Efficiency

- Control of up to 8 components

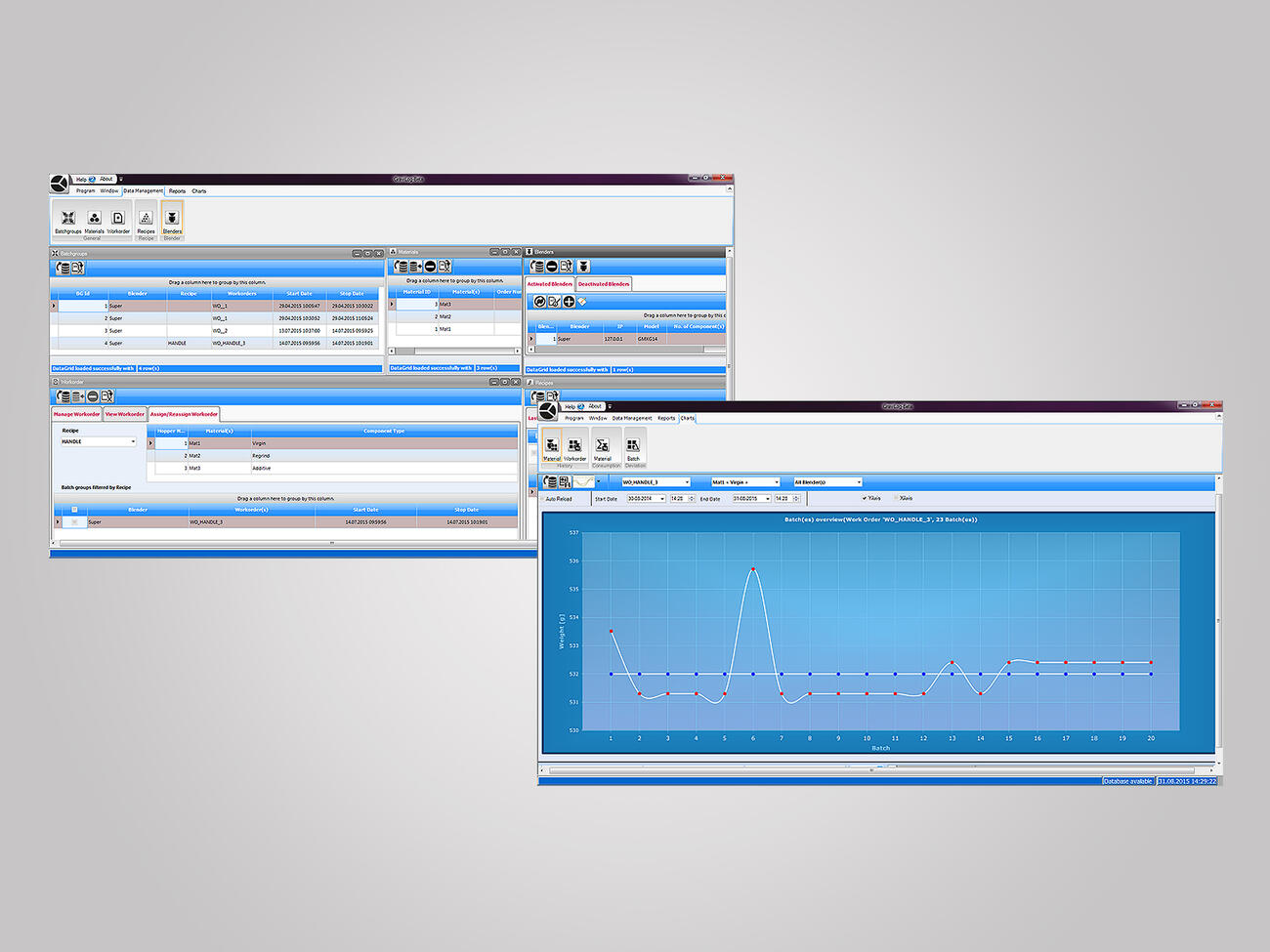

GraviLog is the name of a software solution that has been especially developed for data recording of gravimetric blenders of the WITTMANN Gravimax G series. This comprehensive software makes it easy to analyze various differing factors, for example the material consumption of several devices in regard to a special working process. And using GraviLog makes it possible to generate graphical representations for target and performance values.

Dosimax Volumetric Dosing Systems

Volumetric Dosing Systems with Dosing Cylinder

The dosing cylinder guarantees a uniform and repeatable flow throughout a wide range of applications. The specific design guarantees that the master batch is blended uniformly and precisely. The avoidance of any pulsing during blending provides maximum control of the process and the end product.

Dosimax MC Basic

- Digital revolution setting from 0 to 200 rpm within 0.1 rpm steps

- Digital time setting from 0 to 999 sec. within 0.1 sec. steps

- Timer mode for injection molding applications

- Keyboard lock: 1 level

- 4-digit, 7 segment LED at front display

- Man/machine interface via keypad foil

Dosimax MC 12 Additional Functions

- Neckpiece with cleaning door

- Quick material discharge slide gate

- Timer and relay mode for injection molding applications

Dosimax MC 18 Additional Functions

- Tachometer synchronization for extrusion applications

- Constant dispensing through automatic adjustment of rotation speed

- Integrated conveying control

Downloads